When searching for a battery solution, it is crucial to understand the drawbacks of lithium-ion batteries. While this battery technology excels in energy density and lightweight, drawbacks such as safety risks, limited lifespan, and high cost may affect your decision. As a professional lithium battery manufacturer, we provide a comprehensive analysis to help you make an informed choice.

Last updated: May 2025 | Estimated reading time: 8 minutes

Table of Contents

ToggleThe core disadvantages of lithium-ion batteries

Although lithium-ion batteries are popular, they have obvious limitations and disadvantages. These problems not only affect product performance, but may also bring safety hazards and additional costs. As a leading lithium battery manufacturer in China, we analyze these shortcomings in depth to help you make a more informed choice.

Lithium-ion battery technology has made significant progress since its commercialization in the 1990s, but there are still three core issues that have not been fully resolved: safety concerns, limited lifespan, and high cost. Understanding these shortcomings is critical for battery selection, system design, and safety management, especially in electric vehicles and large-scale energy storage projects.

Safety concerns: Why lithium batteries can catch fire and explode

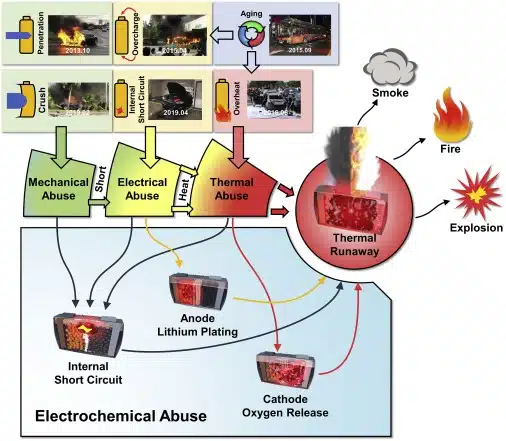

The safety risks of lithium batteries mainly come from the combination of their high energy density and flammable electrolyte. When the battery temperature is too high, it is physically impacted or an internal short circuit occurs, it may lead to thermal runaway, causing fire or even explosion. Compared with other battery technologies, the safety risks of lithium-ion batteries deserve more attention.

Positive materials such as lithium cobalt oxide in lithium batteries release oxygen at high temperatures, and the electrolyte is usually composed of carbonate organic solvents, which are extremely flammable. When the battery has an internal short circuit due to overcharge, overdischarge or production defects, the temperature will quickly rise to 200-300°C, triggering a chain reaction. According to the U.S. Consumer Product Safety Commission, lithium-ion battery-related accidents increased by 35% year-on-year from 2022 to 2024.

| Lithium Battery Type | Safety Risk Level | Thermal Runaway Temperature | Main Safety Measures | Practical Implications for You |

|---|---|---|---|---|

| Lithium Cobalt Oxide (LCO) | High | 150-200°C | Protection Circuit, Flame-retardant Housing | Requires stricter charging and discharging management |

| Lithium Iron Phosphate (LFP) | Low to Medium | 270-300°C | Battery Management System | Suitable for scenarios with high safety requirements |

| Lithium Manganese Oxide (LMO) | Medium | 200-250°C | Thermal Sensor, Fuse | Use with caution in environments with large temperature fluctuations |

| Lithium Polymer (LiPo) | Medium to High | 180-220°C | Special Packaging, Protective Case | Avoid physical damage in portable devices |

Practical safety advice for users:

- Charging environment selection: Always charge in a well-ventilated and moderately warm environment (10-30°C), away from direct sunlight.

- Device usage habits: Avoid long-term storage of fully charged batteries. The ideal storage capacity is 40-60%, which can extend the battery life by 30%.

- Charger matching: Use original or safety-certified chargers to avoid the risk of overcharging caused by inferior chargers.

- Physical protection: protect the battery from being crushed, punctured or severely impacted, especially lithium polymer batteries (disadvantages of lithium polymer battery include physical fragility)

In 2023, an electric bicycle manufacturer reduced the battery-related accident rate by 85% by replacing lithium iron phosphate batteries and optimizing the battery management system. Although the cost increased by 12%, user safety and brand trust were greatly improved.

For more information on lithium battery safety testing, please refer to our lithium battery safety testing standards and methods.

