Have you ever wondered how safe and reliable your lithium batteries really are? Whether you’re using them in a smartphone, electric vehicle, or energy storage system, the performance of these batteries is crucial. That’s where lithium battery testing comes in.

Testing lithium batteries is essential to ensure they are safe, efficient, and long-lasting. Without proper testing, there’s a risk of failure, safety hazards, and poor performance. For example, a battery that’s improperly tested could overheat, catch fire, or lose its charge too quickly. That’s why manufacturers and regulators use a set of rigorous standards to test batteries before they reach consumers.

Some of the key standards for lithium battery testing include IEC 62133, UL 2054, and UN38.3. These guidelines are designed to assess everything from safety features to performance under different conditions. For instance, testing ensures batteries can handle extreme temperatures, avoid overcharging, and resist short-circuits. These procedures help make sure your battery works when you need it and doesn’t put you at risk.

In this article, we’ll break down the essential testing standards and procedures for lithium batteries. You’ll learn about the different types of tests batteries undergo, from safety tests to performance evaluations. We’ll also cover why these tests matter to you, whether you’re an engineer, buyer, or someone simply concerned about battery safety.

At Hongyitai, we’ve been manufacturing lithium-ion batteries for over 10 years, so we know exactly how important reliable testing is. We’ve tested thousands of batteries to meet industry standards and ensure the highest quality. By reading this article, you’ll understand why battery testing is so critical and how these tests help you make smarter choices when selecting batteries.

Stay with us, and we’ll help solve any questions or concerns you have about lithium battery testing. Let’s get started!

Table of Contents

ToggleUnderstanding international testing standards

When it comes to lithium battery testing, several international standards ensure that batteries are safe, reliable, and compliant with regulations. These standards are accepted worldwide, and understanding them is crucial for manufacturers, importers, and consumers alike.

IEC 62133 and UL 2054 The IEC 62133 and UL 2054 are two of the most widely recognized safety standards for lithium batteries.

IEC 62133 is an international standard that covers the safety requirements for portable sealed secondary cells and batteries. It is recognized globally, particularly in Europe, Asia, and other parts of the world. This standard ensures that lithium-ion batteries can withstand electrical, mechanical, and thermal stresses without posing safety risks. Learn more about IEC 62133 here.

UL 2054 is an American standard for household and commercial batteries. It focuses on the safety of rechargeable batteries used in a wide range of devices, from power tools to medical equipment. This standard is recognized primarily in North America and is accepted by various countries that follow U.S. Regulations. Learn more about UL 2054 here.

UN38.3 Testing Requirements for Safe Transport

Lithium batteries are considered hazardous goods, so they must meet specific safety tests before being shipped. UN38.3 sets the testing requirements for lithium batteries intended for air and sea transport. These tests ensure that the batteries won’t cause fires or explode during transport.

In China, several organizations conduct air and sea transportation reports that meet UN38.3 requirements, including:

- DGM: A leading provider of dangerous goods logistics services.

- The Second Research Institute of CAAC: A government institute that provides testing for lithium battery transport.

- CVC: A recognized testing and certification body.

- GHS: Global Harmonized System, which is responsible for classification, labeling, and packaging of hazardous substances.

The Role of ISO Standards in Lithium Battery Testing

ISO (International Organization for Standardization) plays a key role in ensuring the quality and environmental safety of lithium batteries. Two important ISO standards are:

- ISO 9001: This standard focuses on quality management systems. For lithium battery manufacturers, it ensures that the production processes meet high-quality standards.

- ISO 14000: This standard focuses on environmental management, helping manufacturers minimize environmental impacts throughout the battery’s lifecycle.

Common Battery Testing Mistakes and How to Avoid Them

Battery testing requires careful attention. Here are some common mistakes and tips on how to avoid them:

- Skipping standard testing procedures. Always follow the required standards to ensure safety and compliance. Missing tests can lead to unsafe battery use.

- Using the wrong testing equipment. Ensure you’re using the correct tools for each test. Inaccurate results can lead to dangerous situations.

- Not conducting environmental testing. Batteries need to be tested for extreme conditions. Don’t neglect tests for temperature, humidity, and vibration.

