From the mobile phones and power tools we use every day to electric cars and large energy storage, battery packs are indispensable. It is not a simple pair of batteries together, but a complex system engineering, which must include a smart management unit (BMS) for control and protection, a structural design to ensure stability, and heat dissipation. The design of this li ion battery pack directly determines its safety, performance, life and cost. This article guides a clear and structured framework.

Table of Contents

ToggleBattery pack core components and its functions

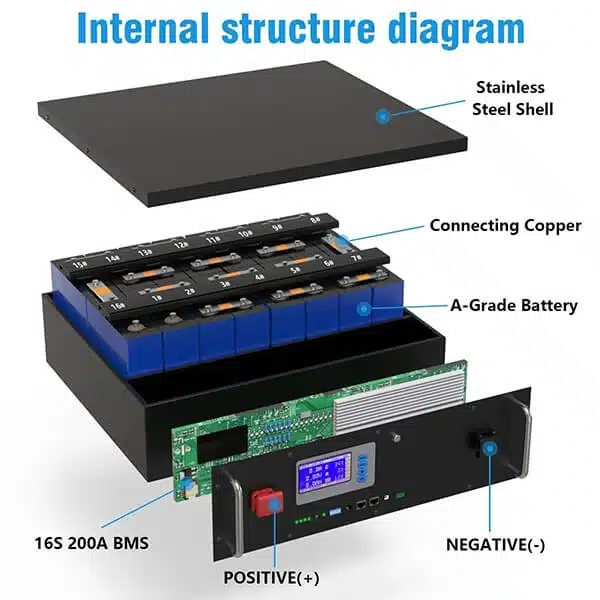

In addition to the battery cells, the battery pack also has many other components such as protection boards. We will introduce them one by one according to the functional modules below.

Battery cell

The battery cell is what actually stores and releases electrical energy. We will briefly introduce several mainstream types, classified by chemical system, such as lithium iron phosphate, ternary NMC. Classified by appearance and shape, such as cylindrical, square, soft pack, etc. The battery cell directly determines the basic performance, energy density, power and cost of the battery pack.

Battery management system (BMS)

If the battery cell is the heart, then the BMS is the brain. This is an extremely critical electronic unit. Its core mission is to ensure that the battery pack works safely and efficiently and lasts as long as possible. The following are the core functions of the protection board:

Protection: Preventing dangerous situations such as overcharging, over-discharging, over-current, and overheating is the bottom line of safety.

Monitoring: Real-time monitoring of the voltage, temperature and total current of each battery cell is the basis of management.

Balance: Ensure that all battery cells keep pace with each other and do not cause overall performance degradation or shortened life due to individual differences.

Communication: Allows the battery pack to talk to your final device (such as a power tool, vehicle) or charger. Without a BMS, the battery pack is a mess, neither safe nor usable.

Electrical connection and configuration

Connecting individual cells together to form the voltage and capacity we need involves series and parallel connections, as well as the actual connection bus, wires, and connectors. This will affect the efficiency and safety of energy transmission.

Structure and housing

This is the battery pack’s outer shell. It is responsible for firmly fixing all the internal parts together and protecting them from external impact, vibration, dust, and moisture. Common outer shells include sheet metal and ABS shells, as well as the placement of various internal materials, which directly affects the durability, weight, and safety of the battery pack.

Thermal management system

Batteries generate heat when working. Temperatures that are too high or too low will affect performance, life, and even safety. Therefore, a temperature control system is needed. Common temperature control methods include passive heat dissipation (such as heat sinks) and active cooling/heating (such as liquid cooling systems, similar to car radiators). Temperature control is one of the difficulties in battery pack design.

Additional security protection

In addition to the electronic protection of the BMS, there are usually some physical fuses. For example, a fuse that will blow when the current is too large, or a valve that can safely release pressure when the internal pressure rises abnormally. These are multiple protections.

Connectors and interfaces

These are the sockets and ports that the battery pack uses to communicate with the outside world. This includes high-current interfaces for powering the device, interfaces for charging the battery, and possible signal interfaces for BMS data transmission. The reliability of these interfaces is very important.

Cell to pack battery design

You can think of this section as a detailed construction plan or roadmap for us to build the battery pack you need. It shows how we methodically go from an idea to a reliable battery pack, step by step. This structured engineering approach is critical to guaranteeing the final result.

Clear requirements. This is the starting point for all battery pack designs. Before we consider any specific parts, we must first thoroughly understand what the battery pack needs to achieve. This requires us to communicate with you in depth to confirm: voltage, capacity, power, physical size, operating environment, charge and discharge cycle requirements, budget, and safety standards or industry specifications.

Cell selection: Once the battery pack requirements are confirmed, we will carefully select the most suitable individual cells and specific models, with the goal of finding the best balance for your application between energy density, power, life, safety and cost.

