Lithium battery balancing is a technology that ensures that each single cell in the battery pack maintains similar power and voltage, which can significantly improve the performance and service life of the battery pack. When the battery voltage difference reaches more than 20mV, balancing is required, especially in the range of 20-50mV, the balancing effect is best. Correct use of balancing technology can effectively extend the range of new energy vehicles and reduce performance losses caused by battery inconsistency.

Last updated: May 2025 | Estimated reading time: 8 minutes

This article will answer your questions:

- Why do lithium-ion batteries need to be balanced? What are the hazards of voltage difference to batteries?

- What are the differences and application scenarios between active and passive balancing technologies?

- How to reduce battery voltage difference and extend battery life in daily use?

- How does the modern BMS system achieve intelligent battery balancing?

- Simple and practical battery maintenance tips to help you improve the performance of new energy vehicles

Table of Contents

ToggleWhat is lithium battery balancing?

Lithium battery balancing is a technology that eliminates or reduces the difference in power between individual cells in a battery pack by monitoring and adjusting the voltage of each cell in the battery pack. This is particularly important for battery packs composed of multiple cells connected in series, such as the power battery system of electric vehicles. Balancing technology can ensure that each battery cell is in the best working condition and prevent some cells from being overcharged or over-discharged.

The main reason why lithium-ion batteries need to be balanced is that there are inevitable manufacturing differences and inconsistent usage of each single cell in the battery pack. During the production process, even batteries from the same batch will have slight differences in parameters such as capacity and internal resistance. As the use time increases, these differences will be magnified, resulting in the “short board effect” in the battery pack, that is, the performance of the entire battery pack is limited by the weakest single cell.

The hazards and impacts of battery imbalance

Unbalanced cells in a battery pack can lead to a series of problems:

| Problem Type | Specific Manifestation | Technical Reason | Practical Impact for You |

|---|---|---|---|

| Range Reduction | Reduced Usable Capacity | Shortest Plank Effect Limits Total Discharge | Decreased driving range per charge |

| Reduced Lifespan | Premature Battery Failure | Overcharge/Discharge of Individual Cells | More frequent battery replacements needed |

| Safety Hazard | Overheating, Bulging Risk | Individual Cells Operating Outside Safe Limits | Increased risk when using the vehicle |

| Reduced Charging Efficiency | Extended Charging Time | Individual Cells Reaching Cut-off Voltage Earlier | Charging takes longer, worsened experience |

How to tell if your battery needs equalization

- Range is significantly reduced: If you find that the vehicle’s range is more than 15% lower than when it was new, there may be a balancing problem.

- Charging time becomes longer: The battery pack charges significantly slower, especially when charging above 80%.

- Uneven battery health: The single cell voltage difference detected by the diagnostic equipment exceeds 20mV.

A Tesla Model 3 owner found that the vehicle’s range dropped from the original 450 kilometers to 380 kilometers. After testing, it was found that the voltage difference in the battery pack reached 60mV. After professional balancing service, the range was restored to more than 430 kilometers.

For more information about the causes of battery capacity decay, please refer to the complete guide to new energy vehicle battery maintenance.

