2000mAh ~ 5000mAh Polymer Battery

Polymer lithium batteries with capacities ranging from 2000mAh to 5000mAh are a type of high energy density and lightweight battery, widely used in various medium and large portable electronic devices. These batteries offer high safety, flexible customization, and long lifespan, making them suitable for applications requiring high-performance power sources.

Batteries in the 2000mAh to 5000mAh range may include up to 100 different polymer battery models. They support different discharge rates such as 3.0C, 5.0C, and 10.0C.

On the right are products that use polymer batteries, such as portable medical devices, drones, and remote control toys. Please feel free to inquire about your specific battery requirements.

High Energy Density

Mass energy density: 100-265 Wh/kg Volume energy density: 250-730 Wh/L

Big Size

The size is big to support long time discharge time.

Lightweight

40% lighter than steel shell lithium batteries of the same capacity, and 20% lighter than cylindrical aluminum shell lithium batteries.

Flexible in size

We can design the battery's size and capacity based on its charge & discharge rate to fit specific device spaces.

Lithium Polymer Battery Model

Below are some of the lithium batteries we produce in the capacity range of 2000mAh to 5000mAh. Each battery comes with a protection board and electronic wires, and has overcharge, over-discharge, and short circuit protection features.

Hongyitai not only produce 5000mAh battery, we can also design high capacity batteries.

- 3.7V 2000mAh ~ 5000mAh Lipo Battery

505080 3.7V 2000mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2000mAh

Rated energy: 7.4Wh

Thickness: ≤5.0mm

Widness: ≤50.0mm

Length: ≤80.0mm

Internal resistance: ≤50mΩ

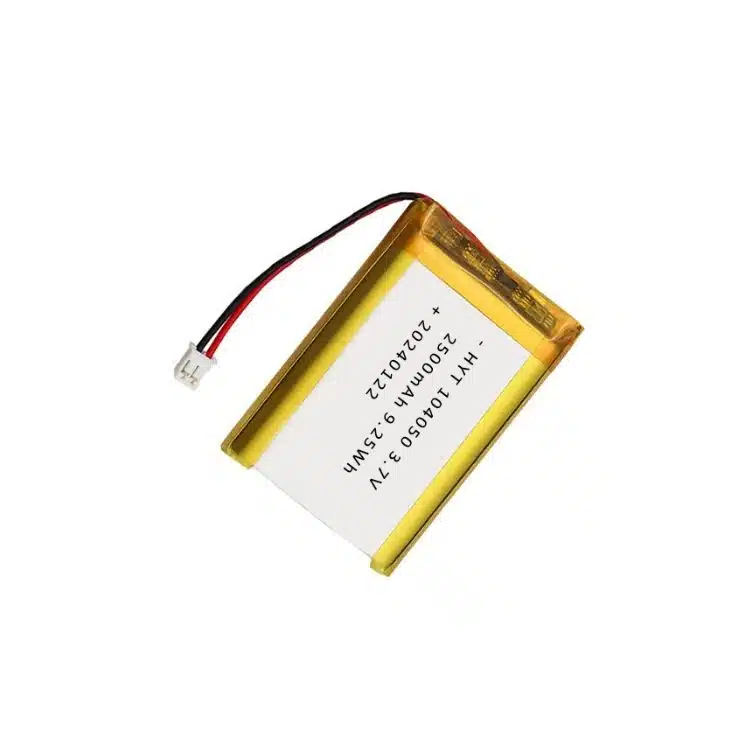

104050 3.7V 2500mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2500mAh

Rated energy: 9.25Wh

Thickness: ≤10.0mm

Widness: ≤40.0mm

Length: ≤50.0mm

Internal resistance: ≤60mΩ

Lithium Polymer Battery Application

- MRI Scanners: Provide portable power for wearable MRI devices, enabling diagnosis anytime, anywhere.

- Wearable Drug Delivery Devices: Supply stable and reliable power for devices like insulin pumps and pain relief pumps, ensuring timely medication delivery.

- Telemedicine Devices: Provide long-lasting power for wearable devices and portable instruments in telemedicine systems.

Drones and Remote Control Toys:

- Professional Aerial Drones: Deliver powerful energy for high-performance aerial drones, meeting the needs of professional photography and videography.

- Agricultural Drones: Provide long-lasting power for large agricultural drones, supporting precision farming and efficient operations.

Smart Home Devices:

- Smart Door Locks: Provide stable power support for smart door locks, ensuring home security.

- Household Robots: Supply long-lasting power for household robots like vacuum cleaners and cleaning robots, freeing up your hands and improving home cleaning efficiency.

- Virtual Reality (VR) / Augmented Reality (AR) Devices: Provide powerful energy needed for immersive experiences with VR/AR headsets.

How we produce polymer lithium ion battery

Below is our factory lithium polymer battery manufacturing 4 main processes. It includes from raw materials to final battery product.

Electrode Preparation:

- Mixing: Combine the electrode active material with solvents, conductive agents, binders, and other components to create a slurry.

- Coating: Evenly coat the electrode slurry onto the current collector.

- Rolling and Cutting: Roll and cut the material into electrode sheets.