Electrical design. This step is to design the protection board for the battery pack. We need to calculate how many cells need to be connected in series to achieve the target voltage, and how many cells need to be connected in parallel to achieve the target capacity. Then, we will select or specially design a matching battery management system (BMS) to manage and protect these cells. At the same time, we also need to calculate and select appropriate wires, connectors, fuses, etc. to ensure that the current can be transmitted safely and efficiently.

Structural design. This is about designing the internal skeleton and the outer shell. We need to plan the best layout of components such as cells, BMS, wiring harnesses, etc. in a limited space. We will design the shell to provide not only physical protection (anti-shock, vibration), but also meet environmental protection requirements (such as IP6 waterproof rating) and ensure that all components are firmly mounted together.

Thermal management. Batteries generate heat when they are charged and discharged. Therefore, we need to analyze how much heat will be generated under the expected operating conditions and design a corresponding heat dissipation solution. This may include simple passive heat dissipation (such as heat sinks, thermally conductive silicone) or complex active systems (such as fans, liquid cooling).

Safety analysis and integration. Safety principles are integrated throughout the design process, and we also conduct formal safety assessments. We analyze potential failure modes and their effects, which is often called FMEA (Failure Mode and Effects Analysis). We ensure that all designed safety measures can work effectively as a whole to minimize risks.

Battery pack prototyping. When the design is mature, we will start to produce battery pack samples. Then, we will put them through a series of rigorous tests, including electrical performance, thermal performance, mechanical performance, and key safety performance tests. Testing is a key link to verify whether the design is reliable and effective in the real world.

Manufacturability considerations. No matter how good a design is, it will not work if it is too complex or too costly to be mass-produced. Therefore, during the entire design process, especially in the later stages, we will focus on manufacturability design. We will consider factors such as assembly process, parts procurement, production tooling, quality control, etc.

Key design considerations and trade-offs

A common problem encountered in lithium battery pack design is that you cannot achieve the best of all indicators at the same time. This requires finding the best balance between various mutually restrictive factors. Let’s take a look at the key factors that we need to weigh:

Safety is the primary principle of lithium ion battery pack design. No factor is more important than safety. One of our core design goals is to prevent any dangerous situations from happening, especially to avoid thermal runaway.

Performance and life trade-off. Usually, the pursuit of extremely high performance (such as instantaneous high power output, fast acceleration of the device or extremely fast charging) tends to accelerate battery aging, thereby shortening its cycle life. We will optimize the design as much as possible to extend the life according to your needs while meeting the performance requirements.

The trade-off between energy density and power density. Energy density is how much electrical energy can be stored in a certain volume or weight, while power density is how quickly the energy can be released. It depends on whether you pursue durability or burst power. We need to make a choice based on whether your application values long battery life or instantaneous high power output.

Cost. This includes the cost of battery cells, protection boards, housings, thermal management solutions, certifications, etc. We need to find a reasonable balance between your desired performance, functionality, safety level and your budget.

Size and weight. To make batteries smaller and lighter, we often need to use more advanced (and potentially more expensive) cells or materials, and may require more complex thermal management designs. This is mutually constrained by cost and sometimes even certain performance indicators.

Reliability and durability. To work continuously and stably in various working environments and withstand physical shock and environmental pressure. This requires us to use high-quality components, solid structural design and sufficient testing and verification.

Regulatory compliance and certification. This is a prerequisite for meeting market access requirements. The design must comply with all relevant safety standards and regulatory requirements of your product’s target sales location, such as UN38.3, UL, CB, IEC62133 and other standards.

Summary

We have discussed the components of the battery pack, the design process, and how to make trade-offs between various core considerations. This is a relatively complex system engineering. If you want a specialist battery pack design, please contact us to give you the best solution.

FAQs:

Although the basic process of battery pack design and manufacturing may seem simple, it faces many complex challenges in practical operation. The following are key points that require special attention:

- Risk of thermal runaway: An effective thermal management system is required to prevent overheating from causing the battery pack to catch fire or explode.

- Balanced management: Inconsistencies between battery cells, such as capacity or voltage, may lead to performance degradation and even damage to the entire battery pack. The balanced function protection board can effectively avoid this risk.

- Quality control: In addition to high-quality battery cells and protective boards, it is also necessary to strictly control the quality according to the production process.

Addressing these challenges is at the core of ensuring the reliability and safety of battery packs.

Yes, building your own DIY battery pack can be more cost-effective, especially for small devices or personal projects. However, when designing high-power battery packs (such as energy storage systems), cost-effectiveness may decrease, requiring specialized production and testing equipment, and requiring professional personnel to accompany the operation.

- Improper thermal management: Overheating may lead to uncontrolled heat generation, resulting in battery damage or even accidents.

- Electrical overload: Excessive current or mismatched voltage can cause damage to internal components and shorten battery life.

- External mechanical damage: Vibration, compression, or impact may cause structural damage to the battery.

- Battery aging: As the usage time increases, the chemical properties of the battery will degrade, leading to a decrease in capacity and an increase in internal resistance.