Lithium battery efficiency is a key indicator to measure the energy conversion ability of the battery during the charging and discharging process. At present, the charging and discharging efficiency of lithium-ion batteries is between 85% and 95%, among which NMC lithium batteries can reach 99.5% charging efficiency, and Lifiepo4 battery has an efficiency of more than 90% under rate discharge conditions. Understanding these data will help you choose the most suitable battery technology.

Last updated: June 2025 | Estimated reading time: 8 minutes

This article will answer your questions:

- What is lithium battery efficiency – the core difference between coulomb efficiency and charge and discharge efficiency

- Efficiency comparison of different battery types – real performance data of ternary lithium vs lithium iron phosphate

- Analysis of factors affecting efficiency – How temperature and charging rate affect your battery performance

- Practical application optimization strategy – efficiency improvement solutions for electric vehicles and energy storage systems

- Future technology development trends

Table of Contents

ToggleWhat is lithium battery efficiency

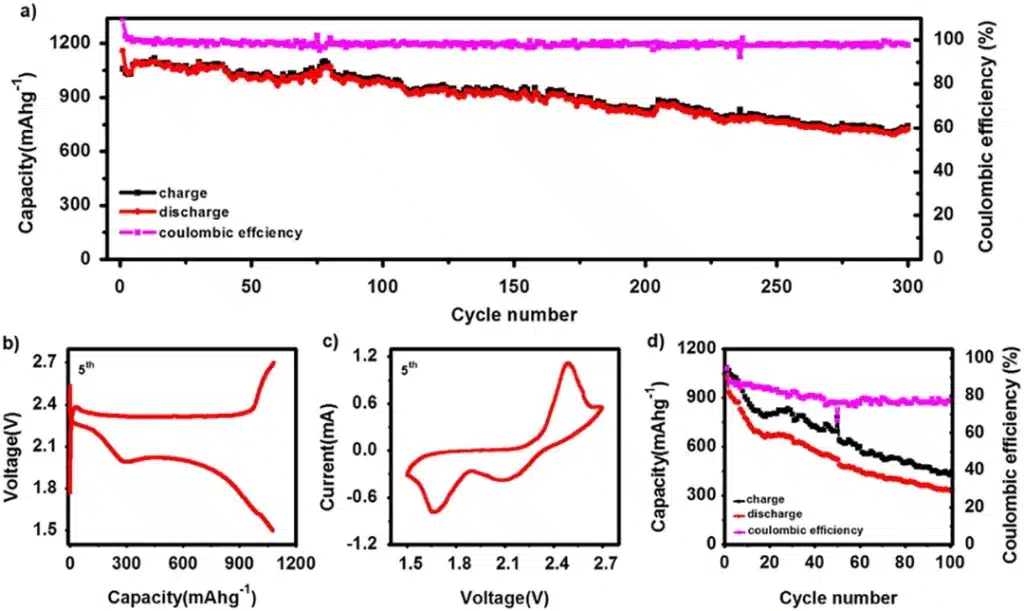

Lithium battery efficiency mainly includes two core concepts: coulomb efficiency and charge and discharge efficiency. Simply put, coulomb efficiency tells you how much power the battery can remember, while charge and discharge efficiency reflects the loss in the energy conversion process.

Coulombic efficiency refers to the ratio of the battery’s discharge capacity to its charge capacity. When you charge a battery 100 degrees, the amount of electricity that can be discharged is a reflection of the coulombic efficiency. The initial coulombic efficiency of current graphite anodes is usually about 90%, which means that during the first charge, about 10% of the lithium ions will remain permanently in the electrode material, forming a protective layer, but will not be able to participate in subsequent cycles.

The charge and discharge efficiency reflects energy loss more directly. This indicator tells you how much of the input electrical energy during charging can actually be stored, and how much can be effectively output during discharge. Currently, the charge and discharge efficiency of mainstream lithium-ion batteries is usually between 80% and 90%.

For your application, these two efficiency indicators focus on different aspects:

- Coulombic efficiency affects battery life and capacity retention, especially in applications with frequent charge and discharge cycles.

- Charging and discharging efficiency directly affects energy costs and system design, and is related to your actual electricity costs.