Cell Assembly:

- Winding: Wind the positive and negative electrode sheets with the separator in a specific order to form the cell.

- Baking: Vacuum bake the wound cells to remove moisture.

- Electrolyte Injection: Inject the predetermined electrolyte into the cells.

- Packaging: Place the cells into aluminum-plastic film packaging and vacuum seal them.

Battery Formation:

- Formation: Perform the initial charge and discharge of the battery to form the SEI film and activate the battery.

- Capacity Grading: Screen and classify the batteries based on their capacity.

Cell Tab Welding and Wiring:

- Add PCM: Based on the charge and discharge requirements, the pre-designed protection board and electronic wires (terminal wires) are spot welded to the cell.

- Test: The battery is then tested using a comprehensive battery tester to check voltage, internal resistance, and protection board performance parameters. Finally, it undergoes aging.

3.7V lithium polymer battery Model

Hongyitai is a lithium battery manufacturer in China, and it starts from 2000mAh to 5000mAh capacity models. You can review many lipo battery models from below listing.

- 3.7V 2000mAh ~ 5000mAh lithium polymer battery

Model | Voltage (V) | Capacity (mAh) | Dimension (Thick*Width*Length) (mm) | Lifespan (25℃,0.5C,80%DOD) | Weight (Kg) | Protection Function | Know More |

|---|---|---|---|---|---|---|---|

HYT605080 | 3.7 | 3000 | 6*50*80 | >500 | 55 | Yes | |

HYT104050 | 3.7 | 2500 | 10*40*50 | >500 | 51 | Yes | |

HYT505080 | 3.7 | 2000 | 5*50*80 | >500 | 46 | Yes | |

HYT555368 | 3.7 | 2500 | 5.5*53*68 | >500 | 50 | Yes |

Lithium Battery Factory-direct Pricing

- Minimum Order Quantity: 1,000 pieces per model.

- All orders come with the necessary certificates.

- Any model can be customized in terms of voltage, capacity, size, and charge/discharge rate.

Features of Polymer Lithium Battery Chargers

- Charging Characteristics:

Need to match the charging characteristics of polymer lithium batteries, capable of completing the three stages of pre-charge, constant current charging, and constant voltage charging.

- Charging Voltage:

Generally between 4.15V and 4.28V. The charging current is set according to the battery capacity, with common specifications being 0.5A, 1A, and 2A. There are also specifications for US, EU, and Japan standards.

- Safety Protections:

Include multiple safety protection functions such as overcharge protection, short circuit protection, and temperature protection.

- User-Friendly Designs:

Some chargers integrate features like power indicators and mainstream interfaces like Type-C.

According to the charging current size and charging method, they can be divided into:

- 500mAh~2000mAh Low Current USB Chargers: Current is generally around 1A or 2A, making them convenient to carry.

Polymer Lithium Battery Charging Precautions

- Choosing the Right Charger: Select a charger with the appropriate specifications to match the battery’s voltage and capacity parameters.

- First-Time Use: The battery needs to be activated during the first use. It is recommended to fully charge with a low current and then discharge, repeating the cycle 1-2 times.

- Temperature Conditions: Pay attention to the temperature conditions during charging, generally suitable between 0-40°C.

- Avoid Overcharging and Overdischarging: To prevent damage to the battery, do not overcharge or overdischarge.

Why select us as lithium polymer battery supplier

Hongyitai has been producing polymer batteries for over 10 years, with hundreds of battery models and various material systems. We have a comprehensive set of production facilities, including a testing center, R&D center, certification center, sample center, and inspections at all stages of production. After shipment, we provide an inspection report for the batch of goods. The data and images you see will be exactly the same as the batteries you receive.

- 10 Years Experience: Over 10 years working experience in polymer battery field.

- Free Samples: Provide 7 days free samples freely.

- Certified: Provide UL1642, IEC62133, UN38.3, MSDS, CE certificates as it is ready.

- Full Models Available: Produce no matter which li-polymer battery you want.

- Tech Support: Before production, our engineer team will guide and evaluate your battery requiments.

The following is a simplified description of our lithium polymer battery manufacturing process:

1. Mixing

Make a slurry of cathode (positive side) and anode (negative side) electrodes according to the scheme and recipe of the polymer battery model.

2. Coating

Paste is applied to a metal foil (aluminum for cathode, copper for anode). This creates the desired positive and negative plates

3. Cutting

Cut the dried electrode plates to the exact length and width required for the battery cell.

4. Winding

The cathode, anode and diaphragm are wound together. Forms the internal structure of the cell.

5. Injection of electrolyte

Inject electrolyte into the encapsulated cell to allow lithium ions to travel between the positive and negative plates.

6. Sealing & Formation

Encapsulate the cell with an aluminum-plastic film casing to prevent the electrolyte from being exposed. Activate the internal chemical material by charging and discharging.

7. Aging and Testing

Final test of capacity, voltage and overall performance through high and normal temperature aging tests.

Our li-polymer battery production process

FAQs for lithium-polymer batteries

We can provide samples within 1 week.

It will take 20~25 days for bulk battery order.

We can provide you UL1642, IEC62133, CB, UN38.3 and MSDS as what we have.