Lifespan issues: Why does your lithium battery keep failing

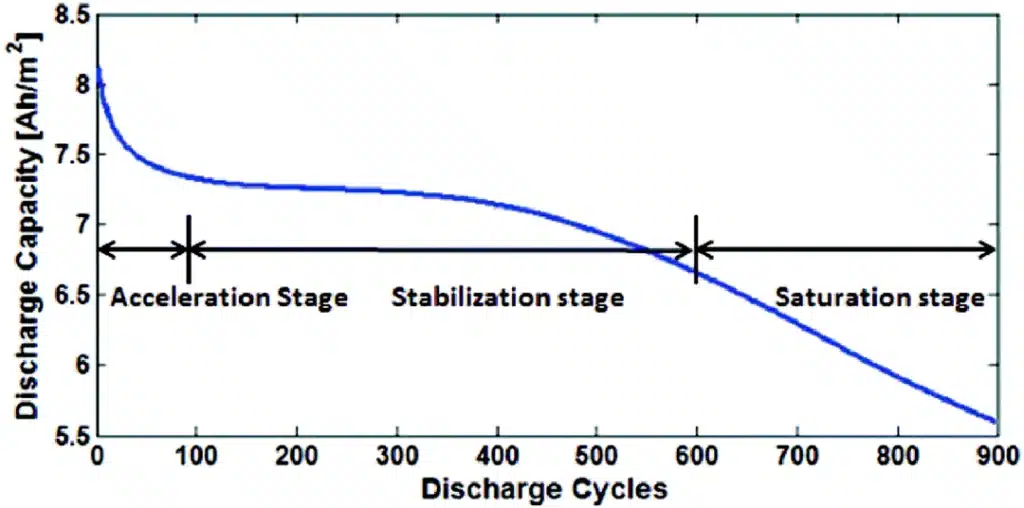

The cycle life and calendar life of lithium-ion batteries are clearly limited, and performance will typically decline significantly after 500-2000 cycles or 3-5 years. This degradation is mainly caused by electrode material aging, electrolyte decomposition and lithium ion loss, which will directly affect the equipment’s service life and replacement costs.

Battery life is one of the main disadvantages of lithium ion battery technology, especially in the field of electric vehicles. As the number of charge and discharge cycles increases, the battery capacity will show a significant decline. After 300-500 cycles, the capacity of most consumer electronic products will drop to less than 80% of the original value. In high temperature environments (above 35°C) or under frequent fast charging conditions, this attenuation rate will accelerate by 40-60%.

Comparison of lifespan of different lithium battery types

| Battery Type | Average Cycle Life | Calendar Life | Factors Affecting Lifespan | Implications for Your Application |

|---|---|---|---|---|

| Lithium Cobalt Oxide (LCO) | 500-1000 Cycles | 2-3 Years | High Temperature Sensitivity | Frequent Replacement Needed for Small Devices Like Phones |

| Lithium Iron Phosphate (LFP) | 2000-4000 Cycles | 5-8 Years | Good Tolerance to Deep Discharge | Suitable for Long-term Energy Storage and Commercial Applications |

| Lithium Manganese Oxide (LMO) | 300-700 Cycles | 2-3 Years | Rapid Degradation at High Temperatures | Shorter lifespan is one of the Lithium Manganese Dioxide Battery disadvantages |

| Nickel Manganese Cobalt (NMC) | 1000-2000 Cycles | 3-5 Years | Sensitive to Charging Voltage |

Practical strategies for extending battery life

- Avoid extreme temperatures: Use and store the battery in an environment of 10-25°C. High temperatures can shorten the battery life by more than 50%.

- Avoid deep discharge: Try not to let the battery fully discharge, it is ideal to maintain a charge range of 20%-80%.

- Use a smart charger: Use a charger with trickle charge function to avoid continuous full charging.

- Reduce fast charging: Although convenient, frequent fast charging can shorten battery life by 15-30%.

Test data from a Chinese lithium battery manufacturer showed that an electric vehicle battery pack that was limited to a charging range of 20%-80% at a constant temperature of 25°C still maintained 92% of its capacity after 6 years; while the same model battery pack that was frequently charged to 100% and deeply discharged had its capacity dropped to 78%.

High cost: Why lithium battery prices remain a barrier

The high cost of lithium-ion batteries is mainly due to raw material prices, production process complexity and safety management requirements. Although the price has dropped by about 80% in the past decade, the cost per kilowatt-hour is still 1.5-3 times higher than traditional technologies such as lead-acid, which greatly limits its application in some fields.