- Failing to test abuse scenarios. Always test for scenarios like short circuits and overcharging. These tests are critical to prevent accidents.

- Overlooking battery aging tests. A battery’s performance degrades over time. Test for cycle life and long-term performance to ensure reliability.

By following proper standards and avoiding these mistakes, you’ll ensure that your lithium batteries are safe and reliable.

Types of lithium battery testing

Lithium batteries are tested in various ways to ensure they work properly and safely. These tests are essential for understanding how a battery will perform under different conditions. In this section, we’ll give you an overview of the main types of tests lithium batteries go through.

Performance Testing for Reliability

Performance testing is crucial to ensure a battery works as expected over time. It checks things like battery capacity, how much power it can deliver, and its efficiency. One key part of this testing is capacity testing, which measures how much energy the battery can store and how long it lasts under normal use. Another important aspect is cycle life testing, where the battery is charged and discharged repeatedly to see how well it holds up after many cycles. This helps determine its longevity and reliability.

Safety Testing for Protection Against Hazards

Safety is the top priority when it comes to lithium batteries. These batteries are tested to make sure they won’t cause harm, such as catching fire or leaking, during use. Some of the tests in this category include:

- Short-circuit and overcurrent protection to prevent overheating.

- Thermal runaway and fire resistance tests to make sure the battery won’t overheat and cause fires.

- Overcharge and over-discharge protection to ensure the battery doesn’t fail if it’s charged or discharged too much.

Environmental Testing for Harsh Conditions

Lithium batteries can be exposed to extreme conditions, so it’s important to test how they perform in these situations. Environmental tests check how batteries behave in:

- High and low temperatures: Batteries are tested to see how they perform in both hot and cold environments, which can affect battery life and safety.

- Vibration and shock: These tests ensure that the battery stays safe and works well when exposed to movement or impact, like in electronic devices or vehicles.

Testing for Different Lithium Battery Types

Different types of lithium batteries require different testing approaches. For example:

- 18650 batteries are often used in electric vehicles and laptops. Testing focuses on capacity, cycle life, and safety under stress.

- LiPo (Lithium Polymer) batteries are lightweight and flexible, commonly used in drones. They need special tests for their ability to handle high discharge rates and physical impacts.

- LiFePO4 (Lithium Iron Phosphate) batteries are known for their stability and long lifespan. Testing ensures they perform well at high temperatures and have good thermal stability.

These tests make sure each type of lithium battery meets the required safety and performance standards.

Battery safety tests

Safety is the top priority when designing and manufacturing lithium batteries. A failure in battery safety can result in dangerous consequences, such as fires, explosions, or loss of power. To ensure that batteries are safe for everyday use, they undergo a series of rigorous safety tests. Let’s take a closer look at some of these critical tests.

Short-Circuit and Overcurrent Protection Tests

Lithium batteries can fail if there is a short circuit or an overcurrent situation. In this test, the battery is intentionally subjected to short-circuit conditions or excessive currents to ensure it can withstand these situations without causing damage. The goal is to test the battery’s built-in protection circuits to stop the flow of power before the battery overheats or causes a fire.

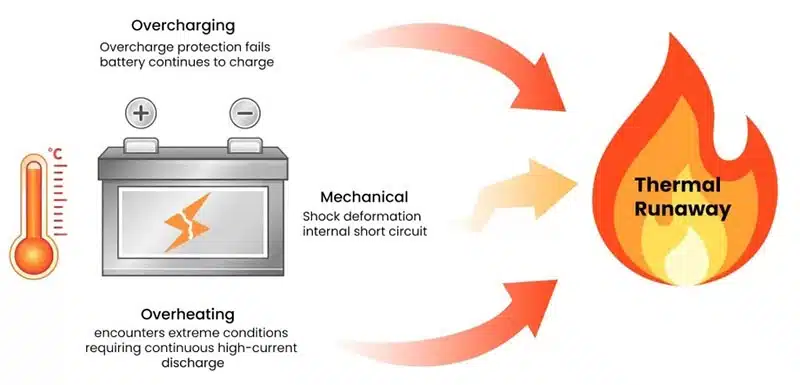

Thermal Runaway and Fire Resistance Testing

Thermal runaway is a condition where the battery’s temperature rises uncontrollably, potentially leading to a fire or explosion. In this test, the battery is exposed to high temperatures or extreme charging conditions. The battery’s response to overheating is carefully monitored to see if it can safely handle the heat or if it fails by catching fire or releasing harmful gases. Fire resistance testing is crucial, especially for batteries used in consumer electronics, electric vehicles, and other high-risk applications.