Actual case: An electric vehicle manufacturer improved the comprehensive charge and discharge efficiency of the power battery pack from 87% to 92% by optimizing the battery management system, directly reducing users’ charging costs by about 6%.

Efficiency comparison of different lithium battery types

NMC lithium batteries perform best in terms of charging efficiency, while LFP batteries have more stable efficiency at high discharge rates. The key to choosing which battery technology to use depends on your specific application needs.

Ternary lithium battery efficiency characteristics

The charging efficiency of ternary lithium batteries can reach 99.5%, which is the highest level among commercial lithium-ion batteries. When using high-quality charging equipment, the charging efficiency is about 95%, and the overall charging and discharging process efficiency is maintained at around 90%.

Advantageous scenarios:

- Applications with high energy density requirements (such as electric vehicles, drones)

- Consumer electronics that require fast charging

- Weight-sensitive portable devices

Lithium iron phosphate battery efficiency characteristics

LiFePo4 batteries can achieve an efficiency of more than 90% under rate discharge conditions, and are particularly stable at high power output. Although the energy density is relatively low, it has obvious advantages in cycle life and safety.

Advantageous scenarios:

- Energy storage system (high cycle life requirements)

- Commercial vehicle power battery

- Base station backup power system (long-term stable operation)

| Battery Type | Charging Efficiency | Discharging Efficiency | Practical Significance for You |

|---|---|---|---|

| Ternary Lithium Battery | 99.5% | 90-95% | Less charging loss, suitable for frequent charging scenarios |

| Lithium Iron Phosphate | 95% | 90%+ | Stable high-rate discharge, suitable for high-power applications |

| Lithium Titanate | 98% | 95% | Strong fast-charging capability, but higher cost |

- Pursuing the highest energy efficiency: Choose ternary lithium batteries, especially suitable for electric vehicles and high-end consumer electronics.

- Focus on long-term stability: Choose lithium iron phosphate, especially suitable for energy storage systems and commercial vehicles.

- Balance performance requirements: Consider the specific working conditions and cost budget.

For more information on battery selection, please refer to our 6 lithium battery types selection guide.

Key factors affecting efficiency

Temperature, charge and discharge rate, battery state and system design will significantly affect the actual efficiency performance of lithium-ion batteries. Understanding the following factors can help you maximize battery performance in practical applications.

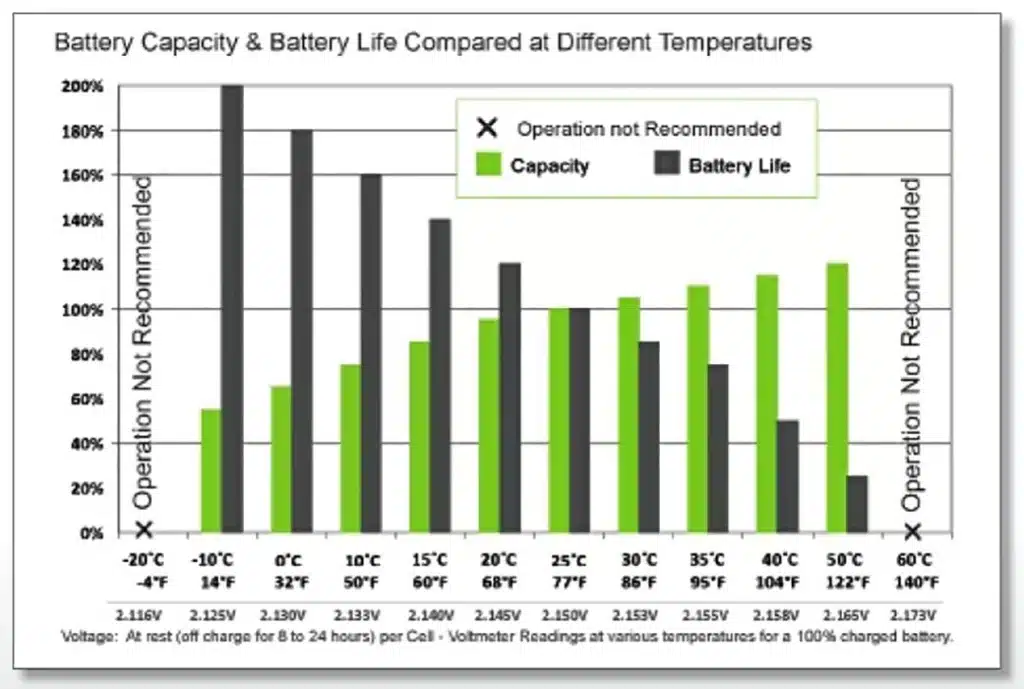

Effect of temperature on efficiency

Temperature is one of the most important factors affecting the efficiency of lithium-ion batteries. The battery’s chemical reaction rates and ion transport capabilities are strongly dependent on operating temperature.

