The role of electrolyte in lithium batteries is self-evident. Without it, lithium ions cannot flow between the positive and negative electrodes, and the battery cannot work. This article comprehensively analyzes the basic principles, key components, main types, and impact mechanisms of electrolytes on battery performance and safety, as well as current challenges and future development trends. This will help you form a systematic, multi-dimensional, and in-depth professional understanding of lithium battery electrolytes.

Table of Contents

ToggleBasic principles of lithium battery electrolyte

The electrolyte in our commonly used batteries is a liquid. Its core function is to act as a channel for lithium ions to shuttle back and forth between the positive and negative electrodes of the battery. Without this channel, the battery cannot be charged and discharged. A good electrolyte should have the following characteristics.

High ionic conductivity: directly affects the charging and discharging speed and power of the battery.

Wide electrochemical stability window: This determines at what voltage the electrolyte can operate stably without decomposing.

Good thermal stability: The electrolyte is not easy to decompose or have problems at high temperatures, which is directly related to the safety of the battery.

Chemical compatibility with electrode materials: No unnecessary chemical reactions should occur with positive and negative electrode materials.

High safety: non-flammable, low toxicity.

Low cost: This is very important for mass production and market application.

Liquid electrolyte composition

Liquid electrolyte mainly consists of the following 3 core parts.

Solvents

Solvents are like the liquid base or carrier environment of the electrolyte. Their main function is to release lithium ions and help them flow smoothly inside the battery. The most common types of solvents are carbonates, esters, and ethers. They also need to have these characteristics: dielectric constant (affecting solubility), viscosity (affecting ion flow rate), melting point/boiling point (affecting the operating temperature range) and stability.

Lithium Salts

Solvents are key substances for lithium ions. Without lithium salts, solvents alone cannot transfer charges. Its core function is to provide lithium ion carriers. For example, the most commonly used LiPF6 (lithium hexafluorophosphate), and others like LiBF4, LiTFSI, LiFSI, etc. The key characteristics of judging the quality of lithium salts include solubility in solvents, the degree of effective ion dissociation it can provide after dissolution, and its thermal stability and electrochemical stability.

Additive

Additives are like functional enhancers added to electrolytes. They are mainly used to fine-tune certain properties of electrolytes, such as improving battery safety and extending battery life.

Key properties and technologies

You can look up specific electrolyte properties, but we’ll cover five key characteristics:

- Ionic conductivity. Factors that affect lithium ion conductivity include viscosity and temperature, and common techniques for measuring it include electrochemical impedance spectroscopy (EIS). Generally, higher conductivity means that the battery may have better power output and faster charging potential.

- Safe operating voltage range. The normal voltage range refers to the high voltage of the positive electrode and the low voltage of the negative electrode. If the range is exceeded, the electrolyte will begin to decompose. Linear sweep voltammetry (LSV) is a typical measurement method.

- Thermal stability. This is directly related to battery safety, and the electrolyte must be able to withstand a certain temperature without easily decomposing, which could lead to dangerous conditions like thermal runaway. DSC (Differential Scanning Calorimetry) or ARC (Accelerating Rate Calorimeter) are commonly used methods to evaluate the stability of electrolytes at different temperatures.

- Viscosity and wettability directly affect the ease with which ions can move. Good wetting is essential to ensure that the entire electrode area works effectively and that ions can reach their destination smoothly.

- Interfacial stability and the solid electrolyte interface (SEI). This is about what happens at the interface where the electrolyte meets the electrode material, especially at the surface of the negative electrode. A thin protective film is formed here, called the SEI film. This film is important: it needs to prevent further side reactions (playing the role of passivating the electrode), but at the same time allow lithium ions to pass smoothly.

