18650 Battery Pack

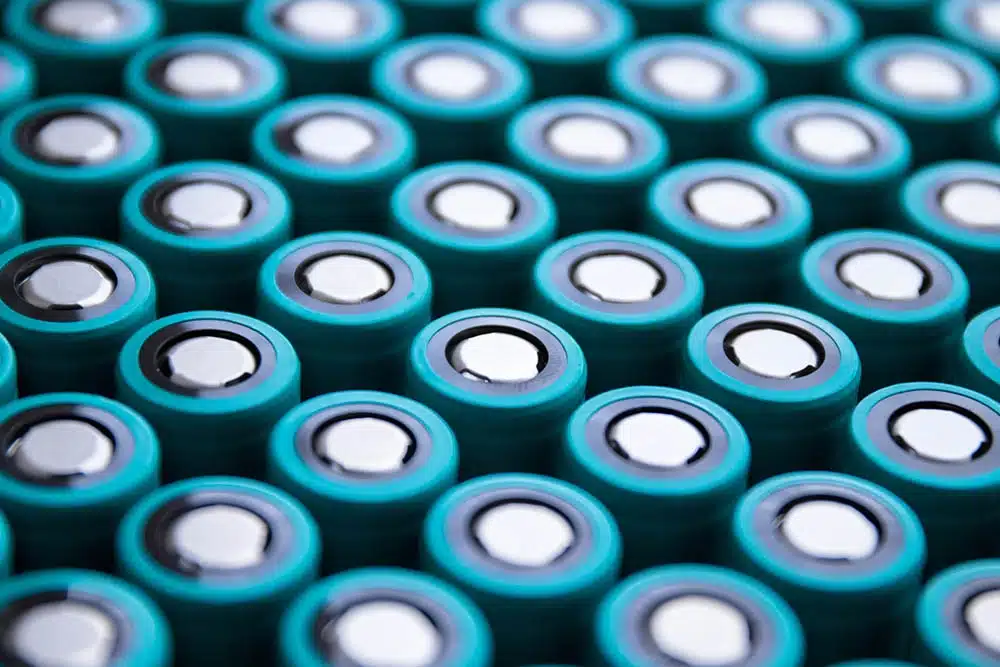

The 18650 lithium battery pack is composed of multiple 18650 lithium battery cells arranged in series and parallel to meet the voltage and runtime requirements of specific devices.

The dimensions of a single 18650 cell are: a cylinder with a diameter of 18mm and a height of 65mm.

Custom at any size. custom battery pack housing. Custom voltage from 3.7V-240V. Custom set up of battery BMS, RS232, RS485, CAN Bus protocols.

We custom 18650 battery packs for various devices. Feel free to contact us for inquiries.

High energy density

High energy density with small size, and lightweight.

Wide operation temperature

Suits -40℃ ~ +80℃ working temprature ranges

Low self-discharge rate

The self-discharge rate is approximately 5%.

Custom cylindrical batteries

Custom different cylinder battery in series and parallel combination.

18650 Battery ion Pack Product

Based on the overall performance and cost budget of the customer, we recommend different 18650 cell brands, such as Samsung, LG, Panasonic, and Sony for imported brands; for domestic brands, we have EVE, Lishen, and other various cells.

Below are some of the 18650 battery packs we produce, with voltages of 3.7V battery pack, 7.4V 18650 battery pack, 11.1 v 18650 battery pack, 14.8 v 18650 battery pack, 22.2V, and 25.9V battery pack. Of course, we can produce battery packs with higher voltages as well.

- 18650 Battery Pack Products

18650 1S1P 3.7V 2Ah Battery

Nominal voltage: 3.7V

Nominal capacity: 2000mAh

Rated energy: 7.4Wh

Charge current: 3.0C rate

Discharge current: 1.0C rate

Diameter: ≤19mm

Length: ≤68.0mm

18650 1S1P 3.7V 1800mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 1800mAh

Rated energy: 6.66Wh

Charge current: 1.0C rate

Discharge current: 1.0C rate

Diameter: ≤19.0mm

Length: ≤68.0mm

18650 1S1P 3.7V 2500mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2500mAh

