Series connection certainly gives you the higher voltage you need, but it also presents unique charging challenges. Unlike single-cell batteries, charging a series battery pack is not as simple as plug-and-play. The difficulty lies in ensuring the balance of each battery and, crucially, charging safety.

This guide provides you with a clear and authoritative set of best practices for charging series lithium-ion batteries. By following these guidelines, you will be able to safely and efficiently charge your battery pack to maximize its performance and extend its life.

Table of Contents

ToggleWhy is charging lithium batteries in series so special

A common way to increase the voltage of batteries is to connect them in series. For example, if you connect two 3.7V lithium batteries in series, you get a 7.4V battery pack. If you connect three 3.7V lithium batteries in series, you get an 11.1V battery pack. This may seem simple, but when charging, this series structure introduces a challenge that needs to be taken seriously.

Before connecting the battery pack in series, the capacity, internal resistance, voltage, and self-discharge rate of each battery cell must be matched to ensure that the differences between each battery cell are within an acceptable range. The risks of unbalanced battery pack charging are as follows:

Risk of single-cell overcharging. A single battery is fully charged first, while other cells are not fully charged and need to be charged. This can easily cause overcharging, leading to runaway internal chemical reactions, resulting in heating, bulging, leakage, and even thermal runaway, fire, or explosion.

Single-cell over-discharge risk. During the discharge (use) process, the cell with the lowest capacity or the highest internal resistance will be the first to run out of power, and its voltage will drop below the discharge cut-off voltage (3V) first. This forces the cell to be over-discharged, causing irreversible damage, rapid capacity decay, or even permanent failure.

The overall battery pack capacity is limited by the smallest capacity cell. The effective available capacity of the entire battery pack is actually determined by the cell with the lowest capacity.

Significantly shorten the life of the battery pack. If the battery is in an unbalanced state for a long time, some cells will repeatedly experience slight overcharge or over discharge, which will accelerate the aging of the entire battery pack.

| Parameter | Acceptable Variance Range | Impact & Explanation |

|---|---|---|

| Capacity | ±5% | Significant variance can lead to overcharge/over-discharge of individual cells, reducing overall pack lifespan. |

| Internal Resistance | ±10% | Large variance leads to uneven current distribution and increased risk of uneven heating during high load/charge. |

| Voltage | ≤ 50mV | Significant initial voltage difference impacts balancing effectiveness and potentially poses safety risks. |

| Self-Discharge Rate | Within a few percent | High variance leads to charge imbalance over time (uneven SoC), impacting usable capacity (runtime/range) and lifespan. |

Key solution: battery management system

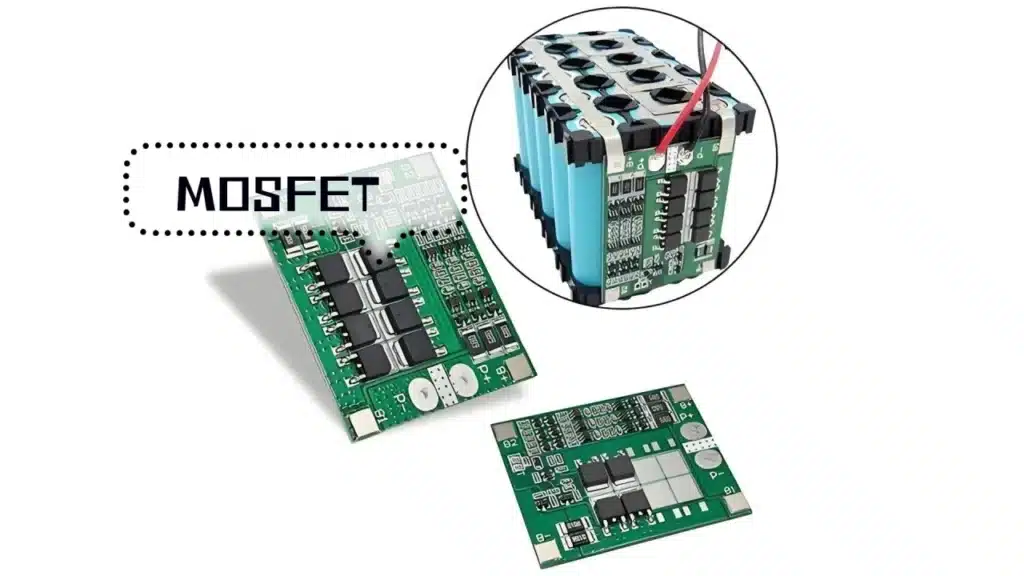

In the face of the above charging risks, the battery management system (BMS) is a universal solution. BMS is an intelligent electronic circuit board specially designed to monitor and manage rechargeable battery packs. You can think of it as the brain of the battery pack, monitoring the dynamics of the battery pack and performing key protection and management tasks.