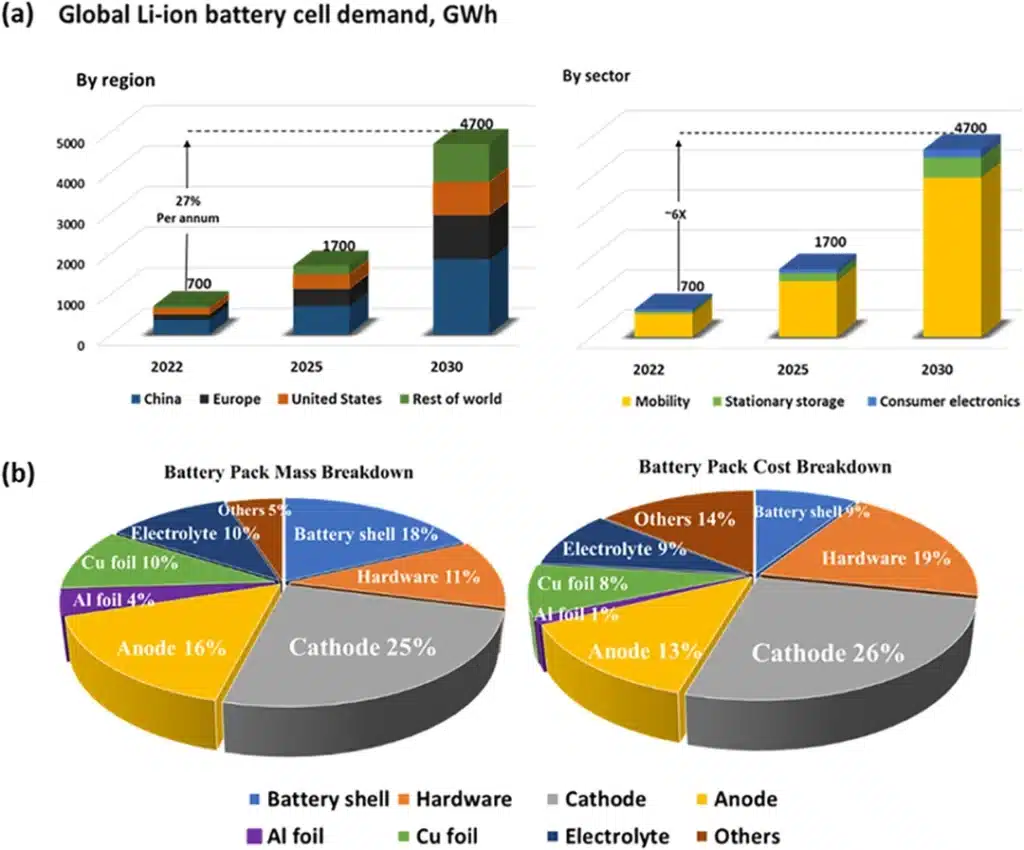

Raw materials account for about 50-70% of the cost structure of lithium batteries, among which the prices of key metals such as lithium, cobalt and nickel fluctuate greatly. Although the price of lithium carbonate has declined in 2023, it is still higher than the historical average. In addition, advanced battery management systems (BMS), precision manufacturing processes and strict safety testing also increase production costs. For large-scale energy storage projects, although the unit cost has been reduced, the initial investment is still significantly higher than traditional solutions.

Lithium battery cost structure analysis

| Cost Factor | Percentage | 2023-2025 Trend | Cost Optimization Potential | Impact on Your Purchasing Decisions |

|---|---|---|---|---|

| Raw Materials | 50-70% | Lithium Price Fluctuations, Overall Stabilization | Medium | Long-term Contracts Can Lock in Favorable Prices |

| Manufacturing Process | 15-25% | Increased Automation, Cost Reduction | High | Products from Large-Scale Manufacturers are More Cost-Effective |

| Battery Management System (BMS) | 8-15% | Technological Advancements, Improved Cost-Effectiveness | Medium | Avoid Over-Simplifying BMS to Reduce Costs |

| Research & Testing | 5-10% | Standardization, Slight Cost Reduction | Low | Choose Reputable Manufacturers with Stringent Testing for Higher Safety |

Strategies to reduce lithium battery costs

- Choose a chemical system suitable for the application scenario: Choose the appropriate battery type for different applications. For example, choosing lithium iron phosphate batteries for energy storage can reduce costs by 30-40%.

- Large-scale procurement: Bulk orders can enjoy a 5-15% price discount, and Chinese manufacturers usually offer more competitive prices.

- Full life cycle assessment: Consider the total cost over the life of the battery, not just the initial investment.

- Second-life planning: Plan the battery’s second-life path from high-demand applications to secondary applications to maximize return on investment.