Overcharge and Over-discharge Protection Testing

Lithium batteries can be damaged or become hazardous if they are overcharged or over-discharged. These tests ensure the battery’s protection mechanisms prevent these conditions. In an overcharge test, the battery is charged beyond its rated voltage to see if it can safely shut down before damage occurs. Over-discharge testing involves draining the battery beyond its normal capacity to check that it doesn’t cause failure or safety hazards.

Vibration, Shock, and Impact Testing for Durability

Batteries are often subjected to physical stress, especially in mobile devices, vehicles, and industrial equipment. Vibration, shock, and impact testing simulates the types of mechanical stress a battery might experience in real-world conditions. This test ensures that the battery can withstand drops, vibrations, and shocks without leaking, swelling, or malfunctioning.

In-Depth Look at Battery Abuse Testing

Battery abuse testing goes beyond standard safety checks. This includes subjecting the battery to extreme conditions that simulate real-life accidents. For example, batteries are punctured, crushed, or exposed to extreme temperatures. This type of testing is critical for understanding the battery’s behavior under severe abuse and ensures it can handle worst-case scenarios without posing a risk to users.

Why Testing Battery Safety is Necessary

Testing battery safety is vital not only to ensure that a battery performs as expected, but also to prevent dangerous situations. A battery that isn’t thoroughly tested can cause fires, chemical leaks, or even explosions. These risks make safety testing an essential part of the battery development process. Manufacturers need to test every aspect of the battery’s safety to comply with industry standards and provide reliable products to consumers.

| Test Type | Standard | Condition | Result |

| Short-Circuit Protection | IEC 62133 | Short-circuit at various current levels | No fire or excessive heat |

| Thermal Runaway Testing | UL 2054 | Overheated to high temperatures | No thermal runaway, no fire |

| Overcharge Protection | IEC 62133, UL 2054 | Overcharge at rated voltage | Battery shuts down safely |

| Over-discharge Protection | UL 2054 | Discharge below minimum voltage | No internal damage or hazard |

| Vibration, Shock, and Impact | IEC 62133, UN38.3 | Subject to mechanical stress | No leakage or damage |

How Lithium Battery Testing Impacts Environmental Compliance

Battery testing isn’t just about performance; it also plays a role in environmental compliance. Testing ensures that the materials used in the battery are safe for disposal and that the battery can be recycled properly. By meeting safety standards, manufacturers also help reduce the environmental impact of battery disposal and recycling.

To learn more about how lithium batteries affect the environment and what measures manufacturers can take to minimize harm, read our full post on how lithium batteries affect the environment.

Capacity and energy density testing

To understand how well a lithium battery performs, we need to look at capacity and energy density. These tests help us figure out how much power the battery can store, how efficient it is, and how long it will last.

How to Measure Battery Capacity and Efficiency

Battery capacity is the amount of energy a battery can store, usually measured in mAh (milliampere-hours) or Ah (ampere-hours). To measure it, the battery is fully charged and then discharged. The amount of energy it delivers before reaching the cutoff point tells us its capacity. In simple terms, it’s how long the battery can power a device before needing to be recharged.

Efficiency is about how well the battery charges and discharges. Some energy is always lost during this process, but a high-efficiency battery loses less power. Testing efficiency shows us how much of the energy used during charging is actually stored and available for use.

