Lithium battery corrosion is a common but often overlooked problem. Studies show that 85% of lithium battery failures are caused by internal corrosion, and the right protective measures can extend the battery life by 3 times. This article will provide you with a complete solution from identifying symptoms to preventive treatment, helping you avoid thousands of dollars in battery replacement costs.

Last updated: May 2025 | Estimated reading time: 8 minutes

This article will answer your questions:

- 5 danger signs of lithium battery corrosion, which 90% of people ignore

- Correct emergency treatment methods after the battery is flooded can save more than half of the batteries

- 3 root causes and chemical mechanisms of lithium battery corrosion

- 7 practical tips to extend battery life

- Professional standards for purchasing corrosion-resistant batteries

Table of Contents

ToggleDoes your lithium battery have these symptoms?

If your lithium battery shows any of the following symptoms, internal corrosion has begun: a sudden drop in battery life of more than 30%, abnormal heating during charging, slight deformation of the battery casing, a pungent odor during use, or the device frequently shuts down automatically. If these early signs are ignored, they may lead to complete battery failure or even safety hazards.

Lithium battery corrosion is a gradual process, and the initial symptoms are often subtle. When you find that the range of your electric car has dropped from 60 kilometers to 40 kilometers, or your mobile phone needs to be charged twice a day, the corrosion may have been going on for several months. What’s more serious is that internal corrosion will produce flammable gases such as hydrogen, increasing the risk of fire. Avoiding these symptoms early can help you avoid the loss of 7,000 yuan in battery scrapping.

Detailed explanation of 5 key corrosion signs

A sharp drop in capacity is the most obvious sign of corrosion. Normally, the annual capacity decay of lithium batteries should be 5-8%. If it drops by more than 20% in a short period of time, it means that the internal electrolyte has begun to decompose and the electrode material is dissolving. If it continues to be used, this may accelerate the corrosion process.

| Corrosion Level | Capacity Loss | Appearance Change | Practical Significance to You |

|---|---|---|---|

| Slight Corrosion | 10-20% | No significant change | Timely treatment can restore 80% performance |

| Moderate Corrosion | 20-40% | Slight heating | Requires professional inspection, may need replacement |

| Severe Corrosion | Above 40% | Deformation/Leakage | Stop using immediately, poses a safety hazard |

Corrosion self-inspection checklist

- Appearance inspection: Is there any white powdery substance or green spots on the battery surface?

- Temperature test: Is the battery temperature above 40°C during normal use?

- Odor identification: Is there any sour, metallic or other abnormal odor?

- Performance monitoring: Is the charging time significantly prolonged, or is the discharge too fast?

A user in Hunan had his 72V electric vehicle battery pack flooded after a heavy rain, which initially only slightly reduced the battery life. However, due to the lack of timely treatment, the battery was completely scrapped three months later, resulting in a loss of 8,000 yuan. If the emergency treatment process had been followed immediately, at least 60% of the battery performance could have been saved.

What should I do if the battery gets soaked with water or damp?

The first 24 hours after the battery is flooded is the critical rescue period. Immediately disconnect the power, move to a dry place, clean the surface moisture with absorbent materials, and then let it stand for at least 48 hours to completely dry. Do not charge or use it immediately, as this may cause a short circuit or even a fire. This can save 50-70% of the battery function.

When lithium batteries come into contact with moisture, complex electrochemical reactions occur. Moisture combines with the electrolyte to produce corrosive substances such as hydrogen fluoride, which accelerates the corrosion of the aluminum-plastic film and electrode materials. If handled in a timely manner, corrosion damage can be minimized.

5-steps emergency treatment for flooded batteries:

- Immediately disconnect the power: turn off all power switches, unplug the charger, and avoid short circuits

- Safe removal: move the battery to a ventilated and dry room, away from heat and fire sources

- External cleaning: wipe the surface moisture with a dry cloth, do not rub hard to avoid damaging the seal

- Drying treatment: place in an environment of about 25°C, use a dehumidifier to accelerate the drying process

- Testing and evaluation: use a multimeter to test the voltage after 48 hours to determine whether it can be restored to use

Treatment strategies for different water ingress levels:

- Slightly damp: Air dry for 24 hours, and continue to use after normal testing

- Short-term immersion in water (within 5 minutes): Follow standard procedures, with a success rate of about 70%

- Long-term immersion (more than 30 minutes): Professional testing is recommended, and the success rate of self-rescue is only 30%

Even if the appearance of a flooded battery is normal, internal corrosion may have already begun. It is recommended to test the voltage and internal resistance once a month to detect hidden dangers in time. Using a professional battery tester can detect signs of corrosion 6 months in advance.

Why do lithium batteries corrode?

The root cause of lithium battery corrosion is the irreversible chemical reaction between the electrolyte and the electrode material. When the positive electrode material dissolves, the SEI membrane is damaged, or the electrolyte decomposes, corrosive substances will be produced to attack the internal structure of the battery. Once this process begins, it is difficult to reverse, so prevention is more important than treatment.