An industrial park cooperated with a Chinese lithium battery manufacturer and adopted the “energy storage first, then cascade utilization” model, shortening the original planned 5-year investment recovery period to 3.2 years and reducing the total cost of ownership by 24%.

The impact of lithium battery shortcomings on various industries

The shortcomings of lithium-ion batteries have imposed different degrees of limitations and challenges on different industries. Understanding how these limitations affect your specific application scenarios can help you develop a more reasonable technical route and risk management plan. The degree of match between the limitations of lithium battery technology and your application requirements will directly determine the success of the project.

Different industries have different requirements for battery performance, from the high energy density required by electric vehicles, to the long cycle life required by large-scale energy storage systems, to the thin and light design pursued by consumer electronics products, the shortcomings of lithium batteries have different impacts in different scenarios. As the world’s largest lithium battery producer, China’s manufacturers are developing customized solutions for the pain points of various industries.

Electric vehicle industry

Lithium-ion batteries face major obstacles in electric vehicle applications, such as limited driving range, long charging time and safety risks. Although technology continues to advance, the disadvantages of lithium-ion batteries in electric vehicles are still important considerations in consumers’ purchasing decisions.

The battery pack of an electric vehicle usually accounts for 30-40% of the total vehicle cost, and its performance directly determines the practicality of the vehicle. In cold weather (-10°C), the effective range of lithium batteries may drop by 30-50%. In addition, although fast charging is convenient, it will accelerate battery aging, and the safe management of high-density battery packs is also a technical challenge. According to the 2024 Electric Vehicle Market Survey, 32% of potential consumers still regard battery life and safety as their main concerns.

| Electric Vehicle Battery Challenges | Technical Impact | Consumer Concerns (Percentage) | Industry Response Strategies | Improvement Trends by 2025 |

|---|---|---|---|---|

| Limited Driving Range | 200-600km per charge | 45% | High-Density Batteries, Lightweight Design | 15% Increase in Energy Density |

| Slow Charging Speed | Regular Charge 6-8 hours, Fast Charge 30-45 minutes | 38% | 800V Fast Charging Architecture | 40% Reduction in Charging Time |

| Poor Low-Temperature Performance | 30-50% Range Reduction in Cold Environments | 27% | Battery Preheating Systems | 25% Improvement in Low-Temperature Performance |

| Safety Risks | Collisions or Manufacturing Defects Can Cause Fires | 32% | Improved BMS, Protective Structures | 60% Reduction in Safety Incident Rate |

Large-scale energy storage

The limitations of lithium battery energy storage systems in long-term energy storage applications are mainly reflected in the short storage time and high life cycle cost. Currently, lithium battery energy storage systems are most suitable for short-term energy storage needs of 2-4 hours, and it is difficult to meet long-term energy storage requirements of more than 8 hours.

Large-scale energy storage projects have extremely high requirements for battery cycle life and safety. In grid-level applications, the self-discharge rate of lithium batteries (3-5% per month) and temperature management requirements increase the complexity and cost of operation and maintenance. According to data from the China Energy Storage Alliance in 2023, the battery replacement cost of large-scale energy storage projects accounts for about 25-35% of the total project cost, which significantly affects the long-term economic viability of the project.

| Energy Storage System Parameters | Lithium-ion Battery Performance Limitations | Impact on Projects | Optimization Measures | Technological Development Directions |

|---|---|---|---|---|

| Storage Duration | Optimal Economic Range: 2-4 Hours | Difficulty Supporting Long-Duration Needs | Hybrid Energy Storage Architecture | Long-Duration Battery Technology |

| Cycle Life | 5000-8000 Cycles (Approx. 15-20 Years with Daily Cycling) | Requires Planning for Replacement Costs | Battery Health Management System | Research on Materials to Extend Lifespan |

| Safety Management | Requires Complex BMS and Fire Suppression Systems | Increases System Costs by 20-25% | Zoned Design, Early Warning Systems | Solid-State Battery Technology |

| Initial Investment | 600-1000 RMB/kWh | Extends Payback Period to 7-10 Years | Cascade Utilization, Ancillary Services | 15-20% Cost Reduction |

Consumer electronics

The main disadvantages of lithium batteries in consumer electronics are limited use time, rapid capacity decay and safety concerns. In particular, as the functions of electronic devices increase, the contradiction between battery capacity and power consumption becomes more prominent.