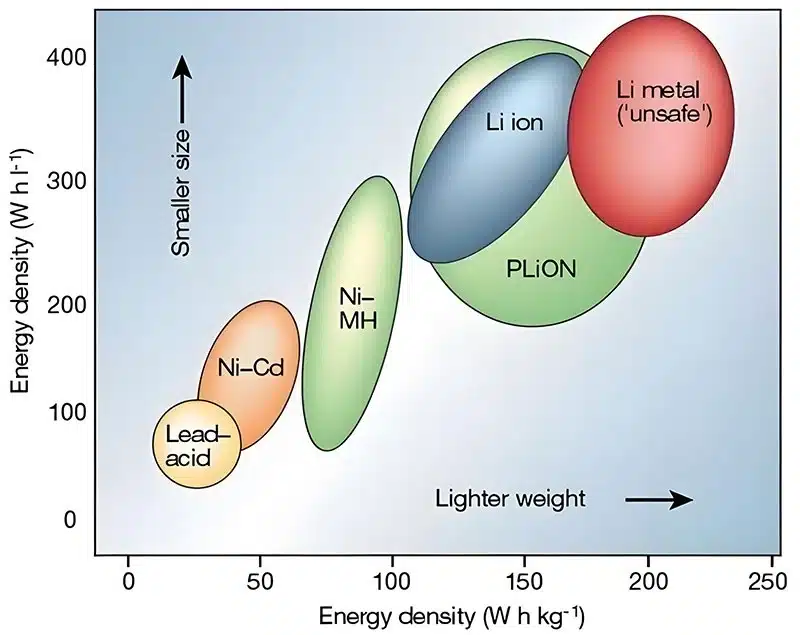

Energy Density and Its Impact on Battery Performance

Energy density tells us how much energy a battery can store for its size or weight. It’s measured in Wh/kg (watt-hours per kilogram). Higher energy density means the battery can store more energy in a smaller space, which is especially important for devices like smartphones or electric vehicles, where size and weight matter.

A battery with a higher energy density allows your device to run longer without adding extra bulk or weight. This makes energy density a key factor in designing better, more efficient batteries.

Cycle Life Testing for Long-Term Performance

Cycle life testing measures how long a battery can last before its performance starts to drop. The battery is charged and discharged over and over again. Each full cycle is counted. Typically, lithium batteries last for several hundred to a few thousand cycles before their capacity begins to degrade.

As batteries go through more cycles, their capacity slowly decreases, which is called aging. Testing helps us predict how a battery will perform over time, allowing manufacturers to improve design and extend battery life.

Temperature and humidity testing

Lithium batteries need to work in a variety of conditions. Testing how they perform in both hot and cold temperatures, as well as in humid environments, is important to ensure they’re reliable and safe.

High-Temperature Endurance Testing

In high-temperature endurance testing, the battery is exposed to heat to see how well it handles extreme conditions. The battery is placed in an environment where the temperature is raised to a set level, often up to 60°C (140°F) or higher, depending on the battery’s design. The test checks if the battery can maintain its performance without overheating, swelling, or losing capacity. Batteries used in things like electric vehicles or outdoor equipment must pass these tests to make sure they can handle hot weather.

Cold Temperature Behavior of Lithium Batteries

Cold temperature testing examines how a battery performs in freezing conditions. When temperatures drop, a battery’s performance can decrease, and it may not charge or discharge properly. During the test, the battery is exposed to cold environments, sometimes as low as -20°C (-4°F). The test checks if the battery can still work effectively in colder temperatures and how much its performance drops. This is especially important for devices used in cold climates, like outdoor gadgets or electric cars.

Humidity and Moisture Sensitivity in Battery Performance

Humidity and moisture can affect a battery’s performance. When a battery is exposed to high humidity, moisture can seep into the battery, potentially causing damage, corrosion, or failure. In this test, batteries are placed in a humid environment to see how they hold up. The test ensures that the battery’s seals are effective, and it can continue to work even in damp or wet conditions. This is important for devices that are used in outdoor or humid environments, such as in tropical climates or during rain.

