3.7V Li-Polymer Battery

3.7V polymer batteries are the most common and widely used type of battery. Here are its basic characteristics:

- Nominal voltage: 3.7V

- Charging voltage: 4.2V

- Discharge cut-off voltage: 3V

Based on the type of positive electrode material, they can be categorized into: lithium cobalt oxide batteries, ternary batteries, and lithium manganese oxide batteries.

In addition to 3.7V polymer batteries, there are also 3.8V high-voltage polymer batteries.

Single Battery

3.7V lipo battery always single battery unit.

High Energy Density

up to 500Wh/L ~ 620Wh/L.

Long Life Cycle

more than 500 charge & discharge cycles.

Wide Work Range

-20 ~ 60℃ working temperature range.

3.7V Polymer Battery Products

With over 200 models and capacities ranging from 50mAh to 5000mAh, our lithium polymer batteries are highly customizable to meet your specific needs.

Our 3.7V LiPo batteries are known for their consistency, allowing us to create custom battery packs in various configurations (2S, 3S, 4S) to power your devices.

- 3.7V Lipo Battery

551430 3.7V 180mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 180mAh

Rated energy: 0.666Wh

Thickness: ≤5.5mm

Widness: ≤14.0mm

Length: ≤30.0mm

Internal resistance: ≤150mΩ

502025 3.7V 200mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 200mAh

Rated energy: 0.74Wh

Thickness: ≤5.0mm

Widness: ≤20.0mm