Optimum operating temperature range:

- Ideal temperature: 20-25°C for best efficiency

- Acceptable range: efficiency drop of no more than 5% at 10-40°C

- Extreme conditions: Efficiency drops sharply below 0°C or above 60°C

Effect of charge and discharge rate

The charge and discharge rate (C rate) directly determines the current density and heat of the battery. Although high-rate charge and discharge can provide greater power, it will reduce the overall efficiency.

Practical magnification suggestions:

- Below 1C: Best efficiency, suitable for daily charging.

- 1-3C: Slightly reduced efficiency, suitable for fast charging applications.

- Over 5C: Efficiency drops significantly, only suitable for emergency scenarios.

Effect of battery aging on efficiency

As the number of charge and discharge cycles increases, the internal impedance of the battery increases and the efficiency gradually decreases. Generally speaking:

- After 500 cycles: Efficiency drops by 2-3%

- After 1000 cycles: Efficiency drops by 5-8%

- After 2000 cycles: Efficiency drops by 10-15%

System influencing factors

In addition to the battery itself, the auxiliary losses of the entire system also affect the overall efficiency:

- Power management system: about 2-5% efficiency loss

- Thermal management system: about 1-3% efficiency loss

- Cables and connectors: about 1-2% efficiency loss

Actual case: A storage project in Xinjiang, my country, increased the overall system efficiency from 82% to 88% by optimizing the thermal management system and upgrading the power management chip, saving about 120,000 yuan in electricity bills each year.

Practical application of industry efficiency optimization

Different industries have different requirements for lithium-ion battery efficiency, and targeted optimization strategies can significantly improve the actual application effect. The following are specific optimization solutions for three major application areas.

Electric vehicle battery optimization

Electric vehicles have the most stringent requirements on battery efficiency as this directly affects driving range and charging costs.

Core optimization strategy:

- Thermal management optimization: A liquid cooling system is used to maintain the optimal operating temperature, improving efficiency by 3-5%.

- Intelligent BMS: Dynamically adjust charging and discharging strategies to avoid high-rate losses.

- Energy recovery: Braking energy recovery system improves overall efficiency by 10-15%.

Practical advice:

- Charging habits: Avoid charging in extreme temperatures and choose a charging range of 20%-80%.

- Driving style: Smooth acceleration and rational use of air conditioning, which can improve overall efficiency by 5-10%.

- Maintenance: Regularly check the temperature uniformity of the battery pack and handle abnormal cells in a timely manner.

Maximizing energy storage system efficiency

Energy storage systems usually need to operate stably for a long time, and have higher requirements for cycle efficiency and life.

- Power device selection: Using SiC power devices can improve the inverter efficiency by 2-3%.

- Cooling Design: Optimizes ventilation and heat dissipation paths to reduce operating temperatures.

- Load matching: Adjust the charge and discharge curve according to the actual load characteristics.

Operation and maintenance optimization:

- Balance management: Perform battery balance regularly to maintain the consistency of each cell.

- Preventive maintenance: Monitor the trend of internal resistance changes and identify the risk of efficiency decline in advance.

- Intelligent scheduling: Optimize charging and discharging timing based on electricity prices and load forecasts.

Consumer electronics fast charging technology

Consumer electronics products need to charge quickly while maintaining high efficiency to control heat and extend life.

- Multi-stage charging: A staged charging strategy with high current in the early stage and low current in the later stage.

- Temperature feedback: Monitor temperature in real time and adjust charging power dynamically.

- Material innovation: Use new materials such as silicon nanowire negative electrodes to improve efficiency.

