250mAh 3.7v polymer li ion battery

Polymer battery 652025 3.7V 250mAh is a lightweight and durable rechargeable power source for small electronic products. We can provide UL1642, UN38.3, IEC62133, MSDS certificates.

- UL1642

- IEC62133

- UN38.3

- MSDS

652025 3.7V 250mAh Battery Specs

-

Charging Voltage 4.2V

-

Nominal Voltage 3.7V

-

Nominal Capacity 250mAh

-

Discharge Cut-off Voltage 3V

-

Charge Current 125mA

-

Max Charge Current 250mA

-

Discharge Current 125mA

-

Max Discharge Current 750mA

-

Operatingt Tmperature -20~60℃

-

Dimension 6.5*20*37mm

-

Weight 5g

-

Lifespan 500

-

PCM Yes

-

Customization Yes

Hongyitai Polymer Battery Factory

Li-polymer battery 3.7V 652025 250mAh 0.925Wh with protection circuit

We offer high quality polymer batteries with built-in protection boards against overcharge, overdischarge and short circuit protection. Its need to be charged with constant current constant voltage, constant voltage charger. Suitable for a variety of electronic devices that require a 3.7V power supply.

The charging and discharging current can be produced according to customer’s needs, such as 1.0C and 3.0C discharge rate. Besides the model 652025, we also have many models of 250mAh batteries.

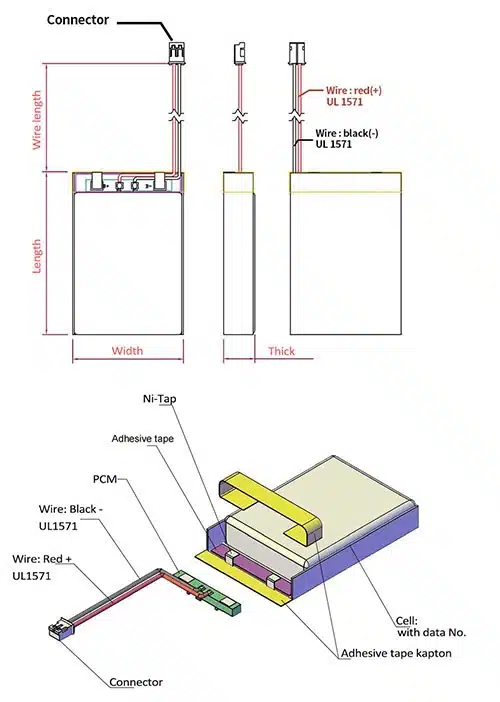

On the right is a sketch of our polymer batteries. You can clearly see the cells, protective plates, wires, terminals, insulation position, and spray code. Of course, each battery has its own unique battery information. Feel free to send us to custom your own lithium polymer battery model.

China lithium polymer battery

Li-polymer battery charge & discharge curve

Polymer Battery Curve (Time — Cpacity && Specific capacity)

Polymer Battery Curve (Time — Voltage && Current)

Cycle No. – Charge discharge efficiency

Cycle No. – Charging Capacity & Discharge Capacity & Charging Specific Capacity & Discharge

Lithium polymer battery component

Li-polymer battery connector models

Common wire gauge sizes for polymer batteries include.

16AWG (1.31mm²)

18AWG (0.82mm²)

20AWG (0.52mm²)

Commonly used terminal types for polymer batteries:

JST-XH

JST-EH

XT30

XT60

EC3

IC5

Molex 5264 Series

Molex 5268 Series

Molex 5282 Series

Molex 5264 Mini-Fit Jr.

Our li-polymer battery production process

The following is a simplified description of our lithium polymer battery manufacturing process:

1. Mixing

Make a slurry of cathode (positive side) and anode (negative side) electrodes according to the scheme and recipe of the polymer battery model.

2. Coating

Paste is applied to a metal foil (aluminum for cathode, copper for anode). This creates the desired positive and negative plates

3. Cutting

Cut the dried electrode plates to the exact length and width required for the battery cell.

4. Winding

The cathode, anode and diaphragm are wound together. Forms the internal structure of the cell.

5. Injection of electrolyte

Inject electrolyte into the encapsulated cell to allow lithium ions to travel between the positive and negative plates.

6. Sealing & Formation

Encapsulate the cell with an aluminum-plastic film casing to prevent the electrolyte from being exposed. Activate the internal chemical material by charging and discharging.

7. Aging and Testing

Final test of capacity, voltage and overall performance through high and normal temperature aging tests.

Get Started

Get 652025 3.7V 250mAh pouch battery quote today

We will evaluate your project and get back to you within 1 working day.