Active balance technology

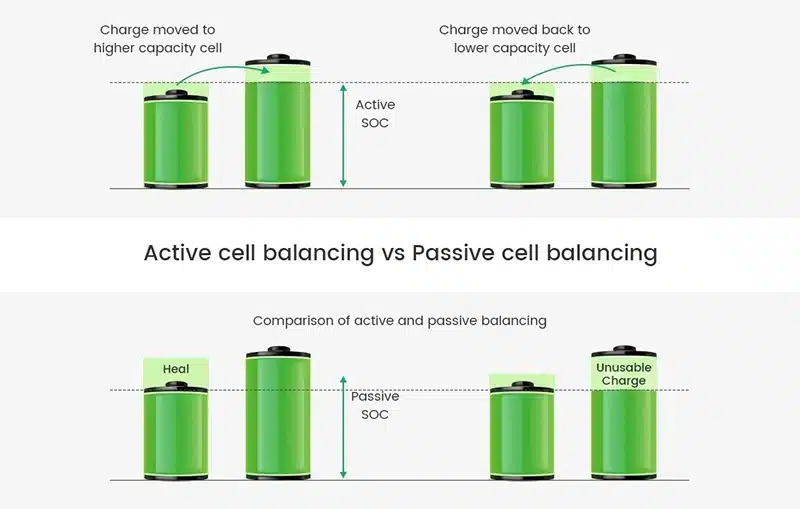

Active balancing is an efficient battery balancing technology that actively transfers energy from high-power batteries to low-power batteries to achieve power balance among cells in the battery pack. Compared with passive balancing, active balancing does not convert excess energy into heat waste, but realizes energy redistribution, so it is more efficient.

Active balancing usually uses DC-DC converters, capacitors or inductors as energy transmission media, and transfers the energy of high-voltage monomers to low-voltage monomers through control circuits. According to conversion efficiency and implementation methods, active balancing can be divided into switched capacitor type, transformer type and bidirectional DC-DC conversion type.

Advantages and limitations of active balancing:

Active balancing technology has the following advantages:

- High energy utilization efficiency: Transfer rather than consume excess energy, energy utilization rate can reach 80-95%.

- Fast balancing speed: The balancing current is usually 1A-10A, suitable for large-capacity battery packs.

- Wide application scenarios: Especially suitable for large-capacity applications such as electric vehicles and large energy storage systems.

- Reduced heat generation: Less heat is generated during the energy transfer process, reducing the difficulty of thermal management.

But active balancing also has some limitations:

- High cost: The circuit structure is complex and the components are expensive.

- Complex control algorithm: Precise control strategy is required to ensure the balancing effect.

- Reliability challenge: Complex systems mean more potential failure points.

Suitable scenarios for using active equalization:

- Battery systems with a large number of series connections: such as electric vehicle power batteries (usually >100 strings).

- High-value battery systems: lithium battery storage systems with large investments.

- Applications with high efficiency requirements: such as applications with strict requirements on energy conversion efficiency.

- Large-capacity battery systems: large battery packs with a capacity of more than 50Ah.

Tesla uses a complex active balancing system in its electric vehicles that can automatically detect and balance 4,416 battery cells during the charging process, keeping the battery pack consistency at an extremely high level, effectively extending battery life and improving energy efficiency.

For more information about electric vehicle BMS system design, please check out the core technology analysis of electric vehicle battery management system.

Passive balance technology

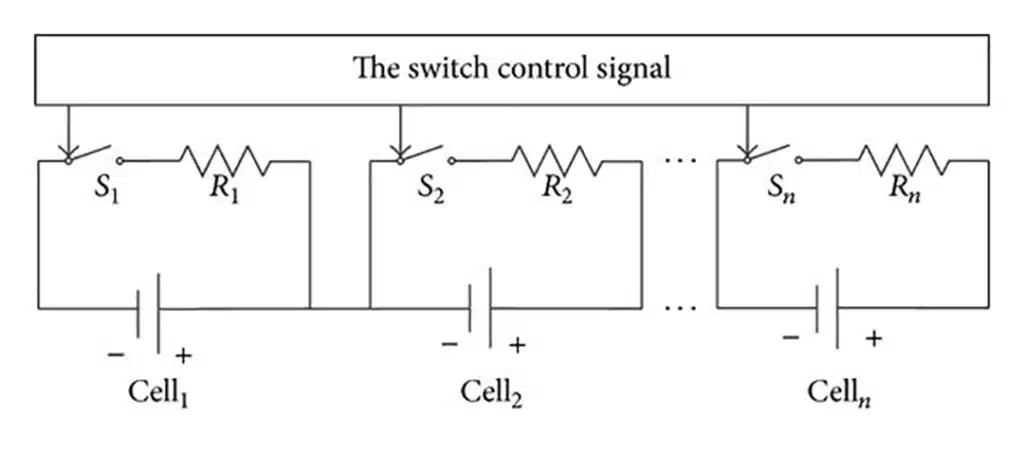

Passive balancing achieves the balance of power in each cell in the battery pack by consuming the excess energy of the high-power battery. It usually uses resistance discharge to convert the excess energy of the high-power battery into heat energy. Although this method is simple and direct, it will cause energy waste and is relatively inefficient.