Rated energy: 9.25Wh

Charge current: 2.0C rate

Discharge current: 1.0C rate

Diameter: ≤19.0mm

Length: ≤68.0mm

18650 1S1P 3.7V 2600mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2600mAh

Rated energy: 9.62Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Diameter: ≤19.0mm

Length: ≤68.0mm

18650 1S1P 3.7V 3000mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 3000mAh

Rated energy: 11.1Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Diameter: ≤19mm

Length: ≤68.0mm

18650 1S1P 3.7V 3500mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 3500mAh

Rated energy: 12.95Wh

Charge current: 1.0C rate

Discharge current: 2.0C rate

Diameter: ≤19.0mm

Length: ≤68.0mm

18650 2S1P 7.4V 2000mAh Battery

Nominal voltage: 7.4V

Nominal capacity: 2000mAh

Rated energy: 14.8Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤19.0mm

Width: ≤38.0mm

Length: ≤68.0mm

18650 2S2P 7.4V 4000mAh Battery

Nominal voltage: 7.4V

Nominal capacity: 4000mAh

Rated energy: 29.6Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤38.0mm

Width: ≤38.0mm

Length: ≤68.0mm

18650 2S3P 7.4V 6000mAh Battery

Nominal voltage: 7.4V

Nominal capacity: 6000mAh

Rated energy: 44.4Wh

Charge current: 1.0C rate

Discharge current: 2.0C rate

Thickness: ≤38mm

Diameter: ≤56mm

Length: ≤68.0mm

18650 2S9P 7.4V 22.5Ah Battery

Nominal voltage: 7.4V

Nominal capacity: 22.5Ah

Rated energy: 166.5Wh

Charge current: 1.0C rate

Discharge current: 2.0C rate

Thickness: ≤56mm

Width: ≤110mm

Length: ≤68.0mm

18650 3S1P 11.1V 2500mAh Battery

Nominal voltage: 11.1V

Nominal capacity: 2500mAh

Rated energy: 27.75Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤34.0mm

Width: ≤38.0mm

Length: ≤68.0mm

18650 3S2P 7.4V 5200mAh Battery

Nominal voltage: 11.1V

Nominal capacity: 5200mAh

Rated energy: 57.72Wh

Charge current: 1.0C rate

Discharge current: 1.0C rate

Thickness: ≤38.0mm

Width: ≤56.0mm

Length: ≤68.0mm

18650 3S4P 11.1V 10Ah Battery

Nominal voltage: 11.1V

Nominal capacity: 10Ah

Rated energy: 111Wh

Charge current: 1.0C rate

Discharge current: 2.0C rate

Thickness: ≤56mm

Width: ≤75mm

Length: ≤68.0mm

18650 4S1P 14.8V 2Ah Battery

Nominal voltage: 14.8V

Nominal capacity: 2Ah

Rated energy: 29.6Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤19mm

Width: ≤76mm

Length: ≤68.0mm

18650 4S2P 14.8V 4.0h Battery

Nominal voltage: 14.8V

Nominal capacity: 4Ah

Rated energy: 59.2Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤38.0mm

Width: ≤76.0mm

Length: ≤68.0mm

18650 4S4P 12.8V 10Ah Battery

Nominal voltage: 14.8V

Nominal capacity: 10Ah

Rated energy: 148Wh

Charge current: 1.0C rate

Discharge current: 1.0C rate

Thickness: ≤76.0mm

Width: ≤76.0mm

Length: ≤68.0mm

18650 6S2P 22.2V 5.2Ah Battery

Nominal voltage: 22.2V

Nominal capacity: 5Ah

Rated energy: 111Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤38mm

Width: ≤68mm

Length: ≤112.0mm

18650 7S2P 25.9V 4Ah Battery

Nominal voltage: 25.9V

Nominal capacity: 4Ah

Rated energy: 103.6Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤38mm

Width: ≤68mm

Length: ≤130.0mm

18650 10S4P 36V 10.4Ah Battery

Nominal voltage: 36V

Nominal capacity: 10.4Ah

Rated energy: 374.4Wh

Charge current: 1.0C rate

Discharge current: 1.0C rate

Thickness: ≤89mm

Width: ≤81mm

Length: ≤213mm

18650 10S3P 36V 6Ah Battery

Nominal voltage: 36V

Nominal capacity: 6Ah

Rated energy: 216Wh

Charge current: 1.0C rate

Discharge current: 1.0C rate

Thickness: ≤118.1mm

Width: ≤11.81mm

Length: ≤3.94mm

18650 14.8V 5.2Ah Battery Pack

Nominal voltage: 14.8V

Nominal capacity: 5.2Ah

