Are you also curious about why the range of electric vehicles of different brands varies so much? Today’s smartphones are pursuing extreme lightness and thinness, while the battery life is constantly improving. What is the main reason behind this? Behind these performance differences that we can directly experience in daily life, there is a key driving factor, that is, energy density. This article helps you understand what energy density is and why it is so important.

Table of Contents

ToggleWhat is gravimetric energy density

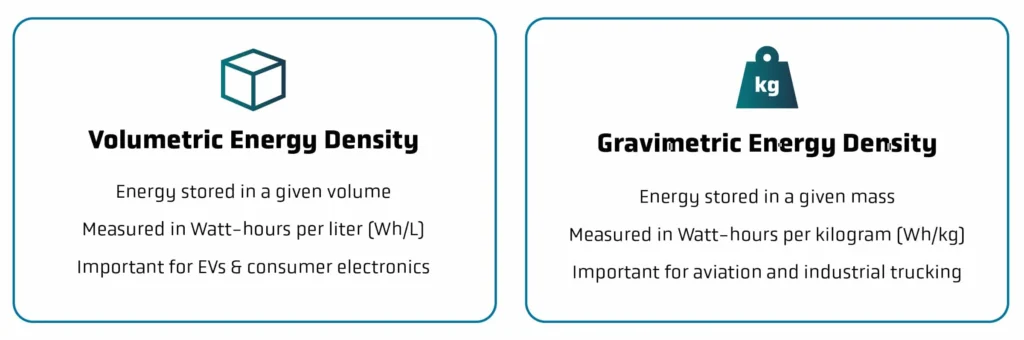

Gravimetric energy density measures how much energy a storage material or device can store per unit mass (per kilogram), and the commonly used unit is Wh/kg. The higher the Wh/kg value, the more energy can be stored under the same weight.

Gravimetric energy density is crucial for applications that are extremely weight-sensitive, such as electric vehicles and drones. When the design goal prioritizes light weight, gravimetric energy density is a core hard indicator.

What is volumetric energy density

Corresponding to weight energy density is volume energy density, which is defined as the energy that can be stored per unit volume (per liter), and the commonly used unit is Wh/L. A higher Wh/L value means that more energy can be stored in the same volume.

Volumetric energy density plays a key role in space-constrained applications, such as TWS earphones, smart watches, and micro-robots that we use in our daily lives.

While energy density (whether by volume or weight) focuses on the total amount of energy stored, a related metric, power density, focuses on how quickly that energy can be released.

The role of energy density

Energy density is not a simple technical indicator, it profoundly affects the feasibility, performance and user experience of the technology.

It makes mobility more convenient. Energy density is one of the important factors that determine the endurance of electric vehicles, which is the main reference factor affecting consumer purchases. The higher the energy density, the longer the vehicle can travel (under the premise that the size and weight of the battery pack remain unchanged).

Energy density is one of the main technical bottlenecks for electric aircraft and drones. The current energy density is the main reason for limiting the development of high altitude, and achieving a major breakthrough in energy density is expected to completely change the development of the aviation industry.

In the products we use in our daily life, such as smartphones, laptops, tablets, wearable devices, etc., people like thin and light products with long battery life. This is why we strive to improve the energy density so that we can provide a variety of forms for everyone to choose from.

Even in large-scale energy storage applications, energy density is equally important, which can significantly reduce the physical footprint required for a project.

Energy density is not the only indicator

Energy density is not the only criterion for measuring the quality of an energy storage technology. When selecting or evaluating a battery technology, we usually look at a comprehensive capability. In addition to energy density, we must also consider the following indicators.

Power density determines the discharge speed. Some applications require the instantaneous release of large amounts of energy, such as rapid acceleration of electric vehicles and instant starting of tools.

Safety is an indicator that everyone is concerned about. Extremely high energy density means that a large amount of energy is concentrated in a small space, which may mean that the material itself is not very stable. Therefore, sometimes in order to ensure absolute safety, some energy density may be sacrificed.

Cycle life refers to how many times a battery can be charged and discharged repeatedly while still maintaining its usable capacity. Long cycle life is critical for applications that require long-term reliable operation (such as electric vehicles and grid energy storage). It is directly related to the total cost of ownership (TCO) and durability of the system. No one likes equipment with a short service life.

Cost is the most realistic factor. Generally speaking, the better the material and the more complicated the process, the higher the price.

How do batteries perform in an environment that is too hot or too cold? The capacity of some batteries will be greatly reduced at low temperatures, or the safety and life will be affected at high temperatures. This must also be considered in practical applications.

Choosing which battery technology to use requires a balancing act. There is no such thing as an absolutely perfect battery, only the one that best suits a particular need.

Energy density of different technologies

Below is a table comparing the energy density of different technologies for your reference.

| Technology Type | Gravimetric Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) | Key Characteristics |

| Lead-Acid | 30 – 50 | 60 – 75 | Mature technology, low cost, heavy, shorter cycle life |

| Nickel-Metal Hydride (Ni-MH) | 60 – 120 | 140 – 300 | Formerly used in hybrid vehicles, better energy density than Lead-Acid |

| Lithium Iron Phosphate (LFP) | 140 – 180+ | 300 – 450+ | High safety, long cycle life, lower cost, moderate energy density |

| NMC/NCA* | 200 – 270+ | 500 – 750+ | High energy density, high performance, higher cost |

| Gasoline | ~12,000 | ~8,760 | Extremely high energy density (chemical), non-rechargeable, low combustion efficiency |

The above values are typical ranges and may vary significantly depending on the specific chemistry, cell design, manufacturing process and stage of technology development.

Conclusion

Gravimetric energy density and volumetric energy density are key quantitative criteria for judging the efficiency of energy storage technology. The improvement of energy density is the core factor driving the development of cutting-edge fields such as the increase in the range of electric vehicles, the thinning of consumer electronic devices, and electric aviation. When choosing a specific battery, you need to comprehensively consider factors such as safety, cost, cycle life, power density, and operating temperature, or contact us to obtain the best lithium battery solution.