24V 200Ah LiFePo4 Battery

25.6V 200Ah Lithium Iron Phosphate Battery (LiFePO4) is an efficient, safe and long-life lithium ion battery. It is used in various portable devices.

24V 200Ah Battery Specs

-

Work Voltage Range 21.6~29.2V

-

Nominal Voltage 25.6V

-

Nominal Capacity 200Ah

-

Rated Energy 5120Wh

-

Max Discharge Power 2560W

-

Standard Charge Current 40A

-

Recommend Charge Current ≤80A

-

Max Charge Current 100A

-

Recommend Discharge Current ≤100A

-

Max Continue Discharge Current 100A

-

Peak Discharge Current (10S) 200A

-

Resistance ≤15mΩ

-

Lifespan (25℃,0.5C,80%DOD) >6000

-

Waterproof IP65

-

Weight 42Kg

-

Size (Length * Width * Thick) 522*240*218mm

Hongyitai Batery Charging Curve

24V 200Ah lithium battery charging curve

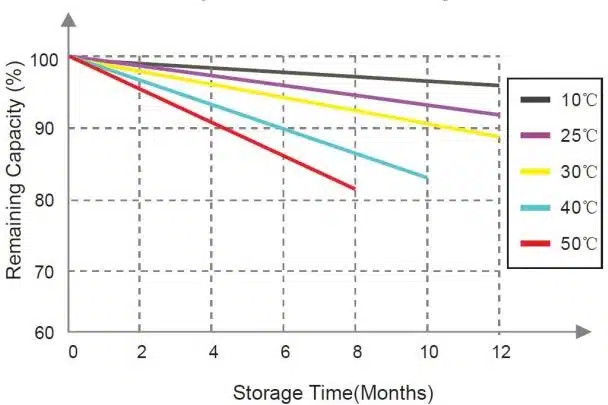

On the left is different temperature self discharge curve for 24V 200Ah lithium battery.

Main applicates for Hongyitai 25.6V 200Ah lifepo4 battery

Marine system: trolling motors for boats and kayaks, general marine power applications.

Recreational vehicles (RVs) and camping: RV battery and camping power supply.

Renewable energy: wind & solar energy storage systems, off-grid energy storage.

Low speed vehicle: Electric scooters, motorcycle, motorcycle floor cleaning machines and AGVs.

Industrial backup power: home and commercial emergency backup power & UPS.

How we make 24V 200Ah lithium battery

- Matching set of high quality LiFePO4 cells. For a 24V 200Ah lithium ion battery, we will need 8 cells in series, each with a nominal voltage of 3.2V and a capacity of 25Ah.

- Series the cells in series positively to each other to achieve a nominal voltage of 25.6V. Connect the batteries using nickel strips and a spot welder.

- Install a battery management system (PCM) to prevent overcharging, over-discharging and short circuit protection. Select a BMS with a nominal voltage of 25.6V and a continuous current of at least 100A.

- Solder the protection plate in the P+,P- position.

- Sheet metal enclosure to house the battery and BMS. cells and batteries need to be insulated.

- Install terminal connectors, fuses and any monitoring displays.

- Perform initial charge/discharge and testing to verify proper operation and capacity.

Lithium-ion battery production process

#1 Cell Selection

Select the number of 18650 cells or LiFePO4 cells we need. Ensure they works fine.

#2 Battery Sorting

Make sure that the capacity, voltage, and internal resistance of the selected cells are consistent.

#3 Arrangement & Assembly

Combine the required battery modules in a series-parallel manner.

#4 Spot Welding

The positive and negative terminals of the battery are connected via nickel tabs to form the desired capacity or voltage.

#5 Mounting Protection Board

Connect the protection board on the battery pack to ensure that its overcharge, overdischarge and short circuit protection functions properly.

#6 Packaging & Aging

Wrap the battery pack in a PVC or metal casing while charging and discharging to activate the battery pack performance.

Get in touch

Get the 24V 200Ah Lifepo4 battery quote today

We will get back to you within 1 working day.