Rated energy: 76.96Wh

Charge current: 1.0C rate

Discharge current: 3.0C rate

Thickness: ≤135mm

Width: ≤38mm

Length: ≤38mm

18650 12.8V 100Ah Battery Pack

Nominal voltage: 12.8V

Nominal capacity: 100Ah

Rated energy: 1280Wh

Charge current: 0.2C rate

Discharge current: 1C rate

Thickness: ≤135mm

Width: ≤70mm

Length: ≤85mm

18650 Li-ion Battery Pack Applicates

18650 rechargeable lithium battery pack are commonly used in a wide range of applications, including: electric vehicles, military devices, solar lighting, mobility scooter, medical devices, blood pressure monitor, and smart robotics.

Medical

Custom 18650 battery pack for advanced medical carts, fingertip pulse oximeters, heartstart monitors/defibrillators.

Smart Robotics

18650 battery packs are an excellent choice for powering smart robotics.

18650 Battery Pack Advantages

18650 lithium batteries are favored for their excellent performance and wide range of applications. The following are their main advantages:

- Long cycle life: 500+charge discharge cycles

- Lightweight design: Lightweight, suitable for various mobile devices.

- High discharge capacity: supports applications with instantaneous high power output, such as power tools and robots.

- High safety: Multiple safety protection measures: overcharge, overdischarge, short circuit, over temperature protection.

- Flexible combination: Different series or parallel combinations can be made according to your needs to meet your specific voltage and capacity.

18650 Battery Packs Product Listing

Below is a table of the 18650 rechargeable battery pack models we frequently ship. Some are regular discharge rates of 0.5C and 1.0C, while others have higher discharge rates of 3C, 5C, and 10C. Please refer to the specific product descriptions.

We offer free design services for 18650 custom battery pack, including cell selection, protection board design, structural design, and performance testing. Feel free to contact us with your lithium battery needs.

- 18650 Battery Pack Product

Model | Voltage (V) | Capacity (mAh) | Dimension (Thick*Width*Length) (mm) | Lifespan (25℃,0.5C,80%DOD) | Weight (g) | Protection Function | Know More |

|---|---|---|---|---|---|---|---|

HYT18650-1S1P-2Ah | 3.7 | 2000 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-1S1P-1.8Ah | 3.7 | 1800 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-1S1P-2.5Ah | 3.7 | 2500 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-1S1P-2.6Ah | 3.7 | 2600 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-1S1P-3Ah | 3.7 | 3000 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-1S1P-3.5Ah | 3.7 | 3500 | 19*19*68 | >500 | 50 | Yes | |

HYT18650-2S1P-2Ah | 7.4 | 2000 | 19*38*68 | >500 | 100 | Yes | |

HYT18650-2S2P-4Ah | 7.4 | 5200 | 38*38*68 | >500 | 200 | Yes | |

HYT18650-2S3P-6Ah | 7.4 | 7800 | 38*56*68 | >500 | 300 | Yes | |

HYT18650-2S9P-22.5Ah | 7.4 | 22500 | 56*110*68 | >500 | 900 | Yes | |

HYT18650-3S1P-2.5Ah | 7.4 | 2000 | 34*38*68 | >500 | 150 | Yes | |

HYT18650-3S2P-5.2Ah | 11.1 | 5200 | 38*56*68 | >500 | 300 | Yes | |

HYT18650-3S4P-10Ah | 11.1 | 10000 | 56*75*68 | >500 | 600 | Yes | |

HYT18650-4S1P-2Ah | 14.8 | 2000 | 19*76*68 | >500 | 200 | Yes | |

HYT18650-4S2P-4h | 14.8 | 4400 | 76*76*68 | >500 | 400 | Yes | |

HYT18650-4S4P-10Ah | 14.8 | 10000 | 76*76*68 | >500 | 800 | Yes | |

HYT18650-6S2P-5.2Ah | 22.2 | 5200 | 38*68*112 | >500 | 600 | Yes | |

HYT18650-7S2P-4Ah | 25.2 | 4000 | 38*68*130 | >500 | 700 | Yes |

18650 Battery Pack Manufacturers

- Minimum Order Quantity: 500 pieces per model.

