18650 lithium-ion batteries are a popular choice for many applications due to their high energy density. However, proper voltage management is critical for both performance and safety. This guide will cover core voltage concepts, charge status, and safety of use.

Table of Contents

Toggle18650 battery key voltage terms

To understand 18650 batteries in depth and use them safely and efficiently, you need to master the following key voltage concepts. They not only define the performance of the battery, but are also directly related to the battery life and safety.

Nominal voltage

The nominal voltage of 18650 batteries is usually 3.6V or 3.7V, which represents the “average voltage” of the battery during discharge. Just like each of us has a name, this voltage is the “identity card” of the battery, telling us the basic type of this battery. The reason why it is 3.6V or 3.7V is mainly determined by the chemical materials of the battery. Currently, most of them are nickel-manganese-cobalt (NMC). This voltage value is a balance point for engineers to try to make the battery discharge more power while ensuring safety. When you use it, you don’t have to worry too much about whether it is 3.6V or 3.7V, because for our common 18650 batteries such as NMC or INR, these two are basically the same thing, and your device will not be damaged by this small difference.

Charging voltage

For our common NMC/INR system batteries, 4.2V is 18650 battery voltage when fully charged. Charging voltage exceeding 4.2V may cause a series of irreversible electrochemical reactions, thus affecting the safety and service life of the battery. Specifically, excessive voltage will cause the precipitation of metallic lithium at the negative electrode, resulting in permanent loss of battery capacity, and may also form lithium dendrites, which will then pierce the diaphragm and cause internal short circuit. At the same time, excessive voltage will also cause the decomposition of the electrolyte, produce flammable gas, lead to increased internal pressure of the battery, and increase the risk of thermal runaway. In addition, the positive electrode material will also undergo structural changes under high voltage, release oxygen, react with the electrolyte, and accelerate battery aging and failure. Read more.

Therefore, it is recommended to use a high-quality charger with constant current/constant voltage (CC/CV) charging mode. They will first charge the battery with a constant current, and when the battery voltage reaches 4.2V, they will switch to constant voltage charging mode and gradually reduce the charging current until the battery is fully charged. This charging method can effectively avoid the risk of overcharging and ensure that the battery works in a safe and stable state.

Cut-off voltage

It is also the minimum voltage during discharge, usually between 2.5V and 3.0V. This voltage value can be regarded as a sign that the battery is “depleted”, but it does not mean that the battery is absolutely safe when discharged to this voltage. In fact, continuing to discharge below this voltage range will cause some damage to the battery. The current collector (usually copper) at the negative electrode of the battery may dissolve into the electrolyte. During subsequent charging, these dissolved copper may form deposits inside the battery, causing a short circuit. In addition, excessive discharge will destroy the SEI protective layer on the surface of the negative electrode. This protective film is crucial to the performance and life of the battery. Finally, excessive discharge will also cause irreversible changes in the structure of the positive electrode material, reducing the storage capacity of the battery.

Some battery specifications may indicate that 2.5V is the absolute cut-off voltage, but we generally do not recommend discharging the battery to this limit. In order to extend the battery life, we recommend that you stop discharging when the voltage drops to around 3.0V when the battery is under load. If conditions permit, 3.2V is more conservative and can better protect the battery.

Storage voltage

We recommend setting the storage voltage to between 3.7V and 3.9V. This voltage range roughly corresponds to 40%-60% of the battery capacity, which can effectively reduce the chemical reaction rate inside the battery and slow down the aging process. It should be noted that it is not recommended to charge the battery to 4.2V for long-term storage, because high voltage will increase the pressure of the electrolyte, accelerate the occurrence of side reactions, and lead to capacity loss and increased internal resistance. Similarly, it is not recommended to completely discharge the battery (below 3.0V), which may lead to the dissolution of the negative copper current collector and damage to the SEI layer. For most NMC/INR system 18650 batteries, 3.7V to 3.9V is usually a more ideal storage voltage range.

Ideal storage voltage range for different battery chemistries

The ideal storage voltage range for 18650 batteries of different chemical compositions is slightly different. For common NMC/INR system batteries, the recommended storage voltage is between 3.7V and 3.9V. For LiFePO4 batteries, the ideal storage voltage is around 3.2V. As for LiCoO2 batteries, which are relatively rare in 18650 batteries, their storage voltage is similar to that of the NMC system, and the recommended storage voltage is between 3.7V and 3.8V. However, in order to ensure the best storage effect, it is recommended that you refer to the data sheet provided by the battery manufacturer to obtain the precise storage voltage recommendation for the battery you are using.