A qualified BMS usually has one or more of the following key protection and management functions:

Single cell overcharge protection, BMS monitors the voltage of each cell in the battery pack in real time. Once the voltage of a single cell reaches the overcharge cut-off voltage (4.2V), the BMS will cut off the charging circuit.

Single cell over-discharge protection. Similarly, the BMS monitors the voltage of each battery cell. Once the voltage of a single battery cell reaches the discharge cut-off voltage (2.5V or 2.8V), the BMS will cut off the discharge circuit.

Overcurrent protection: BMS monitors the total current of the battery pack. When the charging or discharging current exceeds the set safety limit (possibly due to excessive load or charger failure), BMS disconnects the circuit to protect the battery and equipment.

Short circuit protection: In the event of an external short circuit, the current will rise instantly. The BMS can detect the current change in a very short time and quickly cut off the circuit to prevent the battery from being damaged or catching fire due to the huge current.

Temperature monitoring and protection: Many BMS are equipped with a temperature sensor (NTC). It can monitor the temperature changes of the battery pack, and when the temperature is too high or too low, the BMS will cut off charging or discharging to provide additional safety protection.

Cell Balancing: This is a very important and unique feature for series connected battery packs. It directly solves the cell inconsistency problem discussed above. The role of the balancing function is to actively or passively adjust the charge of each cell during the charging process so that their voltages tend to be consistent.

Deep understanding of cell balancing

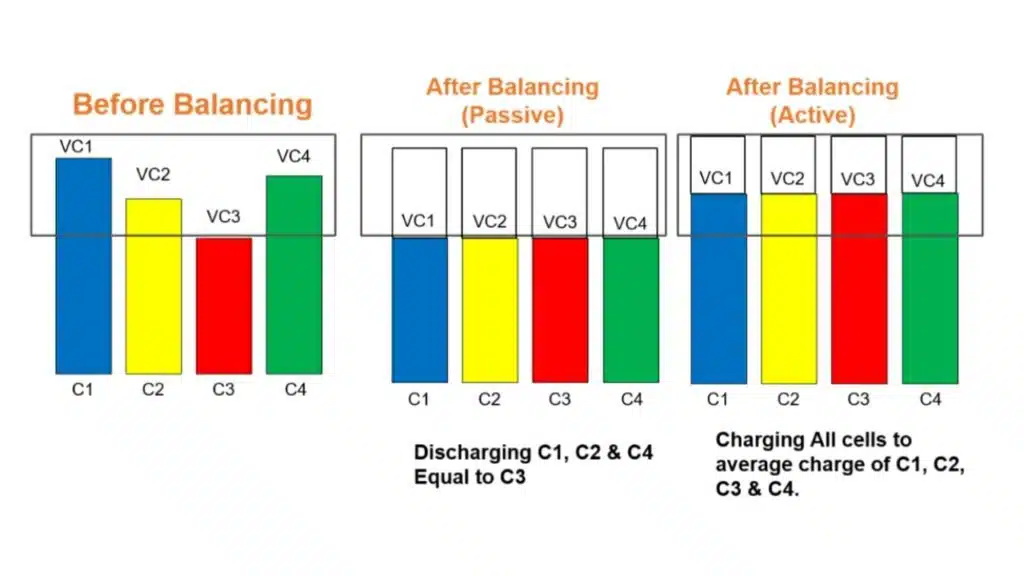

The goal of cell balancing is very clear, to ensure that at the end of charging, the voltage of all cells in the series battery pack is as close to the same as possible. Since voltage is usually closely related to the state of charge (SOC), balancing aims to bring all cells to a similar SOC.

BMS achieves cell balancing mainly through two technical paths: passive balancing and active balancing.

Passive balancing is the most common and low-cost method. When the battery pack is charging, the BMS monitors the voltage of each cell. If the voltage of a cell reaches the preset balancing start threshold (4.15V) earlier than other cells, the BMS will connect a small power resistor in parallel to this cell. The current flowing through the resistor generates heat, which consumes part of the charging energy of this cell, slowing down its voltage rise rate and giving other cells time to catch up. This process continues until all cells are fully charged.

Advantages of passive equalization: relatively simple circuit design, low cost and mature technology.