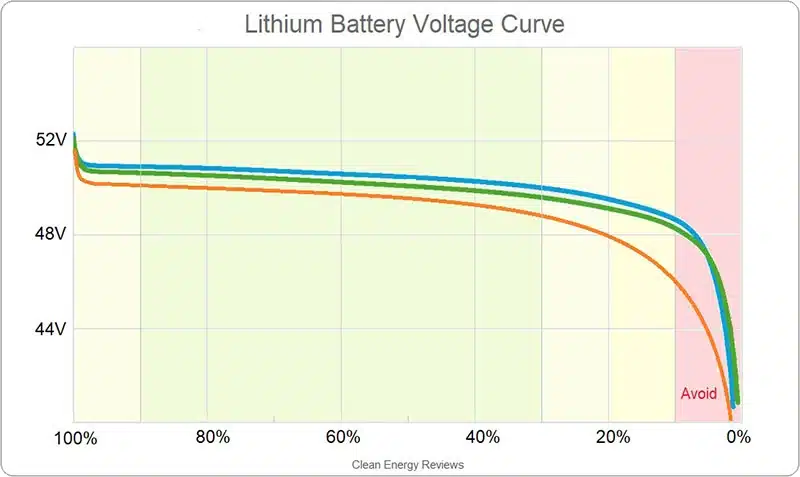

Voltage range and its effect on battery life

Each battery has a voltage range within which it operates safely. If a battery is charged too much or too little, it can lose capacity or even fail. During testing, the battery is charged and discharged within its specified voltage range. This ensures that the battery can handle regular use without degrading too quickly. Keeping the voltage within safe limits helps extend the battery’s life and maintain good performance.

Current Load Testing to Evaluate Performance

Current load testing checks how the battery performs when used under different levels of demand. The battery is subjected to various current loads, which simulate real-world use, such as when powering devices that require high or low amounts of energy. During this test, the battery is discharged at different rates (e.g., high load for fast discharge or low load for slower discharge). This helps us see how the battery performs under stress, including how much power it can provide at peak demand and how long it lasts under different conditions.

Understanding Charge and Discharge Cycles in Testing

Charge and discharge cycles are how we test the battery’s ability to store and release energy over time. A cycle occurs when a battery is charged to its full capacity and then discharged completely. Testing how the battery behaves during multiple cycles helps us understand its long-term performance. It’s crucial to check how the battery’s capacity decreases with each cycle and ensure it still performs well after many uses.

Battery safety and risk assessment

When using lithium batteries, safety is key. These batteries are powerful, but they can also present risks if not handled correctly. Let’s take a look at the potential risks, how to manage them, and the role of safety testing.

Identifying Potential Risks in Lithium Battery Use

Lithium batteries can be hazardous if not used, stored, or disposed of properly. Some of the risks include:

- Overheating: Batteries can get too hot, leading to thermal runaway, which can cause fires or explosions.

- Short-circuiting: This can cause a battery to overheat or leak, creating safety hazards.

- Overcharging and over-discharging: Charging a battery beyond its limits can damage it, while discharging it too much can reduce its lifespan or cause failure.

- Physical damage: Dropping or crushing a battery can cause internal damage and may lead to leakage or fire.

- Moisture and humidity exposure: These can cause corrosion and internal damage to the battery.

To learn more about the risks and how to avoid them, check out this article on battery risks, prevention, and handling.

Risk Mitigation Strategies Through Testing

Testing is crucial to identifying and preventing these risks. Through safety tests, we can simulate worst-case scenarios, such as overcharging, short-circuiting, and exposure to extreme temperatures. By doing this, manufacturers can design batteries with built-in protection features, like thermal cutoffs and overcurrent protection, to reduce the risk of failure or hazards.

Certifications and Compliance for Safety

Several safety certifications and compliance reports are required to ensure batteries meet safety standards. Some of the key certificates include:

- IEC 62133: A standard for portable batteries, ensuring they are safe for consumer use.

- UL 2054: A safety standard in the U.S. for household and commercial batteries, focusing on preventing fire and other hazards.

- UN38.3: A test report required for shipping lithium batteries safely by air or sea, ensuring they won’t pose a risk during transport.

- CE Certification: Ensures that the battery complies with European Union safety standards.

The Impact of Battery Testing on Product Warranty and Liability

Battery testing plays a key role in protecting both manufacturers and consumers. By conducting thorough safety tests, manufacturers can avoid product failures that lead to safety hazards, thus reducing the risk of warranty claims and legal liability. Proper testing also helps ensure that the battery will last for its expected lifetime, maintaining performance and safety standards throughout its use. This protects the manufacturer and boosts consumer confidence in the product.

