NMC battery is a mainstream lithium-ion battery. This article comprehensively discusses ternary lithium batteries.

Table of Contents

ToggleWhat is NMC lithium-ion battery

NMC battery is a type of lithium-ion battery. Its name comes from the positive electrode material, which is mainly nickel, cobalt and manganese chemical materials. NMC is the abbreviation of the first letters of these three elements. It has a high energy density, so its endurance is strong.

How NMC batteries work

The charging and discharging process of NMC batteries is actually the movement of lithium ions.

During the charging process, lithium ions separate from the positive electrode material, pass through the small holes in the diaphragm, and are adsorbed onto the negative electrode material.

The discharge process is the opposite, the lithium ions pass through the electrolyte and the separator again and return to the positive electrode. At this time, electrons flow from the negative electrode to the positive electrode from the external circuit, and this flow of electrons forms the current we use to drive the device to work.

NMC battery main components

You can think of an NMC battery as an energy storage system consisting of 4 key components:

The positive electrode is composed of a nickel-cobalt-manganese mixed material, with nickel responsible for providing high capacity and cobalt and manganese helping to provide stable structure and safety.

The negative electrode is the energy storage area of the battery and is mainly composed of graphite, a material that is very good at accepting and storing lithium ions.

The electrolyte allows lithium ions to shuttle back and forth between the positive and negative electrodes. It is mainly in liquid form and contains lithium salts.

The separator is a very thin, porous physical barrier that allows lithium ions to pass through but blocks electrons, thereby preventing the positive and negative electrodes from directly contacting and causing a short circuit.

NMC battery characteristics

The following discusses the key characteristic terms of ternary batteries.

Nominal voltage: 3.7V or 3.6V.

Operating voltage range: 3V ~ 4.2V.

Capacity represents how much charge a battery can store, and is measured in mAh and Ah.

Energy represents the total amount of work a battery can do, which is determined by voltage and capacity. Energy ≈ voltage × capacity.

Energy density is the core advantage of NMC batteries, which refers to how much energy (watt-hours) can be stored per unit weight (kilogram) or unit volume (liter), generally 150 ~ 250 Wh/kg.

Power density represents how quickly a battery can release energy and is often used in applications that require instantaneous high power output.

The C rate describes the size of the charge and discharge current relative to the rated capacity of the battery, that is, the battery charge and discharge speed. 1C generally means that the battery is fully charged or discharged in 1 hour.

The state of charge refers to the current percentage of battery power. 100% SoC is fully charged and 0% SoC is completely dead.

DoD is the other side of SoC. It indicates how much power has been used, also expressed as a percentage. If SoC is 20%, then DoD is 80%.

SoH measures the battery’s current state compared to its new state when it left the factory, which is an important indicator of battery health.

Cycle life refers to how many complete charge and discharge cycles a battery can go through, which is an important indicator of durability and long-term value. The cycle life of NMC batteries is generally 500 to 1,000 times.

NMC battery coulombic efficiency is as high as 99%, coulombic efficiency refers to how much of the charged charge can be discharged. NMC energy efficiency is also relatively high, generally 90-95% or higher. Energy efficiency refers to how much of the charged energy (watt-hour) can be discharged, because there is energy loss during the charging and discharging process.

When NMC batteries are discharged, the voltage usually remains in a relatively stable platform area, and then drops rapidly when they are almost out of power. The output energy is relatively stable, helping you estimate the remaining power through the voltage.

Different NMC battery types

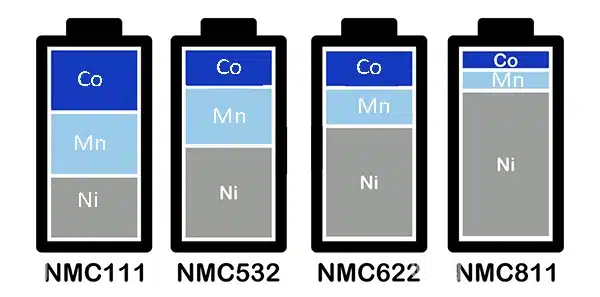

There is more than one type of nickel-cobalt-manganese ratio for NMC batteries. Let’s analyze these different NMC formulas.