NMC/INR: 3.7V – 3.9V

LiFePO4: approx 3.2V

LiCoO2: similar to NMC, 3.7V-3.8V

How to condition batteries to storage voltage

If your 18650 battery voltage is higher than the recommended storage voltage, you can use two ways: use the battery normally in the device until the voltage naturally drops to between 3.6V and 3.8V (this requires a multimeter to monitor the voltage). Or, use some dedicated chargers with a storage mode, which can discharge the battery to the set storage voltage.

If the battery voltage is below the storage voltage, you will need to charge the battery until it reaches the 3.7 V to 3.9 V range. Again, a multimeter can help you accurately monitor the voltage rise charging process.

18650 battery full operating voltage range

- 4.2V (Charging Voltage): This is the absolute upper limit of the charging voltage for 18650 batteries. During the charging process, the voltage will gradually rise from a lower value to 4.2V, indicating that the battery is fully charged.

- 3.6V/3.7V (nominal voltage): This is the middle value of the battery discharge curve and the voltage platform where the battery is in most of the working time.

- 3.0V (cut-off voltage): This is the minimum discharge voltage specified by the manufacturer. It is recommended to avoid discharging the battery to this voltage value, as excessive discharge may cause damage to the battery structure.

- 3.2V (recommended cut-off voltage): In order to extend the battery life, it is recommended to use 3.2V as the actual discharge cut-off voltage, and stop the battery from discharging when this voltage is reached.

- 3.6V-3.8V (storage voltage): This is the ideal voltage range for long-term storage of 18650 batteries. Within this voltage range, the chemical reaction rate inside the battery is low, which can minimize battery aging.

Voltage drop

Voltage drop is like the “small voltage fluctuation” when the battery is powering the device. Just like the water pressure decreases slightly when you turn on the tap, the battery voltage will drop to a certain extent as the device consumes more power. This is mainly because the battery has internal resistance. If the voltage drop is significant, it may be that the device is using too much power, the battery is running low, the battery itself is in poor condition, or there is a problem with the circuit connection. Choose the right 18650 battery to ensure stable voltage so that your device can work properly without obvious voltage drop problems. View more information.

18650 Voltage and State of Charge (SoC)

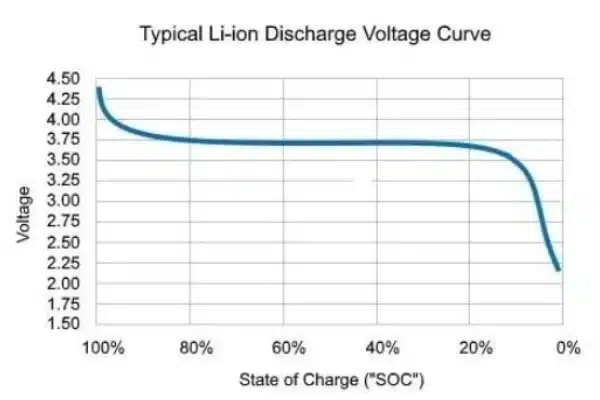

Want to know how much charge is left in your 18650 battery? Voltage is one of the key indicators. The state of charge (SoC) refers to the percentage of charge remaining in the battery. Although the relationship between voltage and SoC is not completely linear, the voltage can be used to roughly estimate the “full” level of the battery. A fully charged (no load, static) NMC/INR 18650 battery voltage is usually around 4.2V. As the battery discharges, the voltage will gradually decrease.

How to accurately judge the remaining capacity by voltage

The voltage graph (or discharge curve) shows the relationship between the voltage and the remaining capacity (SoC) of a specific battery under specific conditions (temperature, discharge rate). These graphs can usually be found in the battery data sheet. By looking at the voltage graph, you can find the approximate corresponding SoC percentage based on the current voltage value and the graph.

For example, a typical NMC 18650 discharge curve will show a relatively rapid drop in voltage at the beginning, followed by a long flat region where the voltage drops slowly, and finally a sharp drop in voltage again as the battery nears depletion.