Length: ≤25.0mm

Internal resistance: ≤120mΩ

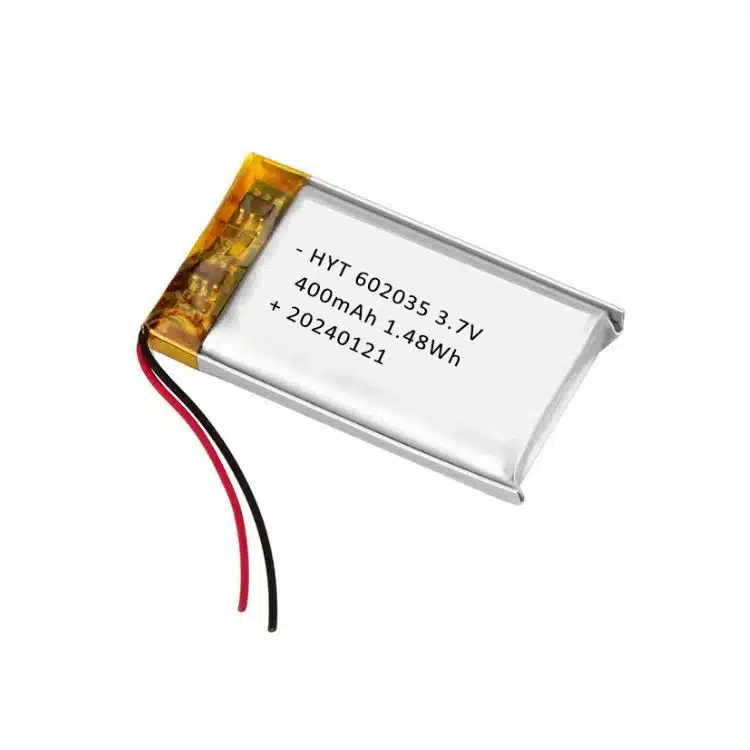

602035 3.7V 400mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 400mAh

Rated energy: 1.48Wh

Thickness: ≤6.0mm

Widness: ≤20.0mm

Length: ≤35.0mm

Internal resistance: ≤100mΩ

503035 3.7V 550mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 550mAh

Rated energy: 2.035Wh

Thickness: ≤5.0mm

Widness: ≤30.0mm

Length: ≤35.0mm

Internal resistance: ≤80mΩ

603035 3.7V 600mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 600mAh

Rated energy: 2.22Wh

Thickness: ≤6.0mm

Widness: ≤30.0mm

Length: ≤35.0mm

Internal resistance: ≤75mΩ

603048 3.7V 950mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 950mAh

Rated energy: 3.515Wh

Thickness: ≤6.0mm

Widness: ≤30.0mm

Length: ≤48.0mm

Internal resistance: ≤60mΩ

102050 3.7V 1000mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 1000mAh

Rated energy: 3.7Wh

Thickness: ≤10.0mm

Widness: ≤20.0mm

Length: ≤50.0mm

Internal resistance: ≤70mΩ

103040 3.7V 1200mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 1200mAh

Rated energy: 4.44Wh

Thickness: ≤10.0mm

Widness: ≤30.0mm

Length: ≤40.0mm

Internal resistance: ≤60mΩ

602025 3.7V 250mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 250mAh

Rated energy: 0.925Wh

Thickness: ≤6.0mm

Widness: ≤20.0mm

Length: ≤25.0mm

Internal resistance: ≤120mΩ