- All orders come with the UL1642, UN38.3, CE, MSDS certificates.

- Hongyitai battery pack customization in terms of voltage, capacity, size, and charge/discharge rate.

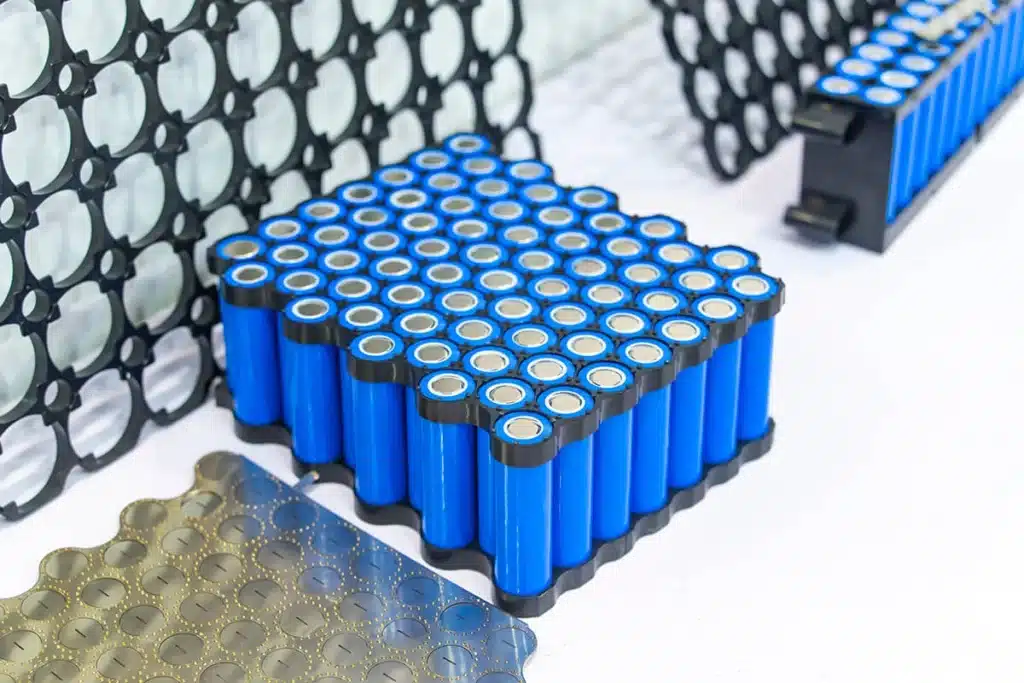

18650 Battery Pack Assembly

The assembly process of an 18650 battery pack usually includes the following steps:

18650 li-ion battery cell selection: Ensure that the selected battery cell brand and capacity are consistent, and the internal resistance differential pressure is small.

- Battery management system: Our BMS can monitor more factors such as temperature, humidity, etc. We can even send data to a computer or application so that your customers can read the data on time.

- Structure design: During the assembly process, ABS brackets, ventilation design, and integrated protective plates are used to ensure optimal performance of the battery pack.

- Assembly: Place the battery cells, BMS, and insulation materials into a protective casing or wrap them with PVC.

How to calculate 18650 battery pack

The 18650 battery pack is formed by connecting multiple 18650 batteries in series (referred to as S), with each 18650 battery increasing its voltage to achieve the desired operating voltage (i.e., the total voltage of the battery pack). Parallel (P for short) connection obtains higher capacity by adding up the total ampere hours (Ah).

For consumer electronics batteries equipped with 11.1V 4Ah battery packs, typically three 3.7V 18650 battery cells are connected in series (3S) to achieve nominal 11.1V, and two are connected in parallel (2P) to increase capacity from 2Ah to 4Ah. You will find that this configuration is called 3S2P, which means three units are connected in series and two units are connected in parallel.

