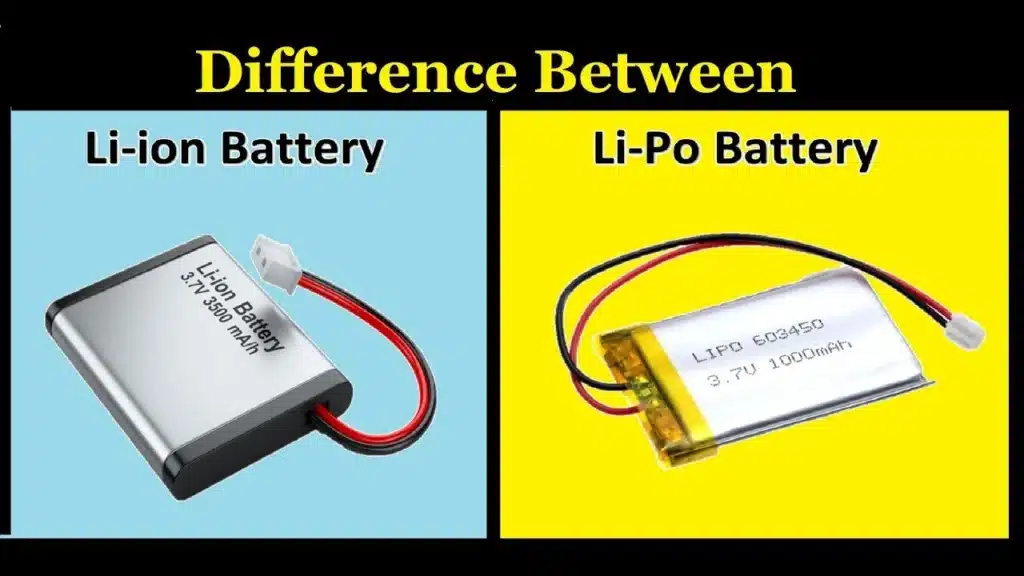

You may have heard of lithium polymer batteries and lithium ion batteries, but you may be confused about what the difference is between the two? Which one is better? This article explores the difference between the two in depth, so that you can clearly distinguish between the two batteries.

Table of Contents

ToggleWhat is lithium-ion battery

Lithium-ion battery does not just refer to a specific type of battery, it is actually a very broad technology category. It includes a variety of different chemical systems, such as lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate, NMC/NCA batteries. Each system has its own unique performance characteristics. Lithium-ion batteries often exist in two physical forms: cylindrical and directional.

What is lithium polymer battery

LiPo battery is a type of lithium-ion battery. The conductive medium inside is polymer, not liquid. Its outer shell is usually aluminum-plastic film, which is soft. The biggest highlight of li-polymer battery is that it has flexible shape and can be made very thin.

Lipo battery VS lithium-ion battery

The following compares the differences between lithium-ion batteries and lithium polymer batteries from 8 different angles.

Electrolytes

Electrolyte is a carrier that carries lithium ions. Traditional lithium-ion batteries use liquid electrolytes, and to prevent leakage, the outer shell must be tightly wrapped with a steel shell. However, the electrolyte of lithium polymer batteries is not pure liquid, but a gel-like jelly, which can effectively free lithium ions and greatly reduce the risk of leakage, so that it can be packaged in a lightweight and flexible aluminum-plastic film soft package (pouch).

Physical form and packaging

Lithium-ion batteries (18650, 21700 and square batteries) are usually encapsulated in a sturdy metal (steel or aluminum) casing or a hard plastic shell because the rigid shell provides the necessary sealing to prevent leakage of the internal liquid electrolyte. The hard shell can also withstand certain internal pressure changes and external physical impacts, which can better protect the battery.

Lithium polymer batteries are packaged in flexible aluminum-plastic composite films, and their most typical feature is their flat, thin appearance. Soft-pack packaging allows batteries to be designed into a variety of non-standard, customized shapes and extremely thin thicknesses to maximize the use of the limited space in the device’s battery compartment. This can also reduce the weight of the battery.

Shape flexibility

Traditional lithium-ion batteries have a relatively fixed shape, with a rigid shell that holds liquid electrolytes and provides structural protection, so their shapes are standardized cylindrical and square.

Lithium polymer batteries are highly shaped and flexible, thanks to their gel and solid electrolytes and flexible soft-pack packaging. LiPo batteries can be as thin as 0.5mm, suitable for smartphones and mobile payment devices, and can even be customized in various irregular shapes (L-shaped, trapezoidal, ring-shaped, etc.) to meet specific size requirements.