802540 3.7V 850mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 850mAh

Rated energy: 3.145Wh

Thickness: ≤8.0mm

Widness: ≤25.0mm

Length: ≤40.0mm

Internal resistance: ≤70mΩ

605080 3.7V 3000mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 3000mAh

Rated energy: 11.1Wh

Thickness: ≤6.0mm

Widness: ≤50.0mm

Length: ≤80.0mm

Internal resistance: ≤60mΩ

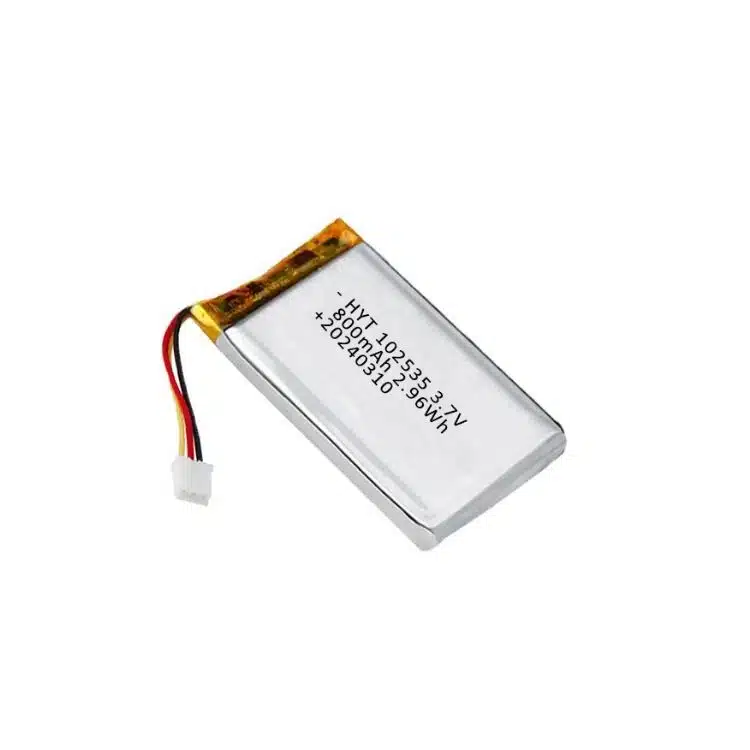

102535 3.7V 800mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 800mAh

Rated energy: 2.96Wh

Thickness: ≤10.0mm

Widness: ≤25.0mm

Length: ≤35.0mm

Internal resistance: ≤70mΩ

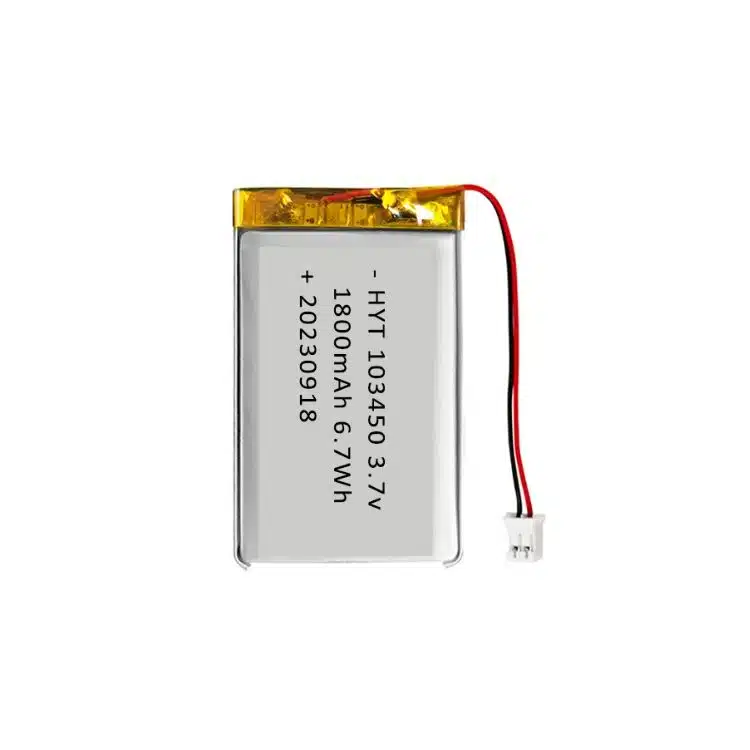

103450 3.7V 1800mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 1800mAh

Rated energy: 6.66Wh

Thickness: ≤10.0mm

Widness: ≤34.0mm

Length: ≤50.0mm

Internal resistance: ≤60mΩ

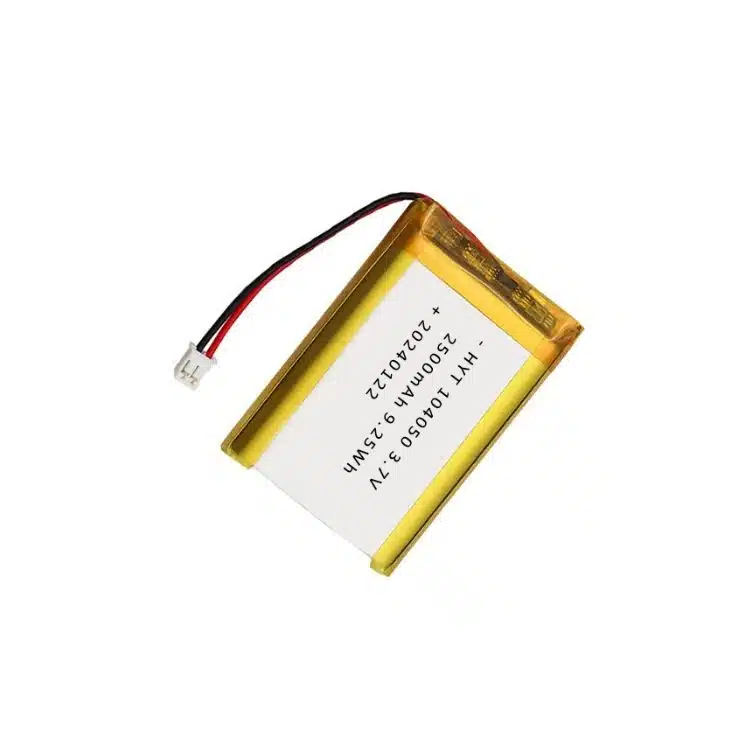

104050 3.7V 2500mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2500mAh

Rated energy: 9.25Wh

Thickness: ≤10.0mm

Widness: ≤40.0mm

Length: ≤50.0mm

Internal resistance: ≤60mΩ

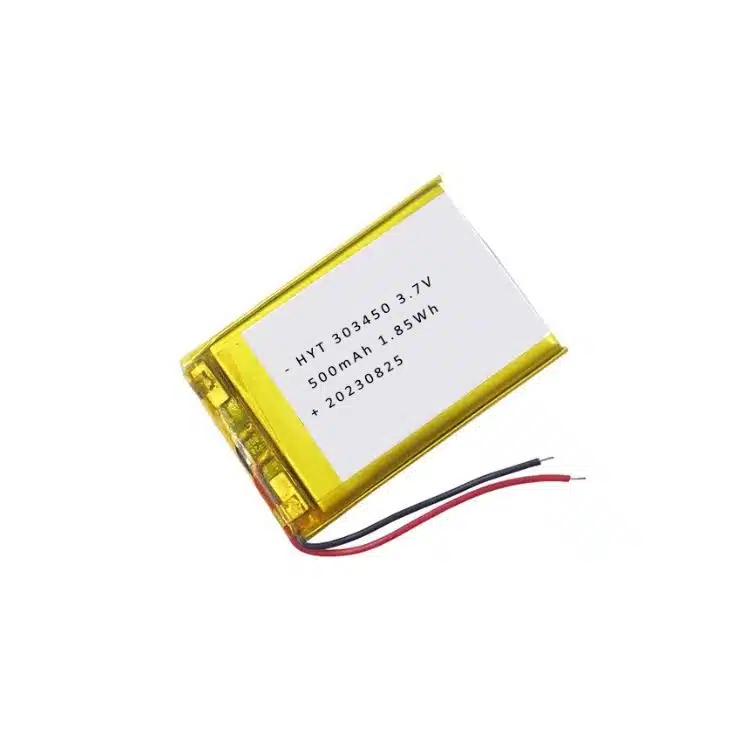

303450 3.7V 500mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 500mAh

Rated energy: 1.85Wh

Thickness: ≤3.0mm

Widness: ≤34.0mm

Length: ≤50.0mm

Internal resistance: ≤80mΩ

505080 3.7V 2000mAh Battery

Nominal voltage: 3.7V

Nominal capacity: 2000mAh

Rated energy: 7.4Wh

Thickness: ≤5.0mm

Widness: ≤50.0mm

Length: ≤80.0mm