Judging the remaining power of 18650 batteries based on voltage alone is sometimes inaccurate, mainly because the load and temperature will affect the voltage reading. The voltage will drop when the load is large, and too high or too low temperature will also cause voltage deviation. In addition, battery aging will also change the relationship between voltage and power. So we will take these factors into consideration to make an accurate assessment.

SoC vs Voltage

The table below shows SOV vs voltage for NMC and LFP batteries. The discharge curve of LiFePO4 (lithium iron phosphate) batteries is much flatter than that of NMC/INR (nickel manganese cobalt/nickel cobalt aluminum) batteries. The voltage variation of LiFePO4 batteries is very small, so it is more difficult to estimate SoC based on voltage alone. It is for reference only.

| SoC (%) | NMC/INR battery | LiFePO4 battery |

| 100 | 4.2V | 3.6V |

| 90 | 4.1V | 3.4V |

| 80 | 4.0V | 3.35V |

| 70 | 3.9V | 3.3V |

| 60 | 3.8V | 3.25V |

| 50 | 3.7V | 3.2V |

| 40 | 3.6V | 3.15V |

| 30 | 3.5V | 3.1V |

| 20 | 3.4V | 3.0V |

| 10 | 3.3V | 2.8V |

| 0 | 3.0V | 2.5V |

| 0 (destroyed) | 2.5V or less | 2.0V or less |

18650 batteries of different chemistries

18650 lithium battery has different voltages due to different internal chemical compositions. Below are the mainstream 18650 chemical compositions and their voltage characteristics.

- Nominal Voltage: 3.7V (some are also marked as 3.6V).

- Charging Voltage: 4.2V.

- Cut-off Voltage: about 2.5V (but it is generally recommended to avoid discharging below this voltage).

- Storage Voltage: 3.7-3.8V.

- Lithium cobalt oxide (LiCoO2) is now less used in 18650 batteries because of its lower energy density and safety risks compared to NMC.

- Nominal voltage: 3.2V.

- Charge voltage: 3.65V.

- Cut-off voltage: about 2.0V (but recommended to avoid; 2.5V or above is best).

- Storage voltage: about 3.2V.

- Advantages: safer than NMC/INR (less prone to thermal runaway), longer cycle life, wider operating temperature range.

- Disadvantages: lower energy density (less capacity for the same size), flatter discharge curve (harder to estimate remaining charge SoC).

- Nominal voltage: 3.6V or 3.7V.

- Charging voltage: 4.2V.

- Cut-off voltage: about 2.5V (but recommended to avoid; 3.0V or above is best).

- Storage voltage: 3.6V-3.8V.

- Advantages: A good balance between energy density, power output and safety. Most commonly used chemistry for 18650 batteries.

NCA batteries: Similar to NMC, but with slightly higher energy density and voltage. Used in some high-performance applications (e.g., Tesla batteries). Nominal voltage is about 3.6V, and charging voltage is about 4.2V.

LMO battery: Low energy density, but good thermal stability and high power output. Its nominal voltage is about 3.7-3.8V, and the charging voltage is about 4.2V.

Practical application of 18650 voltage

To ensure the safety and efficiency of the 18650 li ion battery charging process, please refer to the following 5 suggestions.

Use a dedicated charger: 18650 batteries must use a charger designed specifically for them. Universal power adapters or chargers for other types of batteries (such as NiMH batteries, lead-acid batteries) are not compatible with 18650 batteries and are strictly prohibited from being mixed. Incompatible chargers may cause battery damage, performance degradation, and even cause safety accidents.

Charging voltage: The charging cut-off voltage of common NMC/INR type batteries is usually 4.2 V, while the charging cut-off voltage of LiFePO4 batteries is 3.65 V. Using mismatched charging voltages may cause the battery to be overcharged or undercharged, affecting battery life and safety.

Constant current/constant voltage (CC/CV) charging mode: The ideal 18650 battery charger should adopt CC/CV charging mode. First, charge the battery with constant current (CC). When the battery voltage is close to the cut-off voltage of 4.2V, switch to constant voltage (CV) charging until the current gradually decreases to 0.2C rate, and charging is completed.

Choose a high-quality charger: It is recommended to buy a charger from a well-known brand that has passed safety certification. Poor-quality chargers may lack necessary protection circuits (such as overvoltage protection, overcurrent protection, overtemperature protection, etc.), posing a safety hazard.