Smartphones, laptops and other products usually use high-energy-density lithium batteries to meet the requirements of thin and light design, but this also brings safety risks. The capacity of batteries in consumer electronic products usually decays significantly after 1-2 years, which is manifested as a shortened battery life. The disadvantages of lithium polymer batteries are particularly prominent in consumer electronics, such as capacity decay, risk of bulging, and inability to replace them by yourself.

| Application Scenario | Typical Lithium Battery Issues | User Impact | Manufacturer Countermeasures | Your Mitigation Strategy |

|---|---|---|---|---|

| Smartphones | Significant Degradation After 1-2 Years, Difficult to Replace | Premature Device Obsolescence | Optimize System Power Consumption | Use Battery Protection Apps |

| Laptops | Accelerated Aging Due to High Temperature Usage | Restricted Usage Environment | Improved Heat Dissipation Design | Avoid Prolonged High-Load Usage |

| Wearable Devices | Small Size, Short Battery Life | Inconvenience of Frequent Charging | Ultra-Low Power Consumption Components | Select Power-Saving Mode |

| Wireless Earphones | Limited Cycle Life of Small Lithium Batteries | Shortened Usage Time After 1-2 Years | Charging Case Design | Avoid Storing in Charging Case for Extended Periods |

How to overcome these shortcomings

Strategies to address the shortcomings of lithium batteries are being developed in many ways, including material innovation, system optimization, and new battery technologies. These advances are gradually alleviating the limitations of lithium batteries and improving their practicality and safety in various application scenarios.

Lithium battery technology continues to evolve, and Chinese manufacturers have made significant progress in reducing costs and improving performance. In 2025, the lithium battery technology route will show a diversified development trend, from improving existing battery chemical systems to developing new energy storage technologies, providing more suitable solutions for different application needs.

Lithium battery technology improvement direction

| Technology Direction | Improvement Effect | Maturity | Degree of Resolution for Core Shortcomings | Application Prospects |

|---|---|---|---|---|

| Silicon-Carbon Anode Technology | 20-30% Increase in Energy Density | Early Stage of Commercialization | Alleviates Range Anxiety | High-End Electric Vehicles, Drones |

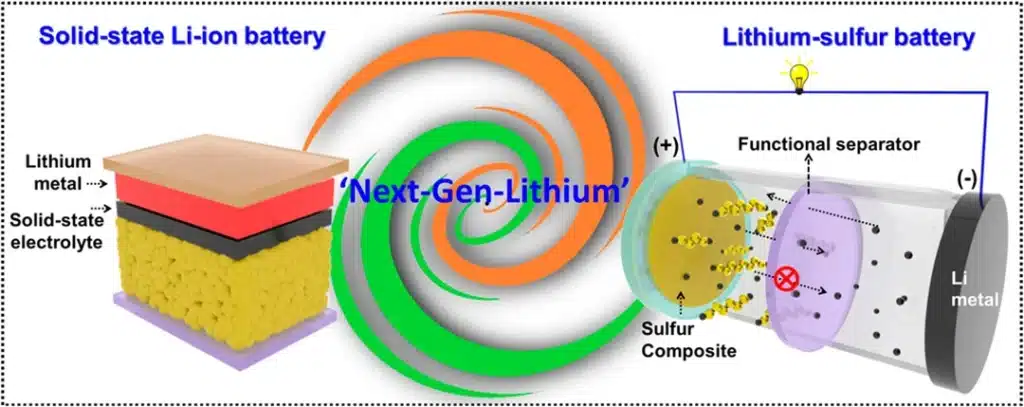

| Solid-State Electrolyte | Significantly Improved Safety | Laboratory Stage | Resolves Safety Hazards | Potentially Commercialized by 2027 |

| New Battery Management System | 15-25% Extension of Service Life | Commercially Available | Alleviates Lifespan Issues | Applicable to the Entire Industry |

| New Cathode Materials | 80% Reduction in Cobalt Usage | Mass Production Stage | Reduces Costs | Large-Scale Energy Storage, Electric Vehicles |

| Self-Healing Electrode Technology | 30-50% Extension of Cycle Life | Research & Development Stage | Resolves Lifespan Issues | Potentially Commercialized within Five Years |

Development of alternative energy storage technologies

- Sodium-ion batteries: 30-40% cheaper than lithium-ion batteries, abundant resources, but 20-30% lower energy density, suitable for large-scale energy storage.

- Hydrogen fuel cells: high energy density, fast charging, but insufficient infrastructure, high cost, suitable for long-distance transportation.

- Liquid flow battery: It can achieve 8-10 hours of long-term energy storage and a cycle life of more than 15,000 times, but it is large in size and has low power density.