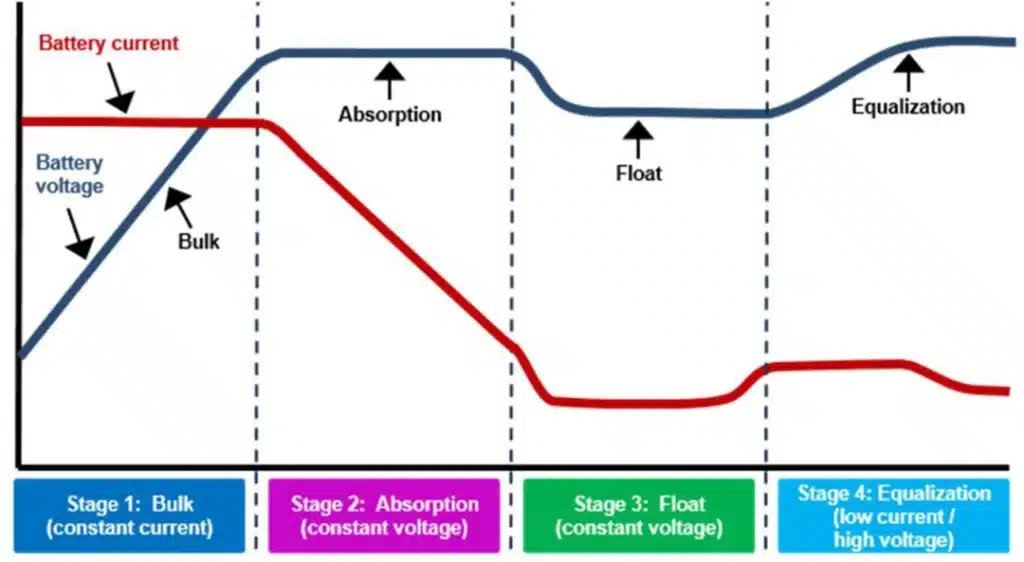

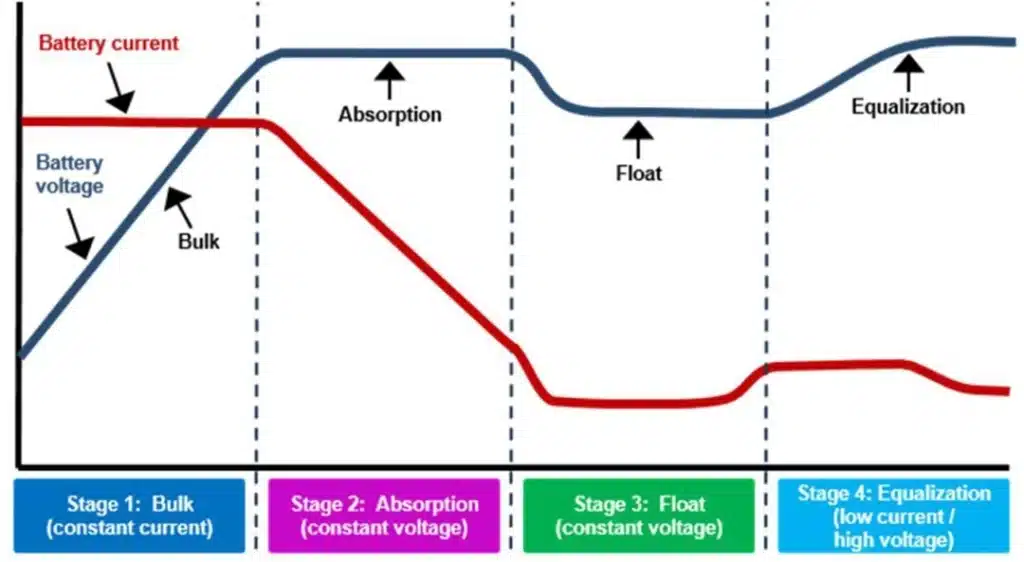

Passive balancing is most commonly used at the end of charging. When the voltage of a single cell reaches the upper limit, the balancing circuit will consume its excess power through the resistor, while allowing other batteries to continue charging until the voltages of all batteries are close to the same. This technology is simple to implement and low in cost, but the balancing speed is slow, usually only tens to hundreds of milliamperes of balancing current.