Internal resistance: ≤50mΩ

3.7V Battery Main Application

Lithium polymer cells are suitable for wearable devices, smart sensors, Industrial & security camera, IoT devices, GPS tracking system, medical devices, and smart home systems.

Pet Tracking

A good choice for pet tracking device due to its lightweight and high energy density.

3.7V Lipo Battery Connectors

Connector Types

We offer a variety of connectors for our 3.7V LiPo batteries, including:

- Molex: 51021, 51004, 51005, 5264, 2510

- XH: XH-2P

- PH: PH-2P SMP, SYP

- JST: 2P metal space 1.5mm, 2.0mm, 2.54mm, and JST-3P

Connector Configuration

- Typically, we provide male connectors. Customers are responsible for installing the corresponding female connectors onto their main boards.

- To ensure proper connection, it is essential that the connectors match.

Positive and Negative Terminal Definition:

- By default, we define the positive and negative terminals as follows: When the battery’s metal tab is facing upwards, the red wire is on the left, and the black wire is on the right. This configuration is considered the “positive” orientation.

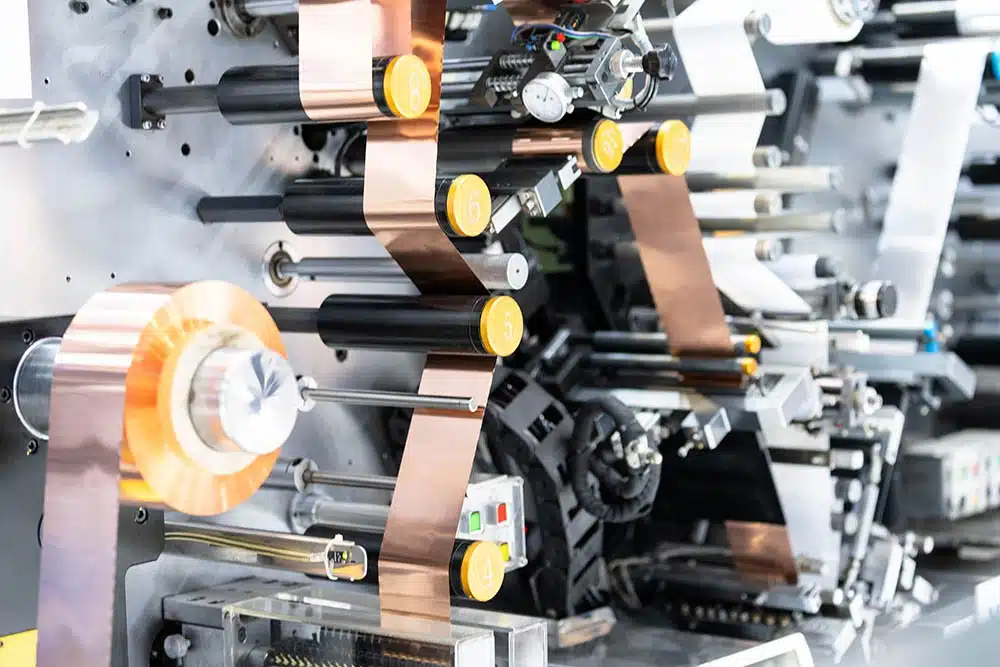

How we produce 3.7v lipo battery

1. Electrode Production

- Mixing: Active materials (like lithium cobalt oxide for the positive electrode and graphite for the negative electrode) are mixed with a binder and solvent to create a paste.