Electrolyte Type

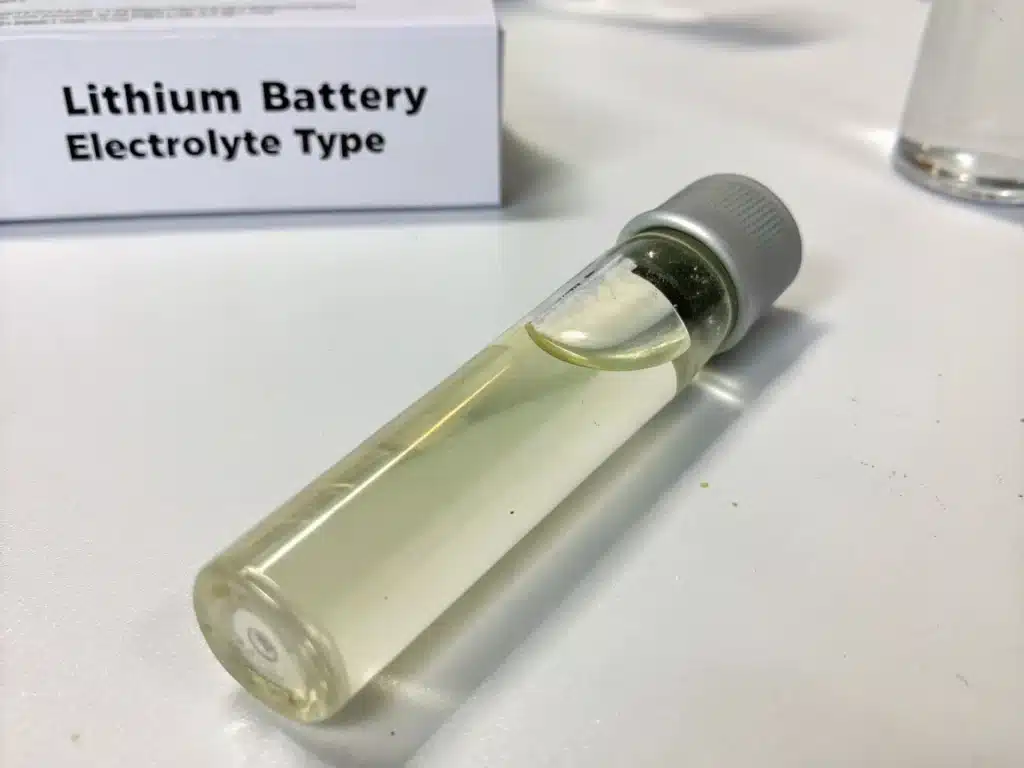

Liquid electrolyte is the most traditional type, and its advantages include high ionic conductivity and good wettability to electrode materials. However, its disadvantages are also obvious. For example, it is flammable, has a risk of leakage, and limits the application of high-voltage batteries.

The second is a gel polymer electrolyte, a state between liquid and solid. Its main advantage is that the risk of leakage is greatly reduced and it can be made flexible, but its ionic conductivity may be lower than that of pure liquid.

The third is solid electrolyte. This is a very popular direction in the current battery research field and is regarded by many as a type of battery that is safe and has high energy density. It has an inherent safety advantage and is considered to be better compatible with lithium metal negative electrodes with extremely high energy density.

The influence of electrolyte on battery performance indicators

We will explain the impact on lithium battery performance from the following five key performance dimensions.

The relationship between energy density and voltage window. The energy density of a battery is approximately equal to the voltage multiplied by the capacity, so an electrolyte with a wider voltage window is crucial for developing batteries with higher energy density.

Power density. This is related to how quickly the battery can release or absorb energy, that is, the ability to quickly charge and output large currents instantly. The ionic conductivity and viscosity mentioned above are key electrolyte factors that determine battery power performance.

Impact on cycle life. The slow decomposition of the electrolyte itself, the stability of the key SEI film, and the effects of various additives in long-term cycles directly affect the cycle life and capacity retention of the battery.

Temperature performance. Electrolyte viscosity and lithium ion conductivity directly affect the power output and charging capacity of the battery in extreme environments.

Safety. We will see that the selection of electrolyte is one of the core links in battery safety design.

Understanding these direct cause-and-effect relationships is absolutely important for selecting the right electrolyte for a specific application and for developing new batteries with improved performance, safety and longevity.

Safety considerations related to electrolytes

The type of electrolyte directly affects battery safety, and its safety analysis is crucial for battery design, application and risk assessment.

Flammability and thermal runaway are the most well-known safety hazards of traditional organic liquid electrolytes.