Charging current selection: It is recommended to charge with the recommended charging current in the battery specification, such as 0.2C or 0.5C rating. Although a higher charging current can shorten the charging time, it may accelerate the battery capacity decay and shorten the battery life.

18650 voltage and safety

The voltage of 18650 batteries is a key indicator of their safety and performance. Improper voltage management can lead to serious consequences, so it is important to understand and pay attention to the following risks.

Consequences of overcharging

The most serious case is thermal runaway. It starts with a slight increase in internal temperature, but the process accelerates and eventually causes the temperature inside the battery to rise uncontrollably. This can lead to very dangerous consequences, such as battery fires, explosions, and the release of toxic gases, so it must not be ignored.

Secondly, the battery may also release gas and be accompanied by flames. This is because when overcharged, some unstable substances will be produced inside the battery, which may be released in the form of gas, and these gases are flammable and will burn when exposed to open flames.

Finally, overcharging itself can cause permanent damage to the battery and irreversible damage to its internal structure, leading to a decrease in battery capacity and shortened lifespan, affecting subsequent use.

In short, the consequences of overcharging 18650 batteries are very serious. At the very least, it will damage the battery, and at worst, it will cause a safety accident.

The dangers of overdischarge

The most direct impact is capacity loss. Excessive discharge will damage its internal structure, resulting in a smaller capacity to store electricity in the future, which means that you can use it for a shorter period of time. Moreover, this damage is irreversible, and once the battery capacity is lost, it cannot be restored.

Secondly, it also increases the risk of internal short circuits. You can imagine the inside of the battery as a delicate circuit. Excessive discharge can cause certain metal substances in the circuit (such as copper) to dissolve and then redeposit in places where they should not be, forming something like branches, which we call “dendrites.” This may pierce the isolation membrane inside the battery and cause a short circuit, just like wires touching each other directly, which is very dangerous.

Finally, the battery may become unstable and even pose a safety hazard. Its internal structure is already fragile, and if it is forced to charge, it may cause some unpredictable problems, such as heating, swelling, or even more serious accidents.

Protection circuit BMS

In order to solve safety problems such as overcharging and over-discharging of batteries, we usually equip the battery pack with a battery management system, referred to as BMS. This system is very important, it is the key to ensure battery safety and extend service life.

BMS is like an omnipotent guardian. It will always monitor the various states of the battery and take corresponding protective measures.

Overcharge protection: BMS is like a gatekeeper, always watching the battery voltage. Once it finds that the voltage of any battery cell has reached the maximum limit (such as 4.2V), it will immediately cut off the charging circuit, stop the battery from continuing to charge, and prevent overcharge.

Over-discharge protection: Similarly, the BMS will monitor the discharge process of the battery. If it finds that the voltage of any battery cell drops to the minimum limit (such as 2.5V or 3.0V), it will cut off the discharge circuit to prevent the battery from over-discharging.

Overcurrent protection: BMS also monitors the battery current. If the current is too large, BMS will cut off the circuit in time when the current exceeds the safe range to protect the battery from damage.

Short circuit protection: If a battery short circuits, it is like the positive and negative poles of a wire touching each other directly, which can have serious consequences. BMS can quickly cut off the circuit at the moment of a short circuit to prevent accidents.

Temperature protection: Batteries are also sensitive to temperature. Being too hot or too cold will affect its performance and safety. BMS monitors the temperature of the battery in real time. Once it finds that the temperature is too high or too low, it will take measures, such as stopping charging and discharging, to ensure that the battery operates within a safe temperature range.

Cell balancing: For a battery pack consisting of multiple cells, another important function of BMS is cell balancing. You can think of the battery pack as a barrel. How much water it can hold depends on the shortest plank. The role of cell balancing is to ensure that the voltage of all cells is consistent, just like each plank of the barrel is the same height, so that the performance of the battery pack can be fully utilized and its service life can be extended.

Summarize

In summary, it is important to understand and keep in mind the above key voltages of 18650 batteries. Be sure to use a high-quality charger and BMS, avoid overcharging and overdischarging, store properly, and handle the battery carefully, paying attention to any abnormal conditions. It is strongly recommended that you consult the data sheet provided by the battery manufacturer to obtain the most accurate specification information and follow safety recommendations. Proper use and maintenance can maximize the safety and life of the battery.