Passive balancing disadvantages: Excess energy is dissipated as heat, reducing charging efficiency. Most passive balancing is only activated when the battery is nearly full.

Active balancing is a more advanced and efficient technology. It does not simply consume the energy of high-voltage cells, but uses a special energy transfer circuit (capacitor, inductor or transformer) to transfer energy from higher-voltage cells to lower-voltage cells.

Advantages of active balancing: Energy is transferred between cells with little loss and high overall energy utilization. It can work in various states such as charging, discharging or static.

Disadvantages of active equalization: The cost of components and design is much higher than that of passive equalization solutions.

For any series-connected li-ion battery pack seeking performance, safety and long life, a BMS with effective cell balancing is absolutely essential.

Choose the right charger

In addition to a reasonable BMS, the right charger is also important. When choosing a charger, you need to pay attention to the following key parameters:

Charging voltage, the output voltage of the charger must match the total full voltage of the battery pack. A 3-series (3S) standard Li-ion battery pack (single 4.2V charging voltage) requires a charger with an output voltage of 12.6V (3 x 4.2V). A 4-series (4S) lithium iron phosphate (LiFePO4) battery pack (single charging voltage 3.65V) requires a charger with an output voltage of 14.6V (4 x 3.65V).

Chemical type matching must be clearly marked for lithium-ion batteries. Standard lithium-ion chargers usually use CC/CV (constant current/constant voltage) charging mode. Never use chargers designed for other battery types (such as lead-acid batteries, NiMH/NiCd batteries).

For current design, we generally recommend setting the charging current between 0.5C and 1C, where C refers to the capacity of the battery pack (Ah). For a 5Ah battery pack, a 0.5C charging current is 2.5A, and a 1C charging current is 5A.

The final cut-off voltage of charging and discharging is controlled by BMS.

Best practices for charging series-connected lithium batteries

Before the first charge, it is strongly recommended to measure and record the voltage of each battery cell in series before connecting the battery pack to the BMS and charging. If the voltage difference is large, it is recommended to manually charge a battery cell so that the voltage difference of all batteries does not exceed 50mV.

Strictly follow the instructions or wiring diagram of the BMS you are using to make the connections. First connect the BMS’s balanced sampling line to the corresponding node of the battery pack (starting from the total negative electrode B-, connect B1, B2… until the total positive electrode Bn). Make sure the sequence is correct and the contact is good. Then connect the total negative electrode of the battery pack to the B- of the BMS (or the negative terminal of the battery for P-/C-). Finally, connect the BMS’s output/charging terminal (P- and C-, or P- for common port) to the load or charger.

Choose a cool, dry, well-ventilated charging environment. Avoid direct sunlight or near heat sources.

Set a reasonable charging current. Generally, the charging current is 0.3C ~ 0.5C rating of the battery pack capacity. For example, for a 18650 3S2P 5Ah battery pack, the best charging current is 1.5A ~ 2.5A.

During charging, try to monitor the charging process throughout. Pay attention to the status indicator on the charger. If it becomes abnormally hot during charging, stop charging immediately.

Normal charging stops when the BMS sends a signal or the charger determines that the charging is complete. Try to avoid frequent interruptions when charging is not complete.

First disconnect the charger from the AC power source (wall outlet). Then disconnect the charger from the battery pack.

Safety first, critical don'ts

After mastering the correct charging method, it is also important to remember which behaviors are absolutely prohibited.

Do not mix mismatched equipment, and absolutely do not use a BMS or charger that does not match the string count, chemistry (Li-ion vs LiFePO4), or voltage specifications of your battery pack.

Never intentionally bypass the BMS protection circuit for the sake of convenient charging with high current.

Never attempt to charge any battery pack that appears swollen, has a broken casing, has leaked, has been severely impacted, or has any other form of physical damage.

Strictly adhere to the allowable charging temperature range specified in the battery cell and BMS specifications.

Do not leave charging unattended for long periods of time, especially if the battery pack, BMS or charger is new or has just been repaired.

Do not charge in a confined, unventilated space. Ensure that the charging area is well ventilated to help dissipate heat and prevent potential gas accumulation.

It is recommended to have appropriate fire fighting equipment available, such as a Class D metal fire extinguisher (for lithium metal), or at least plenty of dry sand.

Conclusion

To safely and effectively charge the series lithium battery pack, it is best to use a BMS and a correct charger that is precisely matched to the battery pack and has a balancing function; and strictly abide by the established safety operating procedures to avoid potential risks. We at Hongyitai specialize in customizing various lithium battery pack solutions, and warmly send emails for consultation.