Energy density

LiPo is essentially a variant of Li-ion technology, and from the perspective of chemical materials, the theoretical energy density upper limit of the two is similar. However, the volume energy density of LiPo batteries is slightly higher, and the soft package packaging eliminates the volume and wall thickness of the rigid shell.

In terms of weight energy density, there is not much difference between the two, which ultimately depends on the specific chemical material ratio used inside the battery.

Power density

Lipo batteries have the advantage of high rate discharge, and are particularly suitable for aircraft models (RC), drones, competition-level power tools, etc. It can provide very large currents in a short time to drive motors, such as 20C, 30C, 100C rate.

Traditional lithium-ion batteries also have high-power discharge capabilities and are used in power tools, electric vehicles, and electronic cigarette products. Its discharge rate can reach 5C, 10C, or even more than 20C.

Safety

Lithium polymer batteries have a weak ability to resist external physical damage and are prone to leakage and other risks. In the event of overcharge, over discharge, or internal short circuit, the Lipo battery may swell, smoke, or even catch fire, so its safety depends on the PCM.

Traditional lithium-ion batteries can withstand high-intensity external extrusion and impact. If it is short-circuited or extremely abused, it still has the risk of thermal runaway. Therefore, in addition to the inherent safety valve, the intelligent BMS multiple protection of lithium batteries is essential.

Costs

The soft pack battery process involves the lamination, winding and thermal packaging of the electrode sheets. Compared with high-speed winding, it may be more complicated. The core process of lithium-ion batteries is high-speed winding, and the technology is very mature.

Standardized cylindrical batteries such as 18650 and 21700 have formed a huge production scale, and the cost per lithium battery has been greatly reduced. However, since the size and shape of LiPo batteries often need to be customized according to specific equipment, their standardization is relatively low.

With the same capacity and similar technology level, traditional cylindrical and square lithium-ion batteries (especially 18650/21700) often have lower manufacturing costs.

Cycle life

The cycle life of lithium-ion batteries is not affected by the casing and mainly depends on the chemical composition and production process.

LiPo and traditional lithium-ion batteries can use exactly the same chemistry, so their theoretical cycle life is the same.

Below is a summary of the advantages and disadvantages of the two batteries & a comparison table

| Feature | Traditional Li-ion | Lithium Polymer (LiPo) |

| Electrolyte | Liquid | Solid / Gel Polymer |

| Packaging | Hard Case (Cylindrical / Prismatic) | Pouch Cell (Soft Pouch) |

| Shape Flexibility | Low | High (Thin, custom shapes) |

| Energy Density (Volumetric) | Good | Potentially Slightly Higher (esp. thin formats) |

| Power Density | Medium to High | Can be Very High (specific high-rate types) |

| Safety (Physical) | More Robust (Hard case protection) | More Vulnerable (Pouch easily damaged) |

| Safety (Internal) | Requires BMS, Risk of Thermal Runaway | Requires precise BMS, Higher risk if punctured/overcharged |

| Cost | Generally Lower | Potentially Higher |

| Main Advantages | Mature tech, Cost-effective, Physically robust | Lightweight, Thin, Flexible form factor, High energy density potential |

| Main Disadvantages | Limited shapes, Energy density limitations | Less physical protection, Potential for swelling, Higher cost |

Applications

Traditional lithium-ion batteries have the advantage of large-scale production due to their standardized size. They are commonly used in electric vehicles (such as early and some current Tesla models), power tools (electric drills, electric saws, electric screwdrivers), scooters, high-power flashlights, and energy storage systems (from small household to large grid-level energy storage).

Lithium polymer batteries are commonly used in mobile phones, notebooks, drones, smart watches, TWS headphones, and portable medical devices because of their lightness, thinness, and strong customization capabilities.

Which is better

The choice of battery technology depends largely on the specific application and priorities.

When you are looking for thinness and size flexibility, lithium polymer batteries are your best choice.

When cost and stable supply are the top priorities, 18650 or 21700 batteries are your first choice.

When you pursue extremely high discharge rates, high-performance lithium polymer batteries dominate in the fields of model aircraft, drones, etc. due to their light weight and powerful instantaneous power output.

Here, no one battery is necessarily better than another. You need to look at the core requirements of your product: form factor, weight, energy density, cost, power characteristics, or other factors – and choose the battery technology that best meets these key needs.

Conclusion

Lithium polymer batteries are essentially a special form of lithium-ion batteries. The core differences are mainly reflected in the electrolyte form and the packaging method (soft pack vs. hard shell). This directly leads to different advantages and characteristics in terms of shape flexibility, safety, energy density (especially volume energy density) and cost structure.

There is no absolute better, the key to choose is which battery is more suitable for you. Of course, you are welcome to contact us to get the best lithium battery solution.