18650 Battery Pack Diagram

18650 battery packs are formed by connecting multiple 18650 cells in series (S), with each cell increasing the voltage to reach the required total nominal voltage. Parallel (P) connections add the battery diagram capacities in Ah to achieve the needed capacity.

Left is a simple diagram of our 18650 battery packs in series and parallel configurations. Series connection means connecting the positive and negative terminals of each cell, while parallel connection means connecting the positive terminals together and the negative terminals together.

Besides these basic 18650 battery details, we also need to consider protection board design and placement, whether a casing is needed, or if simple PVC wrapping will suffice. Since lithium batteries are the main power source for the entire device, we must ensure their safety and reliability. We are a professional lithium battery factory in China, welcome to consult with us to solve your problems.

FAQs for 18650 battery pack

- Cell insulation: Insulate each cell with specialized fish paper.

Arrange the 18650 cells according to the series and parallel requirements, preferably using a fixed holder to prevent the cells from moving.

- Use nickel strips and a welding machine to weld the batteries. In series connections, connect the positive terminal of one cell to the negative terminal of the next cell. In parallel connections, connect the positive terminal of one cell to the positive terminal of the next cell to form the required battery module.

- Weld the protection board to the main positive and main negative terminals of the cells. If there are communication wires, connect them in a specific order to ensure the welding is secure and not easily dislodged.

- Wrap the battery pack with PVC or place it in a battery case, securing it with hot melt glue or 3M tape. Ensure the battery has some space for heat dissipation.

- Use a multimeter to test the voltage and internal resistance of the entire battery pack to ensure normal output.

This is an example of a 12V battery pack made from 18650 cells, following the DIY battery pack process.

Preparation

- Insulate the positive terminal of each cell with fish paper.

- Use a multimeter to test the voltage of each cell, ensuring their voltage and internal resistance are consistent. It's best to also test the capacity to ensure minimal differences in these three values among the cells.

Design the Battery Pack Configuration

- This is a 3-series battery pack, resulting in a nominal voltage of 11.1V after connecting in series.

- This is a 3-series battery pack, resulting in a nominal voltage of 11.1V after connecting in series.

Welding the Batteries

- Use nickel strips and a spot welding machine to weld the batteries together. In series connections, connect the positive terminal of one cell to the negative terminal of the next cell, linking end-to-end.

- Use nickel strips and a spot welding machine to weld the batteries together. In series connections, connect the positive terminal of one cell to the negative terminal of the next cell, linking end-to-end.

Install the Battery Protection Circuit (PCM)

- Its role is to protect the battery from overcharging, over-discharging, short circuits, and to balance the cells. Connect the PCM to the battery pack, ensuring each connection is secure and reliable. The wiring design should be simple, reasonable, and effective.

- Its role is to protect the battery from overcharging, over-discharging, short circuits, and to balance the cells. Connect the PCM to the battery pack, ensuring each connection is secure and reliable. The wiring design should be simple, reasonable, and effective.

Assemble the Battery Pack

- Place the welded battery pack into a battery case, or use hot melt glue to fix the batteries together. Ensure there is enough space between the batteries for heat dissipation.

- Place the welded battery pack into a battery case, or use hot melt glue to fix the batteries together. Ensure there is enough space between the batteries for heat dissipation.

Testing and Charging

- Use a multimeter to test the voltage of the entire battery pack, ensuring the connections are correct. Use an appropriate charger (such as a 12.6V DC adapter) to charge the battery pack.

When choosing a suitable charger for a 12V 18650 battery pack, consider the following key factors:

Key Factors:

Voltage and Current Compatibility

- Ensure the charger supports the charging voltage and current for a 12V battery pack. Generally, the voltage for a 3-series battery pack is 12.6V, so the charger's voltage should be between 12V and 12.6V.

- Ensure the charger supports the charging voltage and current for a 12V battery pack. Generally, the voltage for a 3-series battery pack is 12.6V, so the charger's voltage should be between 12V and 12.6V.

Charger Output Current

- Typically, the charger's output current should be about one-third of the battery pack's total capacity. For example, for a 24V 18650 6Ah battery pack, the recommended charger current is 2-3A.

- Typically, the charger's output current should be about one-third of the battery pack's total capacity. For example, for a 24V 18650 6Ah battery pack, the recommended charger current is 2-3A.