Electrolyte decomposition pathway: Under certain abuse conditions, the battery will undergo chemical decomposition. Gases can cause the battery to swell or even rupture, generate flammable gases, increase temperature rise, and damage the SEI film.

Electrolyte leakage not only corrodes the electronic components inside the equipment, but also affects the environment.

Current challenges and limitations

In the field of electrolytes, we are now facing the following technical bottlenecks and practical difficulties.

Performance trade-off between ESW and conductivity: A wide electrochemical stability window (ESW) is beneficial to improving energy density, while high ionic conductivity is crucial to improving power performance. But the reality is that it is often difficult to have both. Many times, optimizing one performance indicator may sacrifice another.

The problem of interface instability is that when the electrolyte contacts the high-energy electrode material and the lithium metal negative electrode, a continuous and uncontrolled side reaction will occur at the interface. This will consume the electrolyte, destroy the electrode structure, form an unstable SEI/CEI film, and seriously affect the cycle life and safety of the battery.

Low-temperature performance bottleneck: At low temperatures, the viscosity of the electrolyte increases sharply and the ionic conductivity drops significantly, resulting in serious attenuation of the battery capacity and inability to charge and discharge quickly.

Cost and mass production issues: No matter how good the technology is, it will be difficult to be widely used if it is too expensive or cannot be mass-produced.

Recycling issues. Whether the electrolyte contains toxic substances, as well as the energy consumption and emissions of the production process. And the technical and economic difficulties faced in the recycling and treatment of electrolytes in waste batteries.

Future trends and research directions

We are all actively working to overcome the above challenges and we will develop around the following key paths.

Focus on the development of high-voltage electrolytes. In order to further improve the energy density of batteries, an important way is to use cathode materials with higher working voltages. Therefore, electrolytes that can stably match these new cathode materials are needed.

Electrolytes adapted to lithium metal anodes. Lithium metal anodes are an important direction for achieving a leapfrog increase in battery energy density, but they face serious problems of dendrite growth and low coulombic efficiency, which are mainly related to the interaction of electrolytes. Therefore, we are actively developing and designing new electrolytes to inhibit lithium dendrite growth and stabilize the lithium metal interface.

Non-flammable, safer electrolyte system. Safety is always the lifeline of battery technology. Looking forward to the future, we can fundamentally improve the safety of electrolytes, such as developing completely non-flammable electrolyte chemical systems.

Development and optimization of solid electrolytes. Solid-state batteries are considered to be a strong contender for the next generation of battery technology, and the core lies in solid electrolytes. The research and development of different types of solid electrolytes (polymers, oxides, sulfides, etc.) is an important direction in achieving high-safety, high-energy-density batteries.

Advanced additives and functional electrolytes. For example, designing smart, more specific additives to precisely control electrolyte performance.

Sustainable electrolyte design and recycling. In the future, battery technology must not only have superior performance but also be environmentally friendly. Therefore, it is necessary to develop efficient and economical electrolyte recycling and reuse technology.

Summarize

This article discusses the composition, properties, effects, current challenges and future research directions of electrolytes, so that you can have a more comprehensive understanding of electrolytes. We, Hongyitai, are a leading lithium battery factory in China. If you have any questions, please contact us.

FAQs

Liquid electrolyte: usually composed of organic solvents and lithium salts, has high conductivity and can effectively support the battery's charge and discharge process. Its main disadvantage is that it is volatile and flammable, which poses safety issues.

Solid electrolyte: Made of solid materials (such as ceramics or polymers), it has higher stability and safety. It is safer, it will not leak or burn, but it has poor conductivity and is more expensive to manufacture.

The electrolyte is crucial to the temperature stability of lithium batteries. Liquid electrolytes may decompose or volatilize under high temperature conditions, affecting the stability and safety of the battery. Solid electrolytes have higher chemical stability and can maintain better performance over a wider temperature range, so they are more suitable for use in extreme temperature environments.

By choosing the right electrolyte, the battery can provide better performance and longer life in hot or cold conditions.

The quality of the electrolyte directly affects the cycle life of lithium batteries. High-quality electrolytes have good conductivity and chemical stability, and can effectively reduce the decomposition reaction inside the battery, thereby extending the cycle life of the battery. Poor-quality electrolytes may accelerate capacity decay and even cause battery failure.