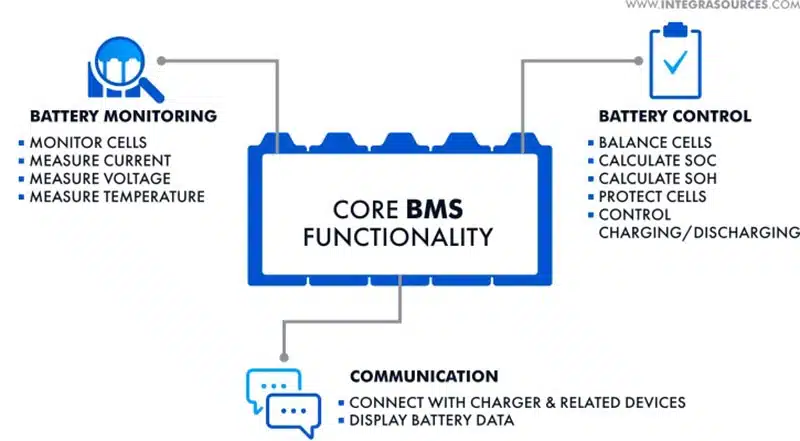

The role of battery management systems (BMS) in testing

Battery Management Systems (BMS) play a crucial role in ensuring that lithium batteries stay safe, perform well, and last longer. A BMS is like the brain of the battery, constantly monitoring its health and making adjustments to protect it from damage.

BMS Functions in Monitoring Battery Health

A BMS keeps an eye on key factors like battery voltage, temperature, and charge level. It ensures the battery doesn’t go beyond safe limits, helping it last longer and perform better. If the battery gets too hot, too full, or if there’s an issue with its voltage, the BMS can take action, like shutting off the battery or reducing the charge to prevent damage.

Testing Battery Protection Features within BMS

A big part of BMS testing involves checking its protection features to make sure they work as intended. Here are some of the key protection features tested:

- Short-circuit protection: Prevents the battery from overheating or causing damage if a short circuit occurs.

- Over-current protection: Stops too much current from flowing, which could damage the battery.

- Over-voltage protection: Ensures the battery doesn’t charge beyond its safe voltage limit.

- Over-charge protection: Stops charging when the battery is full, preventing potential over-heating or fire risks.

These features help the battery stay safe during normal use, and they’re vital in preventing dangerous situations.

How BMS Affects Testing Results and Performance

The BMS can significantly affect a battery’s performance and testing results. A well-functioning BMS ensures the battery operates safely and efficiently, leading to better results in performance tests. For example, the BMS helps the battery manage its energy use, improving its efficiency during discharge cycles.

Lithium Battery Testing for Extreme Applications (Aerospace, Military, and Electric Vehicles)

For extreme applications like aerospace, military, or electric vehicles, the BMS becomes even more important. In these cases, the battery must withstand tough conditions such as high vibration, temperature fluctuations, and high power demands. The BMS helps ensure that the battery stays within safe limits, which is critical for avoiding failures in high-stakes environments. During testing, the BMS’s response to extreme conditions is carefully evaluated to ensure the battery can handle the stress without failing.

Emerging trends in lithium battery testing

The world of lithium batteries is constantly evolving, and so is the way we test them. As technology advances, new testing methods and standards are being developed to keep up with these changes. Here are some of the latest trends in lithium battery testing.

Advances in Solid-State Battery Testing

Solid-state batteries are an exciting new development in the battery industry. Unlike traditional lithium-ion batteries, which use liquid electrolytes, solid-state batteries use a solid electrolyte, making them safer and more efficient. Testing these batteries is more complex, as they require tests for things like ionic conductivity and thermal stability in solid electrolytes. These tests ensure that solid-state batteries can perform well under real-world conditions and offer the promise of higher energy density, longer lifespan, and better safety.

The Rise of Smart Battery Testing Technology

As batteries become smarter, so does the technology used to test them. Smart battery testing tools now use sensors and data analytics to provide more detailed insights into battery performance. These tools can monitor a battery’s health in real-time, track degradation patterns, and even predict future performance. This level of intelligence helps manufacturers create more reliable batteries and allows consumers to monitor the health of their batteries more easily.