Safety Features

- Choose a charger with safety features such as overcharge protection, short circuit protection, and reverse polarity protection to ensure safety during the charging process.

- Choose a charger with safety features such as overcharge protection, short circuit protection, and reverse polarity protection to ensure safety during the charging process.

Display Function

- Some chargers come with an LCD display that shows the battery's charging status, voltage, current, and other information, making it easier to monitor the charging process. Some chargers have an indicator light that turns from red to green. The charger lights up red while charging and turns green when fully charged.

- Some chargers come with an LCD display that shows the battery's charging status, voltage, current, and other information, making it easier to monitor the charging process. Some chargers have an indicator light that turns from red to green. The charger lights up red while charging and turns green when fully charged.

Based on our experience, we recommend using the Nitecore i2 Intellicharge, Xtar VC4SL, or contact us for other recommendations.

UN38.3 Certification

- The main test items include safety tests, altitude simulation, thermal tests, vibration, shock, short circuit, overcharge, and forced discharge. This is a necessary certification for the international transportation of lithium batteries.

- The main test items include safety tests, altitude simulation, thermal tests, vibration, shock, short circuit, overcharge, and forced discharge. This is a necessary certification for the international transportation of lithium batteries.

IEC 62133 Certification

- The latest standard is IEC 62133-2:2017. The test content includes short circuit, overcharge, thermal runaway, mechanical shock, vibration, external heating, and impact. This certification is commonly required by European countries.

- The latest standard is IEC 62133-2:2017. The test content includes short circuit, overcharge, thermal runaway, mechanical shock, vibration, external heating, and impact. This certification is commonly required by European countries.

UL2054 Certification

- A standard developed by UL Solutions, this certification is for battery packs and is an important certification for the North American market. It is very expensive.

- A standard developed by UL Solutions, this certification is for battery packs and is an important certification for the North American market. It is very expensive.

CE Certification

- This is a mandatory certification required by the European Union, mainly referring to CE-EMC certification, ensuring compliance with health and environmental standards. The CE mark is a necessary condition for entering the European market.

- This is a mandatory certification required by the European Union, mainly referring to CE-EMC certification, ensuring compliance with health and environmental standards. The CE mark is a necessary condition for entering the European market.

RoHS Certification

- RoHS usually involves destructive testing. Due to the special nature of batteries, we provide a battery directive instead to ensure that lithium batteries do not contain harmful substances such as lead, mercury, cadmium, etc.

- RoHS usually involves destructive testing. Due to the special nature of batteries, we provide a battery directive instead to ensure that lithium batteries do not contain harmful substances such as lead, mercury, cadmium, etc.

UL1642 Certification

- This is the UL1642 certification for battery cells.

There are indeed significant differences between different brands of 18650 lithium batteries, mainly in the following aspects:

Quality and Performance

- Renowned international brands like Samsung, LG, Panasonic, and Sony typically excel in battery quality and performance. Now, domestic brands like EVE and Lishen also offer good quality cells and are often the first choice for many power tools and energy storage products.

Application Fields

- Different brands of 18650 batteries may be optimized for different application scenarios. Some focus on power cells, while others focus on capacity cells.

Capacity and Performance Parameters

- Various brands of 18650 batteries differ in parameters like capacity, internal resistance, and continuous discharge rate. Some have a 1C rate, some have 3.0C, 5.0C, or even 10.0C rates. The main capacity range is between 1200mAh and 3500mAh.

- The lower the internal resistance, the stronger the battery's discharge capability. It is generally recommended to choose batteries with an internal resistance below 100mΩ.

Safety Performance

- High-quality brands usually invest more in safety features. For example, Panasonic's 18650 batteries are used by Tesla and have high safety performance.

Cycle Life

- Different brands have varying cycle lives. For example, imported cells generally have a cycle life of 800 cycles. The first-tier domestic companies' cells have a cycle life of around 500 cycles. Cheaper cells have a cycle life of around 300 cycles.

Price

- Imported cells from LG, Samsung, etc., are the most expensive. The higher the discharge rate, the higher the cell price.

18650 battery pack sample production takes 7 days, and mass production takes 15-20 days.