Applications and advantages of passive balancing:

- Simple circuit: Usually only switches and resistors are needed, and the structure is simple and reliable.

- Low cost: Few components are required, and the cost is only 15-30% of active balancing.

- Simple control logic: Just judge the voltage level to perform corresponding control.

- Suitable for small systems: For small-capacity battery packs, efficiency loss is acceptable.

| Application Scenario | Typical Balancing Current Value | Balancing Time | Cost-Effectiveness |

|---|---|---|---|

| Portable Electronic Devices | 50-100mA | Long (Several Hours) | High (Low Cost) |

| Power Tool Batteries | 100-300mA | Medium (1-3 Hours) | Medium |

| Small Electric Vehicles | 200-500mA | Medium (Several Hours) | Medium |

| Home Energy Storage Systems | 300-800mA | Long (Several Hours) | Medium |

Practical tips and suggestions for users:

- Small capacity application choice: For small device batteries such as laptops and mobile phones, passive balancing is sufficient.

- Cost sensitive projects: If the budget is limited, passive balancing is an affordable choice.

- Simple application scenario: In situations where fast balancing is not required, passive balancing can meet the needs.

An electric bicycle manufacturer uses a passive balancing solution in its products, performing balancing at the end of each charge, effectively controlling the voltage difference of the battery pack cells to within 15mV. The cost is only 1/4 of the active balancing solution, but the battery life is increased by about 30%.

How to reduce pressure difference in daily use

The best way to reduce the voltage difference of lithium batteries is to develop good charging and discharging habits, especially to avoid frequent fast charging and deep discharge. Studies have shown that 80% of battery imbalance problems are directly related to charging habits. By using batteries properly, you can significantly extend battery life and maintain good consistency.

In daily use, you should try to avoid completely discharging the battery or frequently using the fast charge function. The ideal charging and discharging range of lithium batteries is between 20% and 80%, which can reduce the performance differences between battery cells, especially for NMC lithium batteries.

Practical battery maintenance tips:

- Control the charging rate: Try to use standard charging instead of fast charging, especially after the battery exceeds 80%.

- Avoid extreme temperatures: Use and charge within the temperature range of 0-40°C, avoid extreme temperatures.

- Perform a full charge and discharge cycle regularly: Perform a full 0-100% charge and discharge cycle after every 15-20 normal charges and discharges.

How to determine and monitor battery voltage difference

- Use battery monitoring tools: The battery voltage monitor can display the voltage of each cell in real time.

- Pay attention to the charging curve: An abnormally fast or slow voltage rise at the end of charging indicates that there may be a voltage difference.

- Compare discharge performance: Record and compare the changes in discharge time under the same usage conditions.

A BMW i3 owner adhered to standard charging (rarely used fast charging) and regularly performed complete charge and discharge cycles. After 3 years, the battery health remained above 92%. During the same period, the battery health of the same model that frequently used fast charging averaged only about 85%.

Development of balancing technology in BMS systems

The balancing technology of battery management system (BMS) has evolved from simple passive balancing to intelligent adaptive balancing system, combining artificial intelligence and big data analysis to optimize the balancing strategy. Modern BMS not only focuses on voltage balancing, but also considers multi-dimensional coordinated control such as capacity balancing and temperature balancing to maximize the performance of the battery pack.

The latest BMS system in 2025 can predict the performance trend of single cells through machine learning algorithms, and perform preventive equalization in advance, rather than passively responding after the pressure difference forms. This predictive equalization technology can intervene in the early stages of the pressure difference formation, significantly reducing the performance loss caused by the accumulation of pressure difference.

The development of BMS balancing technology has gone through the following stages:

- Basic passive balancing: a simple resistor consumes energy.

- Basic active balancing: capacitors or inductors transfer energy.

- Intelligent passive balancing: dynamically adjust the balancing strategy according to SOC and SOH.