Evolving Standards for Sustainable and Eco-friendly Batteries

Sustainability is becoming a bigger focus in the battery industry. New standards are emerging to ensure that batteries are not only safe and efficient but also environmentally friendly. Testing is now being done to evaluate the recyclability of batteries and to reduce the use of harmful materials. Manufacturers are increasingly expected to meet these standards to minimize the environmental impact of their products. Learn more about sustainable lithium battery disposal and recycling in our article on sustainable lithium battery disposal and recycling.

The Role of AI and Machine Learning in Battery Testing

Artificial intelligence (AI) and machine learning are revolutionizing battery testing. These technologies can analyze large amounts of data quickly and accurately, helping engineers predict battery behavior and performance under different conditions. AI can also improve testing efficiency by automating repetitive tasks, making it easier to spot potential issues and improve battery designs. With AI, manufacturers can develop batteries that are not only safer but also more efficient and longer-lasting.

Battery Testing in the Era of 5G and IoT

As the world becomes more connected through 5G and the Internet of Things (IoT), batteries need to support the growing demand for power in smart devices. Testing for 5G and IoT devices focuses on how batteries handle higher power loads and faster charging times. These devices require batteries that can handle quick bursts of energy and maintain efficiency over extended periods. Testing ensures these batteries can meet the needs of an increasingly connected world without compromising safety or performance.

How to choose the right testing method for your lithium batteries

Choosing the right testing method for your lithium battery depends on its intended application. Different devices have different power needs, so the battery must be tested accordingly to ensure it performs safely and efficiently.

Selecting the Proper Testing Protocol Based on Application

For each battery application, there are specific testing protocols to follow. For example, True Wireless Stereo (TWS) earbuds typically use LiPo (Lithium Polymer) batteries because they are lightweight, flexible, and can fit into small spaces. Testing for LiPo batteries focuses on factors like overcharge protection and discharge rates. On the other hand, power tools require 18650 high-rate battery packs, which can deliver higher power output for demanding tasks. Testing for 18650 cells includes high-drain capacity and cycle life tests to ensure they can handle continuous use without failure. Choosing the correct testing method depends on the battery’s function, size, and performance requirements.

Factors Influencing Testing Requirements

Several factors can influence the testing requirements, such as battery size, application type, safety standards, and the environment the battery will be used in. Batteries used in electric vehicles or aerospace applications require more rigorous testing due to the higher risks and power demands. Environmental factors, like temperature and humidity, can also impact how a battery performs, so testing must consider these variables.

The Role of Third-Party Labs in Battery Testing

3rd-party labs play a crucial role in providing independent verification of battery safety and performance. They ensure that the battery meets industry standards and regulatory requirements. Using a certified lab can help provide credibility and ensure the tests are done accurately.

Understanding the Cost of Battery Testing

The cost of battery testing varies depending on the complexity of the tests. For example, an IEC 62133 safety report can cost anywhere between $600 to $1000, depending on the lab and the testing process. Similarly, the UN38.3 testing report, required for shipping lithium batteries safely, can cost around $500. These costs are necessary investments to ensure the battery meets safety regulations and performs reliably in its application.

Conclusion

As technology advances, so too do the testing procedures for lithium batteries. Testing methods are becoming more sophisticated, with new standards and technologies emerging to ensure that batteries remain safe, efficient, and environmentally friendly. From solid-state battery testing to AI-driven testing technologies, the future of battery testing is focused on improving performance and safety while addressing environmental concerns.

The Growing Importance of Safety and Sustainability

Safety will continue to be a top priority in battery testing, especially as batteries are used in more critical applications like electric vehicles, medical devices, and aerospace. In addition, sustainability is becoming an increasingly important factor. Manufacturers are not only focused on making batteries that perform well but also on minimizing their environmental impact through better recycling methods and reducing harmful materials in battery production.

Final Thoughts on Adopting Robust Testing Standards for Innovation

The future of lithium battery testing lies in adopting robust testing standards that evolve with new technology and applications. These standards ensure that batteries are safe, reliable, and capable of supporting new innovations in energy storage, electric transportation, and other emerging technologies. By staying ahead of testing trends and continually improving testing procedures, manufacturers can help drive innovation while ensuring safety and reliability.

We hope this article has answered your questions about lithium battery testing. If you still have any concerns or need further assistance, don’t hesitate to contact us. At Hongyitai, we’re here to help you navigate the world of battery testing and provide you with the support you need.