Forklift Batteries

Forklift batteries are the core component of electric forklifts, providing them with power. There are three main types of forklift batteries: Flooded Lead-Acid, AGM Battery, and Lithium-Ion Battery. With the increasing demand for high energy efficiency and long lifespan, Lithium Iron Phosphate (LiFePO4) batteries are gradually becoming mainstream.

We primarily produce 3 types of batteries: 24-volt forklift battery, 36-volt forklift battery, and 48-volt forklift battery. As a forklift battery manufacturer in China, we can also help customers customize forklift batteries with other voltages.

Longer lifespan

Lifepo4 battery lifespan is 4 times than lead acid.

More powerful

Support fast charging and flat discharge curve.

No maintenance

No need to add water to forklift battery.

Environment friendly

Lithium-ion batteries have no emissions.

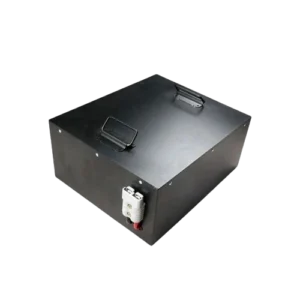

forklift battery product

Below are 3 models of Lithium Iron Phosphate (LiFePO4) forklift batteries. They have a cycle life of over 6000 cycles, and the overall charge-discharge curve is very stable, ensuring high efficiency for forklifts.

We can also produce small 12V forklift batteries, with a lifespan of 8-10 years.

- Lithium Battery for Forklift

24 volt forklift battery

Nominal voltage: 24V

Nominal capacity: 100Ah

Rated energy: 2400Wh

Max Continue Current: 100A

Weight: 12Kg

Size: 328*172*215mm

Temperature: -20~60℃

36 volt forklift battery

Nominal voltage: 36V

Nominal capacity: 200Ah

Rated energy: 7200Wh

Max Continue Current: 100A

Weight: 38Kg

Size: 328*172*215mm

Temperature: -20~60℃

48 volt forklift battery

Nominal voltage: 48V

Nominal capacity: 200Ah

Rated energy: 9600Wh

Max Continue Current: 100A

Weight: 52Kg

Size: 328*172*215mm

Temperature: -20~60℃

How to select your right forklift battery charger

Forklift chargers need to ensure safety and reliability while increasing charging speed. Below are three common types of chargers.

Standard Charger: Typically charges at a 0.2C rate, taking 5-6 hours to fully charge. This type of charger is beneficial for battery health and extends battery life.

Fast Charger: Usually charges at a 0.5C rate or higher, taking only 1 hour to fully charge. It is suitable for situations where forklifts are used frequently.

Charging Station: Generally takes 1 hour to fully charge and can support simultaneous charging for multiple forklifts. It is ideal for large work platforms.

Factors to Consider When Choosing a Forklift Battery Charger:

- Determine the type of forklift battery you have and how long you want it to take to fully charge.

- If the forklift is not used for a long time, try to maintain the battery at 50% charge.

Advantages and Disadvantages of Forklift Batteries

Regardless of the type of forklift battery, consider your budget, usage frequency, cycle life, and charging convenience. Strive to maximize forklift operating efficiency and reduce operating costs.

Regardless of the type of forklift battery, consider your budget, usage frequency, cycle life, and charging convenience. Strive to maximize forklift operating efficiency and reduce operating costs.

| Battery Type | Advantages | Disadvantages |

|---|---|---|

| Flooded Lead-acid | Low cost, mature battery technology, and low operational investment. | Requires regular maintenance and water refilling; charging time is 6-8 hours, and the lifespan is relatively short. |

| LiFePO4 Battery | Supports fast charging, fully charges in 1 hour. Over 6000 cycles, 8-10 years lifespan. | High initial investment, but it’s a one-time cost. |

| AGM Battery | Low maintenance requirement, no need for water refilling. | Higher cost compared to traditional lead-acid batteries. Performance gradually decreases with more charging cycles. |

What you should know forklift battery connector

Forklift battery connectors are crucial interfaces between the electric forklift battery and the charger or vehicle’s electrical system, ensuring smooth current transmission. There are two main types of connectors: flat connectors and European DIN connectors.

The first type uses flat wiping technology and connects by rotating 180 degrees. A common brand is Anderson.

The second type involves pin and socket connections, resulting in male and female connectors.

FAQs for electric forklift batteries

Forklift batteries should be charged when the power drops to 20% to 30%. Many modern electric vehicles have a 20% power retention feature.

Avoid deep discharge: When the battery level drops below 20%, it may affect the battery cycle life and reduce its performance.

Extend battery life: Our lithium batteries have a cycle life of over 6000 cycles. Charge and discharge them shallowly whenever possible.

Optimize charging efficiency: Charging when the battery level drops to 20% to 30% ensures that each charge is fully utilized.

Avoid overcharging: Overcharging can cause the battery to overheat and may lead to safety issues. Choose chargers with an automatic shut-off feature.

In summary, following these charging recommendations can maximize the lifespan of forklift batteries and ensure their efficient and safe operation.

The lifespan of forklift batteries primarily depends on the battery type, usage frequency, maintenance, and working environment. Here is the expected lifespan of different types of forklift batteries:

Lead-Acid Batteries

- Charging Cycles: Typically 1,000 to 1,500 cycles.

- Lifespan: Usually around 5 years.

Lithium-Ion Batteries

- Charging Cycles: Typically 5,000 to 6,000 cycles.

- Lifespan: Usually around 8-10 years. Even in multi-shift operations, lithium-ion batteries are a great long-term choice due to their fast charging and charging station advantages.

Factors Affecting Battery Lifespan

- Usage Frequency: Frequent charge and discharge cycles will shorten battery lifespan.

- Maintenance: Lead-acid batteries require regular maintenance, such as water refilling, cleaning, and equalizing charges. Lithium-ion batteries do not require this.

- Working Environment: Extreme temperatures (too high or too low) can negatively impact battery performance.

Lead-acid batteries use sulfuric acid as the electrolyte, with a typical concentration of about 37% by weight. Based on the total weight of the battery, the sulfuric acid content can be estimated.

For an electric forklift battery weighing 2,000 pounds, the calculation is: 2000 lbs × 0.2 = 400 lbs of sulfuric acid.