- Compressed air/pumped hydro: Suitable for ultra-large-scale, long-term energy storage, but with strict geographical restrictions.

Lithium battery recycling strategy

Primary applications (high performance requirements): electric vehicles, high-end electronic equipment (3-5 years)

Secondary applications (medium performance): home energy storage, backup power (follow-up 5-7 years)

Level 3 applications (low performance requirements): fixed energy storage, low-power equipment (extended for another 3-5 years)

Material recycling: Extract rare metals such as lithium, cobalt, and nickel to achieve a circular economy

Through automated production and material optimization, our lithium battery factory has reduced the battery production defect rate to below 0.5%, while increasing the cycle life by 40%, successfully solving some life and cost issues and providing more reliable products to global customers.

The latest lithium battery technology development and trends in 2025

The lithium battery field has witnessed important breakthroughs in 2025, especially in terms of safety, life and cost. These advances mainly come from innovations in materials science, intelligent battery management and large-scale manufacturing. China, as the world’s largest lithium battery producer, is leading this technological change. You can visit our various lithium-ion battery products.

The global lithium battery market is expected to reach $135 billion in 2025, with an annual growth rate of 18-20%. The market share of lithium iron phosphate batteries (LFP) continues to rise, and is expected to account for 40-45% of the global lithium battery market. Especially in the fields of large-scale energy storage and commercial vehicles, the disadvantages of lithium iron phosphate batteries are being gradually overcome by new technologies, and their safety and cost advantages are becoming more and more obvious.

Latest progress overview

- Semi-solid-state battery technology breakthrough: Semi-solid-state batteries will enter the commercialization stage in 2025, with energy density increased by 25% and safety risks greatly reduced.

- Lithium battery recycling technology is mature: recycling efficiency has been increased to more than 85%, significantly reducing dependence on raw materials, and it is expected to reduce lithium battery production costs by 15% by 2026.

- AI battery management system popularization: using machine learning to optimize charging and discharging strategies, extending battery life by 20-30%, especially in the field of electric vehicles.

- Commercialization of low-cobalt/cobalt-free battery technology: Reduce dependence on rare metals, reduce costs by 15-25%, while reducing supply chain risks and environmental impact.

- Modular design and intelligent diagnosis: facilitate maintenance and cell replacement, extend the service life of the entire battery system and reduce the overall cost of ownership.

Chinese lithium battery manufacturers are leading the cost reduction trend through large-scale production and technological innovation. Data shows that the production cost of lithium batteries in large Chinese factories has been reduced by 35-40% compared with 2020. At the same time, in terms of life and safety issues, the standard version of lithium batteries in 2025 has achieved a cycle life of 5,000-8,000 times, which is significantly higher than the level a few years ago.

Conclusion

Although lithium-ion batteries have disadvantages such as safety risks, life limitations and high costs, these problems can be effectively alleviated through the right selection and management strategies. The key is to choose the right battery type and configuration based on your specific application needs, while adopting scientific usage and maintenance methods.

When choosing a lithium battery solution, safety requirements, service life expectations, and budget constraints should be considered comprehensively. For applications where safety is critical, lithium iron phosphate batteries may be a better choice; for scenarios that require high energy density, a new generation of ternary lithium batteries can be selected; and for cost-sensitive large-scale projects, a cascade utilization strategy can be considered.

Hongyitai has been focusing on lithium-ion battery production for more than 10 years, helping customers in 100 countries and regions around the world to customize lithium-ion battery solutions. As China’s leading lithium battery factory, we provide a complete product line from battery cells to systems, and our professional team can provide customized solutions based on your specific needs.

FAQs

Under normal use conditions, the probability of modern lithium batteries exploding is extremely low (less than 0.001%). Most safety accidents are caused by the use of inferior products, physical damage or extreme use environments. If you choose products produced by regular manufacturers and follow the instructions for use, the safety risk can be reduced to a very low level.

Yes, lithium iron phosphate battery (LFP) is safer and has better thermal stability than lithium cobalt oxide (LCO). The disadvantages of lithium iron phosphate battery mainly include lower energy density (25-30% lower than ordinary lithium battery), poor low temperature performance and heavier weight. It is suitable for application scenarios with high safety requirements and low energy density requirements.

Modern electric vehicle batteries typically last 8-12 years or 150,000-300,000 km, depending on battery type and usage habits. Disadvantages of lithium ion battery in electric vehicles include high replacement costs, currently replacing a complete battery pack costs 60,000-120,000 RMB, but this cost is decreasing with technological development and improved recycling systems.