From smartphones to electric cars to energy storage power stations, lithium batteries are everywhere, profoundly changing the way we live and work. But with the massive use and rapid replacement of these batteries, discarded lithium batteries are piling up at an unprecedented rate. If not handled properly, they will not only pose a fire hazard like a time bomb, but also release heavy metals to pollute our soil and water sources. At the same time, the precious and difficult-to-mine metal resources in the batteries are also wasted.

Therefore, we need more than just simple recycling, but a sustainable disposal and recycling solution. In this article, we will take a deep dive into why sustainable recycling of lithium batteries is so important, revealing how the main recycling technologies currently work, and practical steps that can be taken.

Table of Contents

ToggleWhy lithium batteries need sustainable recycling

Lithium battery recycling is not only a good choice, but also a must. Here is the significance of sustainable recycling of lithium batteries.

Reduce landfill pressure and toxic substance leakage. If used lithium batteries are landfilled like ordinary garbage, they will not only occupy precious land resources, but also heavy metals (such as cobalt, nickel, manganese) and harmful substances such as electrolytes in lithium batteries will leak out, polluting the soil and groundwater, posing a long-term threat to the ecological environment and human health.

Protect key mineral resources. Lithium, cobalt, nickel, etc. in lithium batteries are all important strategic resources, and the mining process is often accompanied by huge environmental damage (such as water consumption and landform destruction) and even social ethical issues.

Lower carbon emissions. Extracting and purifying these metals from their ores consumes a lot of energy and emits a lot of greenhouse gases. In contrast, recycling these materials from used batteries, while also requiring energy, generally results in significantly lower overall energy consumption and carbon emissions. Lithium battery recycling saves more than 60% energy compared to primary mining.

Safety risks should not be ignored. Lithium batteries contain flammable electrolytes. If squeezed, punctured or mishandled, they can easily cause short circuits, thermal runaway, and fires or even explosions. Even storing them at home is risky, and the risks are even greater during waste transportation and disposal.

Circular economic value. Used batteries are not useless garbage. They contain a large amount of valuable metals. Recycling these metals has economic value in itself and can form a new industrial chain. This is a key link in achieving closed-loop resource utilization and an important path to get rid of the linear model of “mining, manufacturing, and discarding” and move towards a sustainable development future.

Lithium battery recycling flow

Lithium battery recycling is like a production line, starting with battery collection, then sent to a specialized factory for sorting, followed by battery disassembly, and the metal materials inside are separated and purified through various technical means. Finally, these recycled materials can be reused to make new batteries or other products.

We take an in-depth look at three representative technologies for lithium battery recycling.

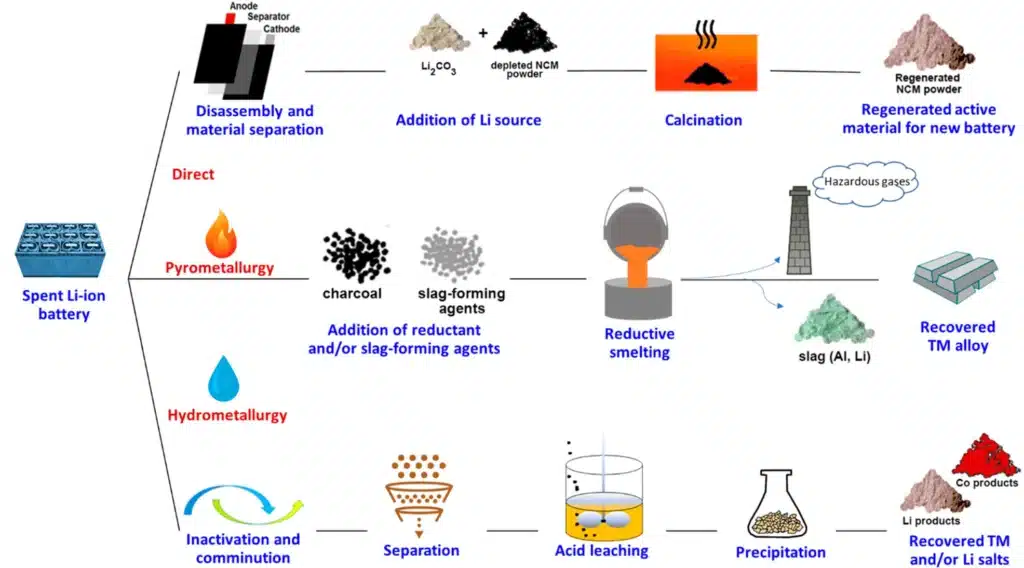

Pyrometallurgy. We can compare it to a big furnace. Throw the battery into the high-temperature furnace to melt it, and then separate the metal. Its advantage is that it can handle batteries of various types and complex components. But it consumes a lot of energy, is not environmentally friendly, has a low recycling rate, and may also cause air pollution.