Lithium batteries contain a sophisticated electrochemical system. The positive electrode material is generally lithium cobalt oxide or lithium iron phosphate, the negative electrode is graphite, and there is a liquid electrolyte between the two. Under ideal conditions, lithium ions move back and forth between the positive and negative electrodes without causing side reactions. However, when the temperature is too high, the humidity is too high, or the charging and discharging is improper, this balance will be destroyed and corrosion will occur.

3 major chemical mechanisms of corrosion:

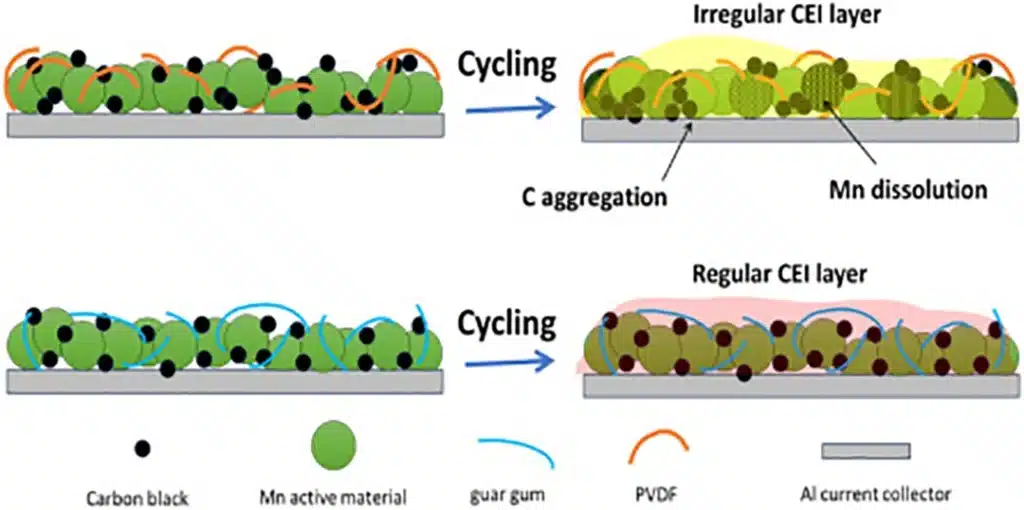

The corrosion mechanism of the positive electrode is the most complicated. When charging, the positive electrode material loses lithium ions and becomes unstable, and easily reacts with the electrolyte. Especially in the overcharge state, the positive electrode material will release oxygen, oxidize the electrolyte to produce organic acid, and further corrode the electrode structure. This is why the life of the overcharged battery is significantly shortened.

Anode corrosion mainly occurs when the SEI film is damaged. The SEI film is a protective layer on the surface of the anode, which is only a few nanometers thick. When the temperature changes drastically or when the battery is deeply discharged, the SEI film will crack, and the electrolyte will directly contact the anode material, causing a reduction reaction to produce gas and sediment.

The decomposition of electrolyte is a catalyst that accelerates corrosion. The main components of electrolyte are lithium salts and organic solvents. When exposed to high temperature or abnormal voltage, they will decompose to produce harmful gases such as hydrogen fluoride and carbon monoxide. These gases not only corrode the inside of the battery, but also increase the internal pressure, causing the battery to swell and deform.

| Corrosion Type | Main Cause | Chemical Reaction | Prevention Method |

|---|---|---|---|

| Positive Electrode Corrosion | Overcharging, High Temperature | Dissolution of metal ions | Control charging voltage and temperature |

| Negative Electrode Corrosion | SEI film breakdown | Electrolyte reduction | Avoid deep discharge |

| Electrolyte Decomposition | Abnormal Temperature | Oxidation of organic matter | Maintain suitable operating environment |

The influence of environmental factors on corrosion

Temperature is a key factor affecting the rate of corrosion. For every 10°C increase, the chemical reaction rate doubles. This means that a battery operating at 50°C will corrode eight times faster than at 25°C. This is why electric car batteries decay particularly quickly when parked in the sun in the summer.

Humidity is also important. Even well-sealed lithium batteries will have trace amounts of moisture seeping in if they are placed in a high humidity environment for a long time. Moisture reacts with the electrolyte to produce hydrogen fluoride, a highly corrosive acid that can quickly destroy the internal structure of the battery.

How to make batteries last longer and be safer?

Proper use and maintenance can extend the life of lithium batteries from 2 years to more than 6 years. The key is to control the depth of charge and discharge (maintain 20-80% power), avoid extreme temperatures (between -10°C and 45°C), perform regular maintenance checks, and choose the right charging equipment. These simple measures can reduce the risk of corrosion by 90%.

The key to preventing corrosion is to maintain the chemical balance inside the battery. Just like maintaining a car engine, lithium batteries also need regular “maintenance”. The difference is that battery maintenance is more reflected in daily usage habits rather than complex maintenance procedures.