- Coating: The paste is spread onto thin metal foil (aluminum for the positive electrode, copper for the negative electrode) that will collect the current.

- Drying: The coated foil is dried to remove the solvent, leaving behind a solid layer of active material.

- Cutting: The dried electrode is cut into precise pieces to ensure consistent thickness and density for better battery performance.

2. Cell Assembly

- Stacking/Rolling: The prepared electrodes are cut to size and stacked or rolled with a separator. The separator is a thin, porous membrane that allows lithium ions to pass through but prevents electrons.

- Electrolyte Filling: The assembled cell is filled with electrolyte, which is a lithium salt dissolved in an organic solvent. This electrolyte allows lithium ions to move between the electrodes during charging and discharging.

3. Sealing

- Encapsulation: The filled cell is sealed in a pouch or metal can to prevent leaks and contamination. Heat sealing or welding is used to create a strong enclosure.

4. Formation and Aging

- Formation: The packaged cell undergoes an initial charge-discharge cycle under controlled conditions. This step helps stabilize the battery’s performance and capacity.

- Aging: The battery is stored for a period and subjected to occasional charge-discharge cycles to ensure long-term reliability. This process helps identify any early failures.

3.7V li-polymer battery pack listing

As a professional lithium battery manufacturing plant in China, our 3.7V polymer Li-ion batteries can be tailored to various applications. Whether you require low-temperature, high-temperature, or high-discharge rate batteries, we can meet your specific needs.

Please provide your battery requirements and intended use cases. We offer rapid prototyping to bring your product’s power supply to life.

- 3.7v lithium polymer battery

Model | Voltage (V) | Capacity (mAh) | Dimension (Thick*Width*Length) (mm) | Lifespan (25℃,0.5C,80%DOD) | Weight (Kg) | Protection Function | Know More |

|---|---|---|---|---|---|---|---|

HYT551430 | 3.7 | 180 | 5.5*14*30 | >500 | 4 | Yes | |

HYT502025 | 3.7 | 200 | 5*20*25 | >500 | 4 | Yes | |

HYT602035 | 3.7 | 400 | 6*20*35 | >500 | 8 | Yes | |

HYT603035 | 3.7 | 600 | 6*30*35 | >500 | 12 | Yes | |

HYT603048 | 3.7 | 950 | 6*30*48 | >500 | 17 | Yes | |

HYT102050 | 3.7 | 1000 | 10*20*50 | >500 | 18 | Yes | |

HYT103040 | 3.7 | 1200 | 10*30*40 | >500 | 21 | Yes | |

HYT652025 | 3.7 | 250 | 6.5*20*25 | >500 | 5 | Yes | |

HYT802540 | 3.7 | 850 | 8*25*40 | >500 | 15 | Yes | |

HYT605080 | 3.7 | 3000 | 6*50*80 | >500 | 55 | Yes | |

HYT102535 | 3.7 | 800 | 10*25*35 | >500 | 13 | Yes | |

HYT103450 | 3.7 | 1800 | 10*34*50 | >500 | 40 | Yes | |

HYT104050 | 3.7 | 2500 | 10*40*50 | >500 | 51 | Yes | |

HYT303450 | 3.7 | 500 | 3*34*50 | >500 | 10 | Yes | |

HYT452530 | 3.7 | 300 | 4.5*25*30 | >500 | 6 | Yes | |

HYT503040 | 3.7 | 600 | 5*30*40 | >500 | 8 | Yes | |

HYT603450 | 3.7 | 1100 | 6*34*50 | >500 | 20 | Yes | |

HYT371168 | 3.7 | 220 | 3.7*11*68 | >500 | 4 | Yes | |

HYT551035 | 3.7 | 150 | 5.5*10*35 | >500 | 3 | Yes | |

HYT453535 | 3.7 | 500 | 4.5*35*35 | >500 | 10 | Yes | |

HYT505080 | 3.7 | 2000 | 5*50*80 | >500 | 46 | Yes | |

HYT501030 | 3.7 | 100 | 5*10*30 | >500 | 2.5 | Yes | |

HYT452535 | 3.7 | 350 | 4.5*25*35 | >500 | 7 | Yes | |

HYT555368 | 3.7 | 2500 | 5.5*53*68 | >500 | 50 | Yes |

3.7V Li-polymer Battery Factory

- Minimum Order Quantity: 1,000 pieces per model.