Actual case: By adopting GaN chargers and optimizing battery management algorithms, the mobile phone can increase the 30-minute fast charging efficiency from 78% to 85%, while reducing charging heat by 20%.

Next-generation battery technology efficiency breakthrough

Solid-state batteries, silicon-based anodes, and new electrolyte technologies are driving lithium-ion battery efficiency toward the goal of 95%+. These technological breakthroughs will be gradually commercialized in the next 3-5 years.

Solid-state batteries fundamentally reduce internal impedance and side reactions by eliminating liquid electrolytes, and their theoretical efficiency can reach over 98%.

- Lower internal resistance: Solid electrolytes have higher ion conduction efficiency

- Reduced side reactions: Avoiding the continuous growth and repair of SEI film

- Temperature adaptability: Maintain high efficiency over a wider temperature range

Commercialization progress:

- 2025: Small bulk is used in high-end electronic products

- 2027: Start of trials in electric vehicles

- 2030: Large-scale commercialization is expected

The theoretical capacity of silicon-based negative electrode is 10 times that of graphite, which can significantly improve the energy density and efficiency of the battery.

- Higher capacity: Reduce the proportion of inactive materials and improve overall efficiency.

- Better kinetics: Optimized nanostructures improve ion transport.

- Cycling stability: New binder technology solves volume expansion problem.

New technologies including solid electrolytes, gel electrolytes and highly concentrated electrolytes are improving the internal transport efficiency of batteries.

- Ionic liquid electrolytes: wider electrochemical window and higher ionic conductivity.

- Polymer electrolytes: better interfacial stability and safety.

- Hybrid electrolytes: combining the advantages of liquid and solid.

The latest lithium battery efficiency development and trends in 2025

In 2025, the lithium battery industry has made significant progress in improving efficiency, mainly in the three dimensions of material innovation, system integration and intelligent management. Major manufacturers at home and abroad are increasing their R&D investment to push efficiency indicators towards the goal of 95%+.

- Material breakthrough: Silicon-based anode technology has been industrialized, and the coulombic efficiency has been increased to more than 95% for the first time.

- System optimization: The new generation of BMS chips integrates AI algorithms to optimize charging and discharging strategies in real time.

- Manufacturing process: Dry electrode technology is applied in batches to reduce energy loss in the manufacturing process.

Market data shows that in 2025, the market share of high-efficiency lithium batteries (efficiency>90%) will reach 65%, an increase of 15 percentage points from 2024. Consumers’ awareness of battery efficiency is also increasing, and efficiency indicators have become one of the important factors in product selection.

Conclusion

Lithium battery efficiency involves two core indicators: coulomb efficiency and charge and discharge efficiency. The efficiency of current mainstream products is between 85% and 95%. NMC lithium batteries perform best in terms of charging efficiency, while lithium iron phosphate is more stable at high rate discharge. Temperature, charge and discharge rate, and system design are key factors affecting efficiency.

When choosing a battery, you need to balance efficiency, cost and other performance indicators according to the specific application scenario. Electric vehicles prefer ternary lithium, energy storage systems consider lithium iron phosphate, and consumer electronics products focus on fast charging efficiency. By optimizing usage conditions and adopting advanced management systems, actual application efficiency can be further improved based on existing technologies.

We at Hongyitai have been focusing on lithium-ion battery production for more than 10 years, serving customers in 100 countries and regions around the world, providing customized high-efficiency lithium-ion battery solutions. Our products have rich experience in efficiency optimization and can provide the most suitable battery technology according to different application requirements. Visit our official website for more information.

FAQs

The charging and discharging efficiency of mainstream lithium-ion batteries is between 85% and 95%, among which ternary lithium batteries can reach 99.5% charging efficiency, and lithium iron phosphate batteries have an efficiency of more than 90% at multiple discharge rates. The specific efficiency depends on the battery type, working conditions and usage.

Coulombic efficiency is the ratio of discharge capacity to charge capacity, reflecting the battery's ability to remember charge. High coulombic efficiency means less capacity loss and longer service life, which is especially important for electric vehicles and energy storage systems.

Maintaining a suitable operating temperature, avoiding extreme charge and discharge rates, regularly performing battery balancing, choosing appropriate charging equipment, and adopting an intelligent battery management system can effectively improve usage efficiency.