7 Golden Rules for Extending Battery Life:

Optimizing charging habits is the most important maintenance measure. Avoid charging after full discharge, which will cause irreversible damage to the SEI membrane. The best practice is to start charging when the power drops to 20%, and stop when it reaches 80%. This “shallow charge and shallow discharge” mode can increase the cycle life from 500 times to more than 2,000 times.

Temperature management is also critical. Create a stable temperature environment for the battery and avoid exposure to the sun and freezing. If you must use it in extreme temperatures, give the battery time to adapt. When going from outdoors to indoors in winter, wait 30 minutes before charging.

Storage environment control is especially important for batteries that are not used for a long time. The ideal storage conditions are a temperature of 15-25°C, a humidity of 45-65%, and a charge level of about 50%. Check the charge level every 3 months and recharge if necessary, but do not fully charge it.

Daily inspection items:

- Observe whether the temperature is normal (not hot) during charging

- Note whether there is any unusual smell or sound

- Check whether the charger indicator light is normal

Monthly in-depth inspection:

- Measure the battery voltage to see if it is within the normal range.

- Check if the casing is deformed or damaged.

- Clean the battery surface and contact points.

Seasonal maintenance:

- Replace aging charging cables and plugs;

- Check whether the battery is securely fixed;

- Evaluate overall performance to see if professional testing is needed

Charging Equipment Selection Guide:

Using an original or certified charger is fundamental to preventing corrosion. Poor quality chargers have unstable voltages, which can cause abnormal reactions inside the battery. Buying a good charger costs less than 5% of the battery price, but can extend the battery life by more than 50%.

How to choose a good battery?

To choose a lithium battery with strong corrosion resistance, you need to consider three key indicators: battery quality (select A-grade battery), packaging process (multi-layer protection design), and BMS system (intelligent management chip). High-quality batteries have 5-10 times stronger corrosion resistance than ordinary batteries. Although the initial investment is 20-30% higher, the total cost of ownership is lower.

The quality of lithium batteries on the market varies greatly, with prices ranging from a few hundred yuan to tens of thousands of yuan. Cheap batteries often cut corners on corrosion protection, using inferior electrolytes, weak packaging materials, or even no basic protection circuits. These batteries will show obvious corrosion after one year of normal use, which is ultimately not worth the cost.

The battery cell grade is the basis for determining corrosion resistance. Grade A batteries use high-purity materials, and the electrolyte formula has been strictly debugged, with impurity content controlled at the ppm level. Grade B or disassembled batteries often use recycled materials or low-grade raw materials to reduce costs, and these impurities will accelerate corrosion reactions.

The packaging process directly affects the sealing performance of the battery. The battery uses high-quality composite aluminum-plastic film and precise edge heat sealing technology, which can effectively prevent moisture from penetrating.

The BMS protection system is an essential configuration for modern lithium batteries. A good BMS can monitor the voltage, temperature, and current of each battery cell, detect abnormalities in time, and take protective measures.

Choosing a reputable brand is the simplest way to ensure quality. Well-known brands invest a lot of resources in the research and development of anti-corrosion technology, and their products are rigorously tested. Certification standards are also very important. Our Hongyitai batteries have corresponding certifications and reports. Click to view certification details.

It is also important to consider maintenance costs. High-quality batteries are simple to maintain and require no additional investment. Low-quality batteries may require frequent replacement of parts and professional repairs, and these hidden costs often exceed the initial price difference.

The latest development and trend of lithium battery anti-corrosion technology in 2025

- Solid electrolyte technology: Toyota, CATL and other manufacturers have launched commercial products, with corrosion resistance improved by 8 times.

- Nano coating protection: Nano protective film technology on the electrode surface can extend the battery life by more than 3 times.

- Smart BMS 4.0: AI-driven battery management system that predicts corrosion risks and proactively prevents them.

Conclusion

Although lithium battery corrosion cannot be completely avoided, its impact can be minimized through proper use and maintenance. The key is to identify corrosion signs early, master emergency treatment methods, develop good usage habits, and choose high-quality battery products. Remember, prevention is better than cure. Investing 20% of your energy in prevention can avoid 80% of the problems.

We at Hongyitai have been focusing on lithium-ion battery production for more than 10 years, providing customized lithium battery solutions for customers in 100 countries and regions around the world. We have 15 patents in anti-corrosion technology, and our products have passed international certifications such as UN38.3 and IEC62133. We provide a full range of services from design to after-sales.

FAQs

Yes, lithium batteries will corrode internally. Although the outer shell is sealed, the electrochemical reaction inside will produce corrosive substances. Especially when it is hot, overcharged or exposed to moisture, the corrosion rate will be greatly accelerated.

Lithium batteries do contain liquid electrolytes, but they are not strong acids but organic solvents. When leaking, they will not corrode the skin like lead-acid batteries, but they are still toxic and corrosive and need to be avoided and cleaned up in time.

Battery swelling is caused by internal gas accumulation, and corrosion is one of the important reasons. When the electrolyte decomposes to produce gas, or the corrosion reaction releases hydrogen, it will cause the battery to swell. If swelling is found, the battery should be stopped and replaced immediately.