- All orders come with the necessary certificates.

- Flexible in capacity, size, shape for prototypes and orders.

Factors to consider when choosing a 3.7V lithium polymer battery charger

When selecting a charger for your 3.7V lithium polymer battery, several key factors should be considered:

1. Charging Current:

- Choose a charging current that matches the battery’s capacity. Generally, the charging current should be 0.5C to 1C of the battery’s capacity. For example, a 500mAh battery should be charged at 250mA to 500mA.

2. Termination Voltage:

- The termination voltage should be between 4.2V and 4.28V. A voltage that is too low will result in an undercharged battery, while a voltage that is too high can damage the battery.

3. Connector Type:

- In addition to battery-specific connectors like JST, Molex, and PH, many chargers use USB-A or USB-C connections to charge devices.

- Ensure that the charger’s connector matches the battery’s connector. Common types include JST, Micro JST, and PH2.0.

4. Protection Features:

- The charger should have overcharge, over-discharge, and overcurrent protection features.

All about charging 3.7v lipo battery

1. Using a Dedicated Charger

Choose a charger specifically designed for 3.7V lithium batteries. Do not use chargers designed for other voltages. If you’re unsure about a specific charger, please contact us for confirmation.

2. Charging Voltage:

The charging voltage should be controlled between 4.2V and 4.28V. Do not exceed this voltage.

3. Charging Current:

Generally, the charging current should be 0.5C to 1C of the battery’s capacity. For example, a 1000mAh battery should be charged at 500mA to 1000mA.

4. Charging Termination Condition:

Charging should stop when the battery voltage reaches 4.2V and the charging current drops to around 0.02C of the set value.

5. Charging Environment:

Charge the battery at room temperature. Avoid high or low temperature environments.

Why select Hongyitai as lithium ion polymer battery supplier

- 10 Years Experience: Over 10 years working experience in polymer battery field.

- Free Samples: Provide 7 days free samples freely.

- Certified: Provide UL1642, IEC62133, UN38.3, MSDS, CE certificates as it is ready.

- Full Models Available: Produce no matter which li-polymer battery you want.

- Tech Support: Before production, our engineer team will guide and evaluate your battery requirements.

FAQs for battery li polymer 3.7V

"To charge a 3.7V lithium polymer battery, connect it to a USB port or power adapter using a dedicated charger. Ensure that the charging voltage is set to 4.2V and the charging current is between 0.5C and 1C of the battery's capacity. Charging should terminate when the current drops to approximately 0.02C.

Yes, lithium-ion batteries can typically be used as a replacement for lithium polymer batteries since they both have a nominal voltage of 3.7V. However, it's crucial to ensure that the new battery's capacity, discharge rate, and physical dimensions are compatible with the original. Additionally, the charger's voltage and current settings must be suitable for the new battery. Be sure to verify that the new battery fits within the device's battery compartment.

To determine if a lithium polymer battery is damaged, you can measure its voltage and internal resistance using a multimeter. Additionally, check if the battery charges normally, if its capacity has significantly decreased, and if it shows any signs of swelling or leakage.

While uncommon, lithium polymer (LiPo) batteries do pose a fire risk when not in use. Potential causes include battery damage, overcharging, or improper storage conditions. To mitigate these risks, consider using batteries with metal or ABS casings, storing them at around 50% state of charge, and keeping them in a cool, dry place. Regularly inspect batteries for signs of damage such as swelling, deformation, or leakage, and address any issues promptly.

While LiPo battery fires are relatively infrequent, they do pose a potential risk. Adhering to our specifications for appropriate charging and storage practices can significantly reduce the likelihood of such incidents. However, due to factors such as physical damage, manufacturing defects, overcharging, or mishandling, LiPo batteries may still ignite under certain circumstances.