NMC111 battery

NMC 111 means the ratio of nickel, manganese and cobalt is roughly 1:1:1. This is an early and balanced formula. It has balanced performance in all aspects and good stability. It can be regarded as a basic model.

NMC532 battery

NMC 532 means the ratio of nickel, manganese and cobalt is 5:3:2. You can see that the proportion of nickel has been significantly increased to increase energy density and thus extend battery lifespan.

NMC811 battery

NMC811 batteries have a nickel content of up to 80% (8:1:1). Its biggest advantage is its high energy density, which can maximize the range of electric vehicles. However, the thermal stability of NMC811 batteries decreases, which also shortens the cycle life.

Now, we are increasingly moving towards cobalt-free batteries because the cost of cobalt is high. In addition, the main production area of cobalt is in the Democratic Republic of the Congo, there are social and environmental problems related to mining, and relying on supply from a single region also poses supply chain risks.

Applications

Electric vehicles are the core and most widely used field of NMC technology. You will see that the vast majority of passenger electric vehicles, especially those that pursue long driving range, tend to choose NMC batteries.

Some high-end consumer electronics products also prefer to use NMC batteries, which can be very thin, have ultra-long battery life, and can meet the specific device battery compartment size.

NMC batteries are also commonly used in handheld power tools, such as electric drills, electric saws, garden tools, etc. It can provide better power density to meet the needs of these tools.

Energy storage systems, whether they are large-scale grid-level energy storage power stations (used for peak and frequency regulation and grid stabilization) or household energy storage devices (such as those used in conjunction with solar panels), are also important application scenarios for NMC batteries.

NMC batteries are also the first choice in applications that are extremely sensitive to weight, such as drones, model airplanes, etc.

NMC battery safety and management

The safety of NMC batteries cannot be ignored. Its thermal runaway risk may be caused by external short circuit, overcharging, physical damage, etc. We need multiple strategies to prevent and control the risk of thermal runaway.

We start to control from the manufacturer’s R&D and production. From the battery cell to the battery pack assembly, effective thermal isolation is achieved through brackets or high-temperature glue. Lithium battery protection board PCM or BMS is essential, which can monitor voltage, current, temperature in real time, balance the charging status of each battery cell, and evaluate the aging of the battery.

To ensure that these safety measures are truly effective, NMC batteries must pass a series of strict international safety standards and tests, such as IEC62133, UN38.3, UL standards. All of our Hongyitai NMC batteries have passed multiple certifications.

How to produce NMC batteries

Manufacturing NMC cells is a very sophisticated process that can be roughly divided into these steps. First, these metal raw materials are processed into specific chemical powders, and then these powders are evenly coated on metal sheets (current collectors). Then, the coated positive and negative electrodes and separators are wound up and assembled into cylindrical steel shells or aluminum plastic films. Then the electrolyte is injected, and finally packaging, formation (first charge activation of the battery) and strict quality testing are carried out. View our lithium battery production process.

The future of NMC battery technology

The future development path of NMC batteries must be to make them more powerful, less expensive and safer. Pursuing a higher nickel content, the latest research shows that NMC batteries reach 9.5.5 (90% nickel, 5% manganese and 5% cobalt each). Decobalting is a core research and development direction, hoping to get rid of dependence on cobalt while maintaining high performance.

Battery performance depends not only on the positive electrode (NMC), but also on the negative electrode. Researchers are developing technologies such as silicon-carbon composite negative electrodes, combining high-energy NMC positive electrodes with high-capacity silicon-based negative electrodes to significantly increase battery energy density.

The direction of electrolyte improvement is new additives and solid electrolytes, replacing flammable liquid electrolytes with solid materials to reduce the risk of fire.

Conclusion

The biggest highlight of NMC batteries is their excellent energy density, which can provide strong endurance or power. There is no absolutely good NMC battery ratio, you need to choose the best NMC formula according to your specific performance requirements.