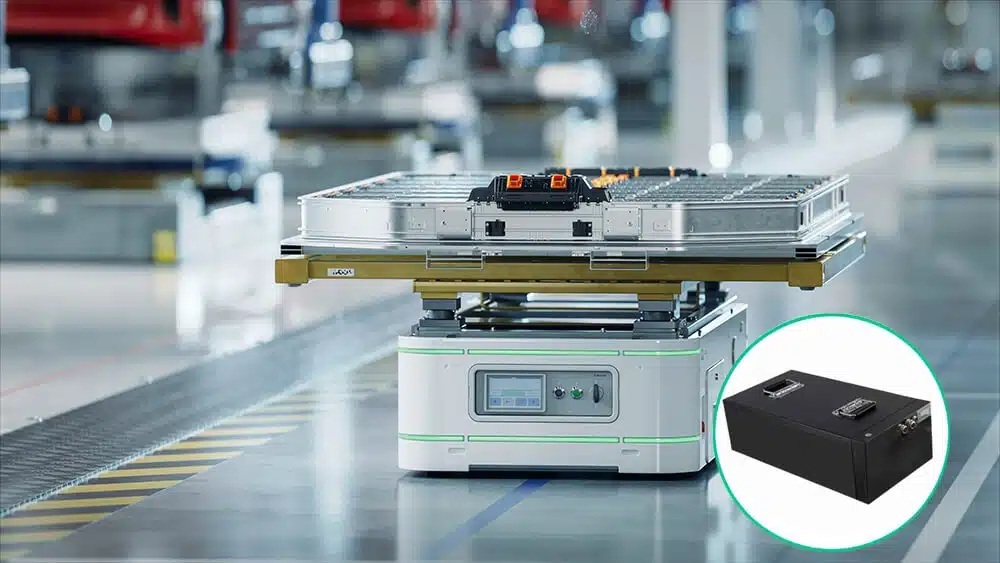

AGV Lithium Battery

AGV batteries serve as the power source for electric transportation equipment. There are two primary types of batteries: lead-acid batteries and lithium iron phosphate batteries. Based on the power requirements of the AGV, common voltages include 12V, 24V, and 48V.

AGV batteries find widespread application in various industries, such as modern production workshops, warehouses, healthcare facilities, and electronics manufacturing. Their primary function is to enable unified dispatching of ground control systems and facilitate automated material transportation.

In addition to high energy density, AGV batteries must also ensure stable power output to guarantee the efficiency and reliability of the AGV system. We are a lithium battery manufacturing factory. We can customize AGV batteries to meet your specific needs.

High Energy Density

LFP batteries offer a high energy density, reducing the need for frequent charging.

Long Cycle Life

With over 3000 cycles, LFP batteries provide long-term economic benefits.

Low Maintenance

Unlike lead-acid batteries, LFP batteries require minimal maintenance, eliminating the need for tasks such as adding water.

Flexibility and Adaptability

LFP batteries support various series and parallel combinations, making them adaptable to different application requirements.

agv battery pack product

An Automated Guided Vehicle (AGV), also known as a self-guided vehicle, is a material handling system or loading vehicle that operates without human intervention in warehouses, modern workshops, or manufacturing facilities. AGVs are designed to replace manual forklifts, enabling 24/7 operation and precise, error-free transportation to designated locations.

As you know, the AGV battery is the heart of the AGV system. It plays a crucial role in AGV operations. AGV batteries typically come in voltages of 12V, 24V, 36V, and 48V. Equipped with intelligent management systems, they ensure safety, longevity, and stable output.

- AGV Lithium Battery

36V 50Ah LiFePo4 Battery

Nominal voltage: 38.4V

Nominal capacity: 50Ah

Rated energy: 1920Wh

Recommend charge current: ≤25A

Peak discharge current: 100A

Internal resistance: ≤30mΩ

36V 100Ah LiFePo4 Battery

Nominal voltage: 38.4V

Nominal capacity: 100Ah

Rated energy: 3840Wh

Recommend charge current: ≤50A

Peak discharge current: 200A

Internal resistance: ≤25mΩ

48V 100Ah LiFePo4 Battery

Nominal voltage: 51.2V

Nominal capacity: 100Ah

Rated energy: 5120Wh

Recommend charge current: ≤50A

Peak discharge current: 200A

Internal resistance: ≤20mΩ

48V 50Ah LiFePo4 Battery

Nominal voltage: 51.2V

Nominal capacity: 50Ah

Rated energy: 2560Wh

Recommend charge current: ≤25A

Peak discharge current: 100A

Internal resistance: ≤30mΩ

48V 60Ah LiFePo4 Battery

Nominal voltage: 51.2V

Nominal capacity: 60Ah

Rated energy: 3072Wh

Recommend charge current: ≤30A

Peak discharge current: 100A

Internal resistance: ≤30mΩ

How does AGV battery perform in different working environments

The performance of AGV batteries in different working environments is influenced by various factors, including ambient temperature, humidity, and battery type. Here are some key points:

Cold Environments: In low-temperature conditions, lithium iron phosphate (LFP) batteries generally outperform lead-acid batteries. While lithium batteries can maintain a relatively good discharge capacity in cold environments, their charging and discharging performance decreases significantly compared to normal temperature conditions.