Hydrometallurgy. You can imagine it as dissolving metals through chemical solutions. It mainly soaks battery materials in chemical solvents such as acids and alkalis, selectively dissolves the target metal, and then purifies it. Its advantage is that it has high purity and efficiency in recovering specific metals (such as cobalt and nickel). However, it requires the use of chemical reagents, which will produce a large amount of acid and alkali wastewater, which may bring secondary pollution risks.

Direct recycling. This is a future direction. Its purpose is to try not to destroy the original structure of the positive and negative electrode materials of the battery, directly repair or regenerate them, so that they can be used again in battery manufacturing. In theory, it has lower energy consumption and can better maintain the original value of the material. However, its technology is still relatively new, and its maturity and large-scale application are limited.

Practical steps for sustainable disposal and recycling

Below we explore specific steps and guidelines from two different perspectives: individual and corporate.

For individual and family users:

Used lithium batteries must not be thrown away like ordinary garbage, nor can they be thrown into ordinary trash cans. You can find local recycling sites. Some large supermarkets (such as Wal-Mart, Carrefour), mobile phone brand stores, large electrical appliance chain stores (such as Suning, Gome), etc. may have recycling bins. Cities or communities set up hazardous waste recycling stations or special battery recycling points. You can also contact Recycling Environmental Center for recycling.

Different recycling points may have subtle requirements, which may require you to pack them in separate bags, insulate the electrodes, and follow on-site instructions.

For businesses and institutions:

Companies are not free to dispose of used lithium batteries as they please, but are subject to laws and regulations, which require compliance with national or local regulations on hazardous waste management, as well as the Extended Producer Responsibility (EPR) system that may be involved.

Enterprises generate a large amount of waste batteries, and they cannot just find a random place to dispose of them like individuals. They must choose a professional recycling service provider that is compliant, qualified, and reputable. This not only depends on the qualifications, but also on the sustainability of its recycling technology and environmental standards.

We recommend internal recycling processes for enterprises. For example, setting up special and safe waste battery collection points in offices and factories to facilitate employees to deposit waste batteries generated at work or personally, and have dedicated personnel to manage them.

This is also a good opportunity to enhance the corporate social responsibility (CSR) image and improve environmental, social and governance performance.

Challenges and prospects for sustainable recycling of lithium batteries

At present, there are many difficulties in recycling lithium batteries. Recycling points are not yet popular and convenient enough, resulting in many batteries not being able to enter the recycling channel. At the same time, the high cost of collecting and transporting used batteries (especially large quantities of batteries) is also a practical problem. There are many types of batteries on the market (with different chemical systems), which brings complexity to recycling. Moreover, the existing technology still has room for improvement in recycling efficiency (especially key materials such as lithium) and the purity of recycled products, which directly affects the economic efficiency and reuse value.

Direct recycling is an advanced and environmentally friendly technology and an important future development direction. It is expected to solve the problems of high energy consumption and low efficiency. Recyclability design is also an important concept, which promotes battery manufacturers to consider the convenience of future recycling when designing batteries, such as easier disassembly and easier separation of materials.

Secondary utilization is an important supplementary capability. For example, batteries discarded in scenarios such as electric vehicles do not necessarily need to be recycled and disassembled immediately. In many cases, they can still be used in energy storage systems with lower requirements, such as home energy storage and grid energy storage.

Policies and industries should work together to deepen the extended producer responsibility system, so that producers (battery manufacturers, car companies, etc.) can take more responsibility throughout the product life cycle, especially during the waste phase. Standards should be unified, such as establishing clear battery labels to facilitate sorting; standards for recycled materials should be established to increase market acceptance.

Conclusion

Sustainable processing and recycling of used lithium batteries is extremely important for environmental protection, resource conservation and safety. We call on individuals and companies to actively adopt the above-mentioned recycling steps, integrate sustainable concepts into daily practices, and ultimately achieve a closed loop of battery resources.