- Adaptive active balancing: comprehensively consider multiple factors such as voltage, capacity, and temperature.

- Predictive intelligent balancing: use AI to predict changes in battery status and balance in advance.

The latest BMS balancing technology trends:

- Wireless balancing technology: Use wireless energy transmission technology to transfer energy between cells.

- Multi-dimensional balancing algorithm: Consider multiple parameters such as voltage, capacity, temperature, internal resistance, etc. at the same time.

- Cloud big data support: Use cloud computing to analyze fleet data to optimize balancing strategies.

- Balance and charging integration: Charging piles and on-board BMS work together to achieve optimal balancing.

A luxury electric vehicle brand’s new model launched in 2025 uses AI predictive balancing technology. By analyzing battery historical data and usage patterns, it performs targeted balancing of cells that are prone to imbalance in advance, so that the battery pack voltage difference is maintained within 10mV all year round, extending the battery life by about 25% compared with traditional balancing technology.

For more detailed information about the intelligent BMS system, please refer to intelligent battery management system technology.

The latest lithium battery balancing technology development and trends in 2025

- High-performance active balancing chip: The balancing current of the new generation balancing chip has reached 15A, and the energy efficiency exceeds 95%.

- Adaptive balancing strategy: Automatically optimize the balancing solution according to the battery pack historical data, usage environment and load characteristics.

- Wireless balancing technology: Using wireless energy transmission technology, energy can be transmitted between cells without physical connection.

- Thermocouple balancing: Combine thermal management and power management to achieve temperature balancing and voltage balancing at the same time.

For ordinary consumers, these technological advances mean faster charging, more stable driving and longer battery life for electric vehicles. Market research shows that the battery system life of electric vehicles using the latest balancing technology is extended by an average of 35%, while improving energy efficiency by 10-15%, which directly translates into longer driving range and lower cost of use.

Conclusion

Lithium battery balancing technology is the key to ensuring battery pack performance and extending service life. Active balancing is efficient but costly through energy transfer and is suitable for large systems; passive balancing is simple and economical through resistor discharge and is suitable for small systems. Correct charging and discharging habits are crucial to reducing voltage differences, especially avoiding frequent fast charging and extreme temperature use.

We, Hongyitai, have been focusing on lithium-ion battery production for more than 10 years and have helped customers in more than 100 countries and regions around the world to customize high-performance lithium battery solutions. Focusing on the continuous innovation of lithium battery technology, our battery balancing technology ensures that the product has a 30% longer service life and more stable performance than the industry standard. If you have any questions, please contact us.

FAQs

Yes, lithium-ion battery packs do need balancing, especially systems consisting of multiple single cells in series. Balancing can prevent overcharging and over-discharging, extend battery life, and improve energy utilization. Tip: Even high-quality batteries will produce inconsistencies over time, and regular balancing is necessary maintenance.

The equalization of lithium batteries in series requires a dedicated equalization circuit or equalizer. For professional users, the equalization function of the BMS system can be used; for DIY enthusiasts, a separate equalizer can be purchased and connected to the battery pack. The equalization process is usually performed at the end of charging to make the voltage of each cell reach a nearly consistent state.

Lithium batteries in parallel will naturally balance because the batteries in parallel share the same voltage. However, please note that if the internal resistance of the parallel batteries is very different, it will lead to uneven current distribution. It is recommended to use batteries with similar internal resistance for parallel connection. If it is a complex combination of multiple series and multiple parallels, each series group still needs to be balanced.

Lithium battery active balancing circuits are usually based on capacitors or transformers for energy transfer. The basic design includes a control unit, a detection unit, an energy transfer unit, and an execution unit. Beginners can start with a ready-made balancing chip such as LTC3300 or BQ76940. The key is to choose the right energy transfer components and control strategy to ensure efficient and stable balancing results.

The frequency of battery balancing depends on the battery type and usage. For ordinary electric vehicle users, professional balancing maintenance is recommended every 6-12 months; for users who frequently use fast charging, it is recommended to perform it every 3-6 months. Modern BMS systems will automatically perform a small amount of balancing during the charging process, but it is still important to perform a full balancing regularly.