High-Temperature Environments: Lead-acid batteries typically perform better at higher temperatures, providing stable power support. However, prolonged exposure to high temperatures can shorten their cycle life.

Indoor Environments: In indoor environments, the performance of AGV batteries is generally more stable. This is the most common operating environment.

Humid Environments: In humid environments, the waterproof and moisture-proof design of the battery is crucial. Lithium batteries often require a IP65 waterproof metal casing to prevent water from entering and damaging the battery.

In conclusion, the performance of AGV batteries varies in different working environments. Choosing the right battery type and design is essential to ensure the efficient operation of the AGV.

AGV Battery Charger Type

AGV battery chargers are devices designed to recharge the batteries of Automated Guided Vehicles (AGVs). There are several types and features to consider:

Wireless Chargers:

- Models like the LYC500 are specifically designed for AGVs and other robots, offering a convenient charging solution for environments that require frequent charging.

- Models like the LYC500 are specifically designed for AGVs and other robots, offering a convenient charging solution for environments that require frequent charging.

Lead-Acid and Lithium Battery Chargers:

- A wide range of chargers are available for both lead-acid and lithium batteries. For example, a 48V 7A charger can be used for both types of batteries. When selecting a charger, ensure that the voltage matches the battery and that the charging current is approximately 30% of the battery pack’s capacity.

- A wide range of chargers are available for both lead-acid and lithium batteries. For example, a 48V 7A charger can be used for both types of batteries. When selecting a charger, ensure that the voltage matches the battery and that the charging current is approximately 30% of the battery pack’s capacity.

High-Power Chargers:

- Chargers like the 58.8V 25A model are suitable for 14S 48V and 52V lithium batteries, providing high charging efficiency and ideal for high-power AGVs.

- Chargers like the 58.8V 25A model are suitable for 14S 48V and 52V lithium batteries, providing high charging efficiency and ideal for high-power AGVs.

To ensure you purchase the right charger, please contact us for confirmation or let us recommend a suitable AGV battery.

Why choose us as AGV battery manufacturer

Selecting the right AGV battery supplier is crucial for ensuring optimal performance and reliability of your automated guided vehicles. Here are compelling reasons to partner with us:

Cutting-Edge Battery Technology: We specialize in advanced lithium-ion and lithium iron phosphate battery solutions that offer higher energy density, extended cycle life, and rapid charging capabilities. These technologies significantly enhance AGV efficiency and productivity, enabling longer operation times and reduced downtime.

Tailored Solutions: Our engineering team excels at designing customized battery packs optimized for your specific operational needs. We focus on maximizing energy storage and integrating intelligent Battery Management Systems (BMS) for fast charging and efficient energy utilization, ensuring seamless operation of your AGVs in demanding environments.

Uncompromising Reliability and Safety: Our premium batteries feature a robust multi-cell design that can withstand the rigors of industrial applications, guaranteeing safety and reliability. Equipped with comprehensive safety mechanisms, including overcharge and over-discharge protection, our batteries maintain performance under various conditions, minimizing the risk of battery failures.

Exceptional Value: While the initial investment in AGV battery technology may seem substantial, our products are designed for long-term use, providing a strong return on investment. With an average lifespan of 8 years, lithium batteries offer a superior cost-benefit ratio compared to lead-acid batteries.

FAQs for batteries for AGV

The operating time of an AGV battery is typically between 8 to 14 hours, depending on the vehicle type, load size, and operating environment. Compared to lead-acid batteries, lithium iron phosphate batteries generally have shorter charging times and a cycle life of 3000 times.

AGV lithium batteries primarily come in four voltages: 12V, 24V, 36V, and 48V. The corresponding optimal voltage ranges are 12V-14.6V, 25.6V-29.2V, 38.4V-43.8V, and 48V-54.7V, respectively.

To measure the voltage, use a multimeter. Connect the positive probe to the positive terminal of the battery and the negative probe to the negative terminal. Ensure that the multimeter is set to the appropriate voltage range.